Anvick aperture device and method of forming and using same

a technology of aperture device and aperture, which is applied in the direction of building components, structural elements, towers, etc., can solve the problems of increased raw material cost, unfamiliar and unembraced, and increased land and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

—DESCRIPTION

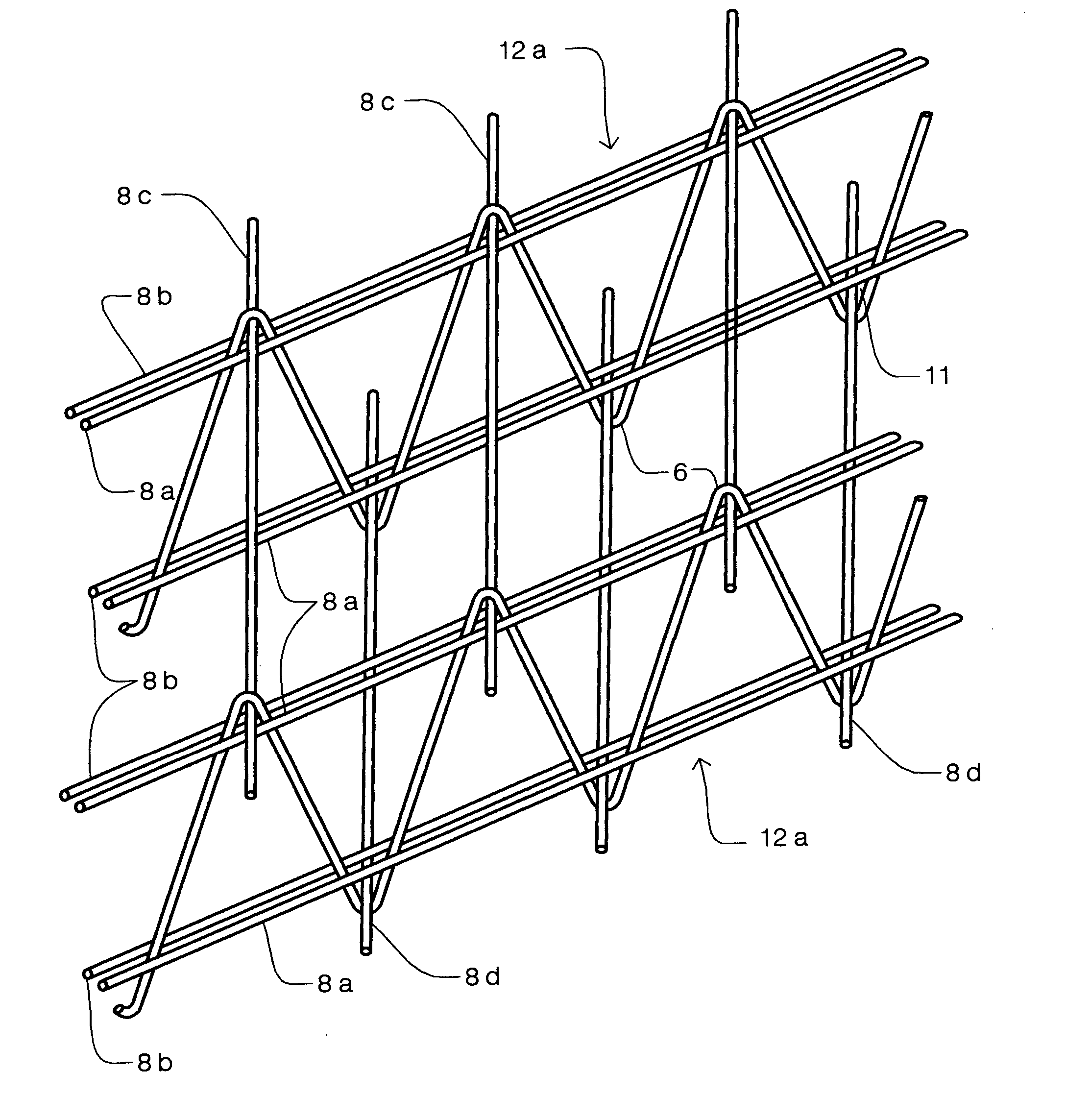

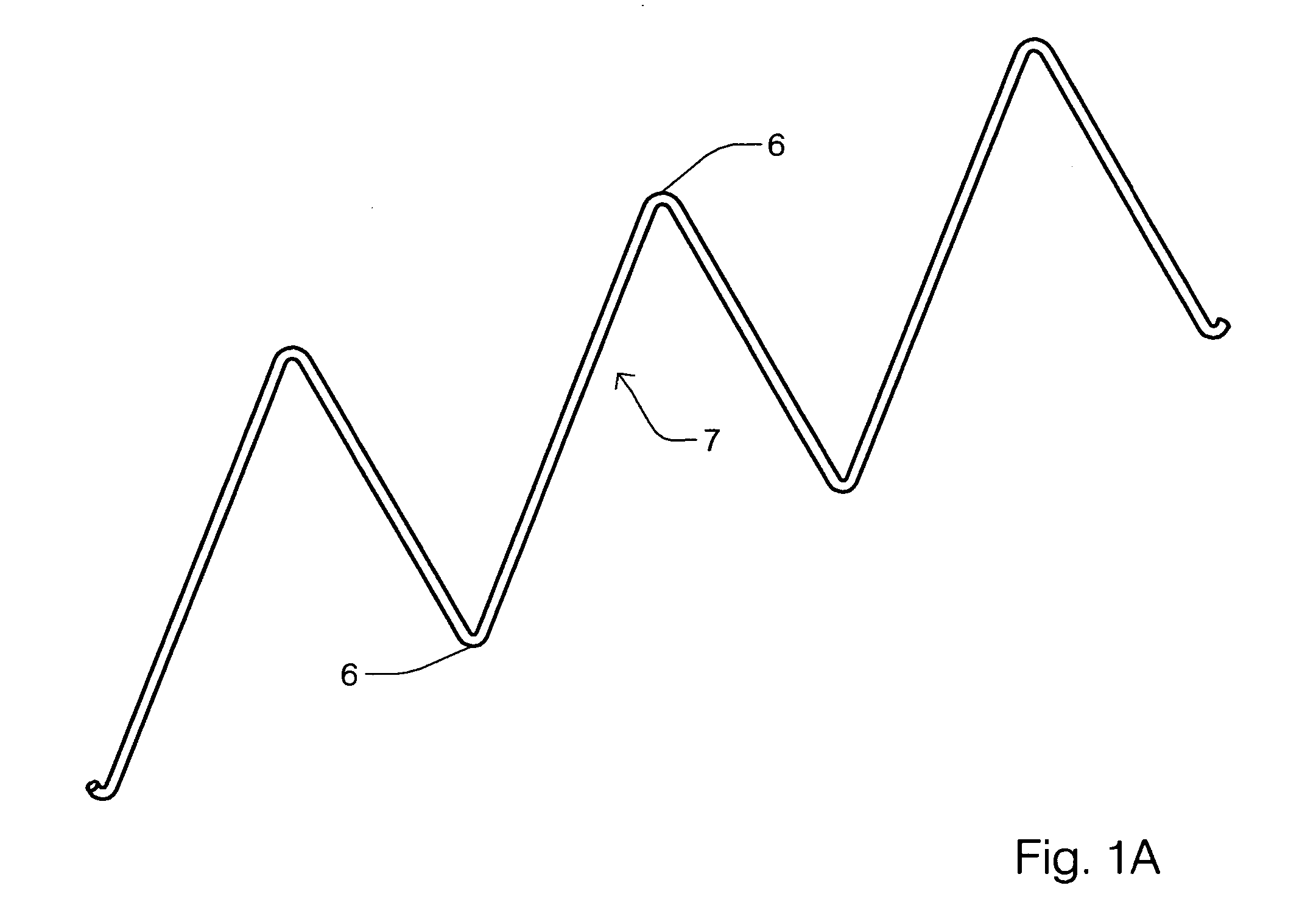

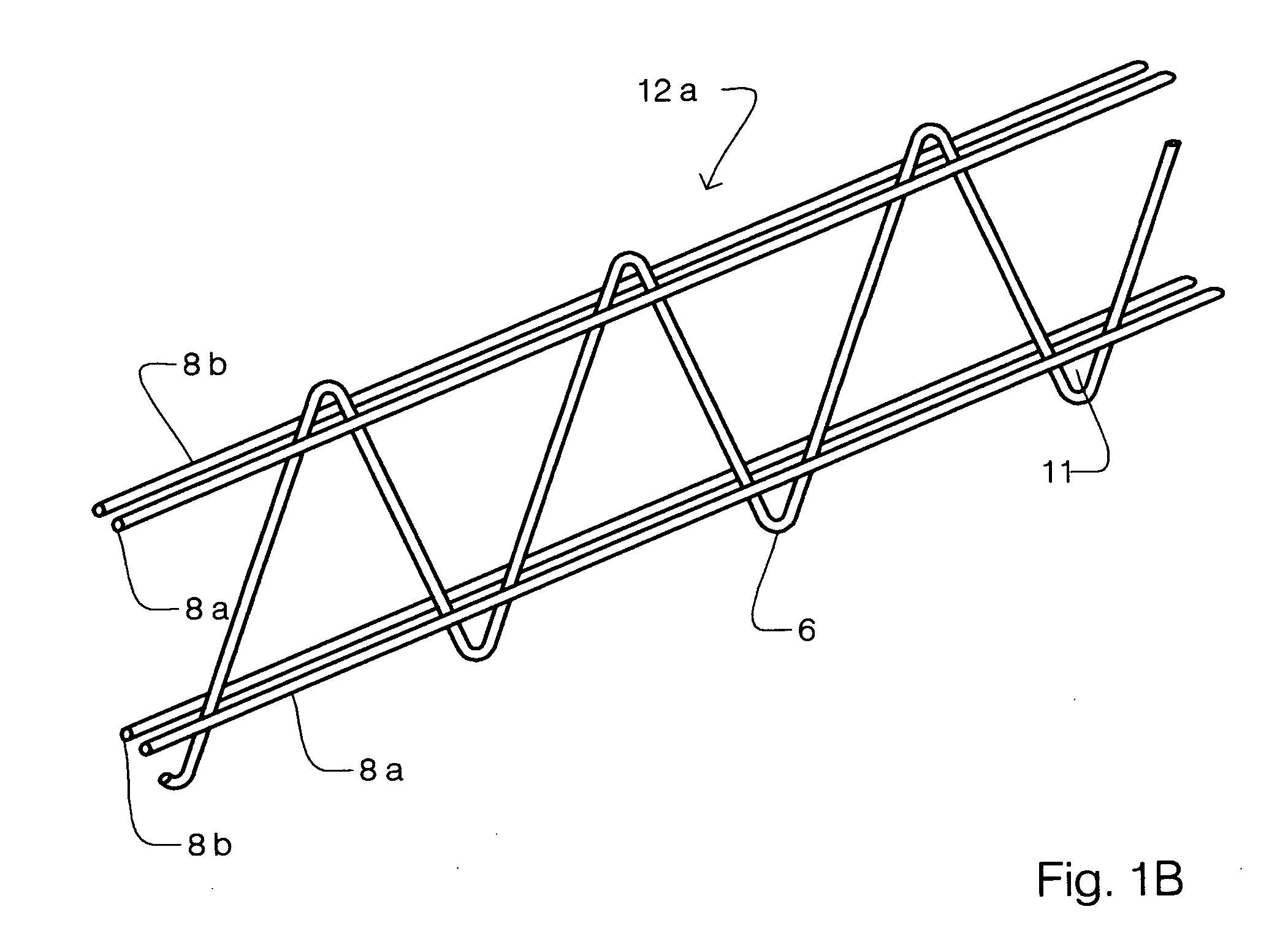

[0074] A preferred embodiment of the aperture 11 of the present invention is comprised of a continuous reinforcement element 7 shown in (FIG. 1A) bent to a curvilinear waveform forming vertices 6 and comprising a web 7 of a truss 12a (FIG. 1B) formed by affixing one or more chords 8a, 8b to said web 7 at a predetermined location such that each vertex 6 extends beyond the attachment location of cords 8a, 8b forming an aperture of predetermined size. An array of reinforcement comprised of a plurality of trusses 12a (FIG. 1B) are integrated into a space frame shown in (FIG. 1D1) of predetermined length, width, and thickness by the insertion and attachment of lateral reinforcement 8c,d of predetermined size through aligned apertures 11 of spaced trusses.

[0075] Truss 12a may be disposed in spatial relationships with its neighbor by elements of an insulative core shown in (FIG. 4A), whose grooved transverse faces 16 fit the central web area of trusses 12a. Space frame (FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com