Bottles, cans, and other storage structures with secondary storage compartments such as cap containers

a storage structure and canning technology, applied in the field of bottles, canning and other types of storage structures, can solve the problems of escaping no matter what the material stored in the bottle, unable to melt chocolate, and prone to melting chocolate, so as to improve the whimsicle and festive nature of the capped bottle, and the odds of being located different

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

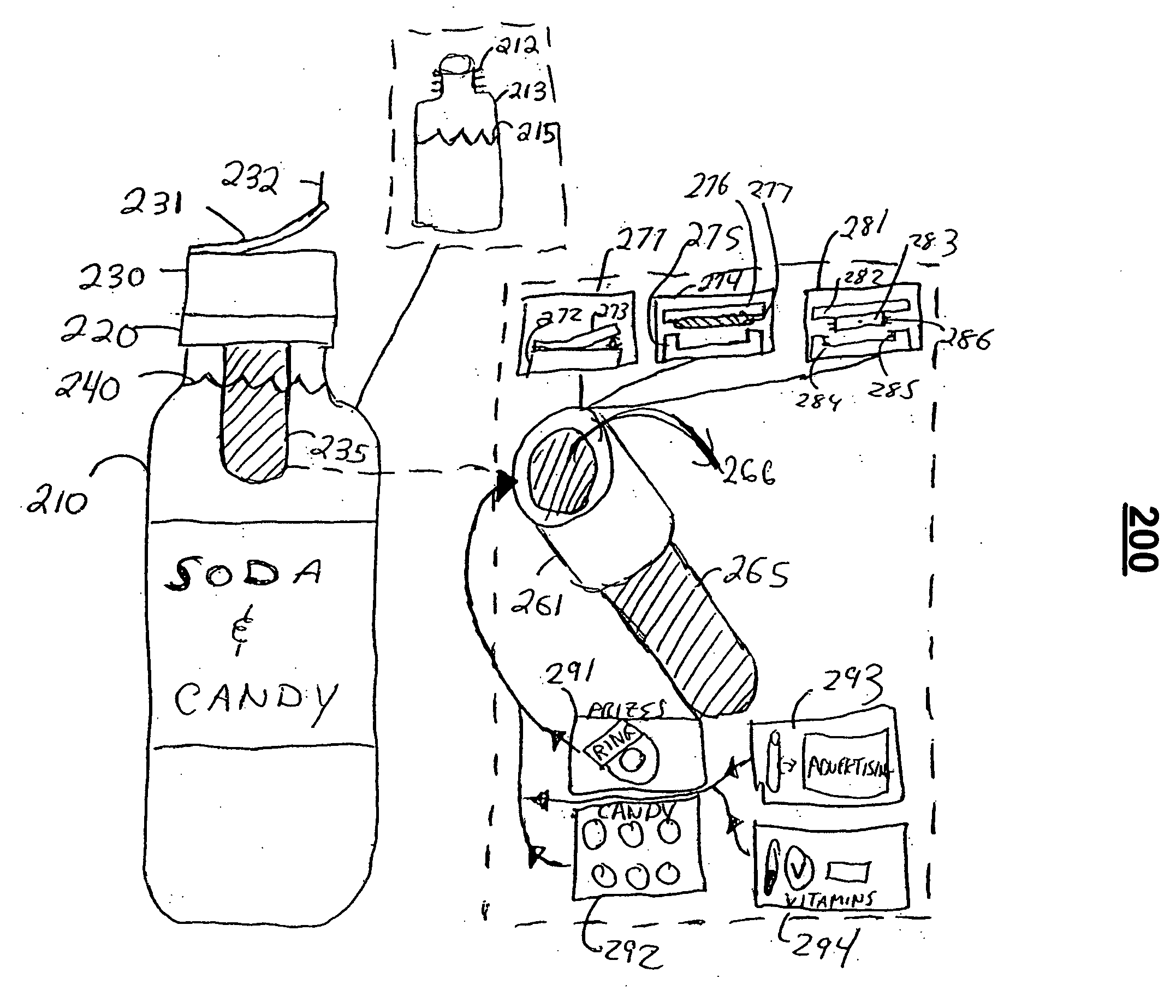

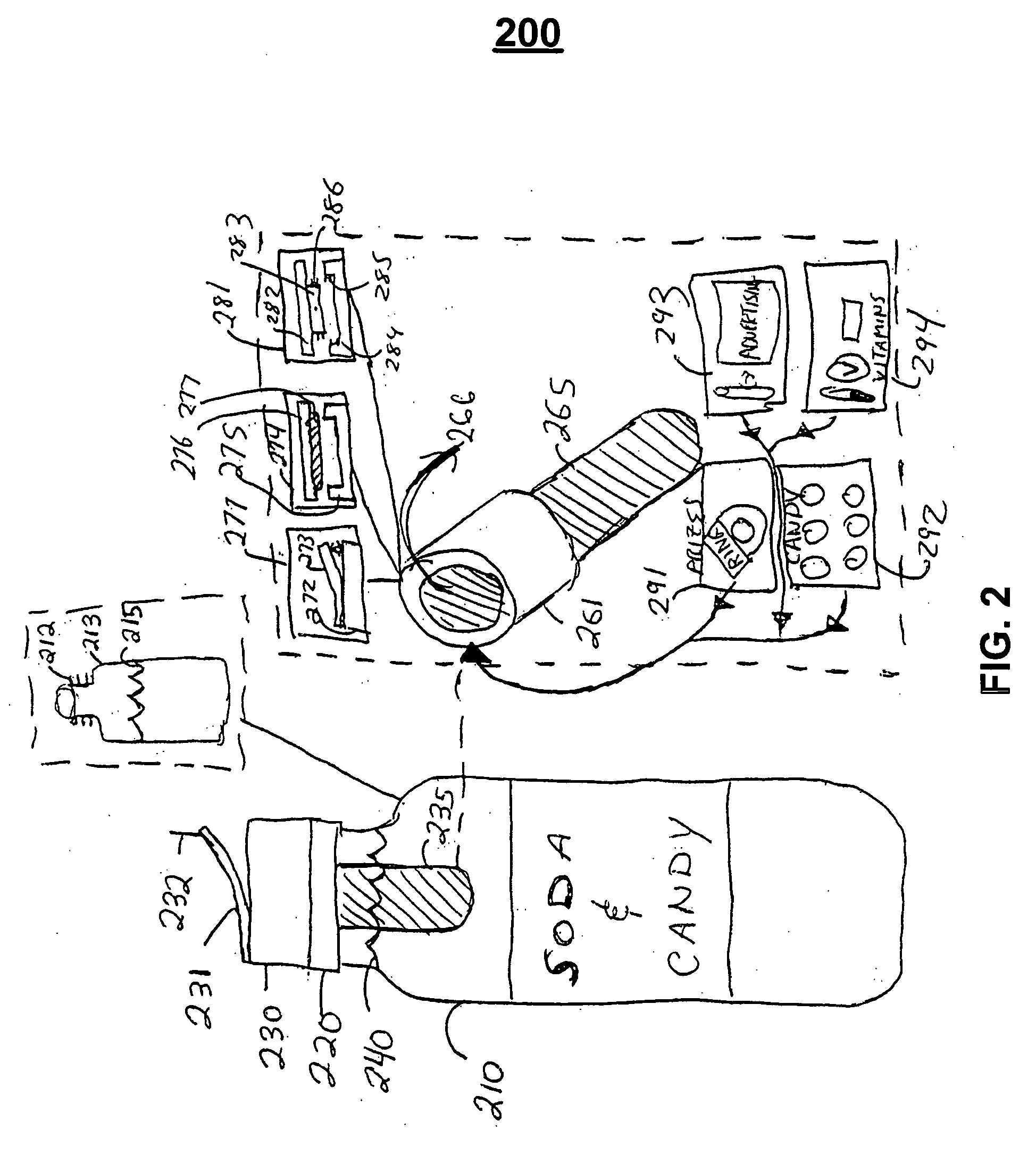

[0028]FIG. 2 shows bottle 210 that may include a removable cap 230 at the mouth of bottle 210. Cap portion 220 may also be provided. Cap portion 220 may be secured to bottle 210 such that, for example, twisting cap portion 220 does not remove cap portion 220 from bottle 210. Cap portion 220 may be removably attached to cap 230 such that the initial removal of cap 230 from bottle 210 (after manufacturing) takes more effort than subsequent removals.

[0029] Cap 230 may include container 235 such that objects (e.g., candy, prizes, a gas, advertising, or a liquid) may be stored in container 235 while other objects (e.g., a liquid) may be separately stored elsewhere in bottle 210. The manufacturing process of a liquid filled bottle may be changed such that less liquid is provided in the bottle before cap 230 having container 235 is placed on bottle 210. Container 235 may take up volume inside of bottle 210. Thus, the amount of liquid initially stored in bottle 210 (or removed from the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com