Height adjustment structure for a canopy

a technology of height adjustment and canopy, applied in the field of canopy, can solve the problems of inability to adjust and height of existing canopy, and achieve the effects of simple structure, convenient use, and change of roof heigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

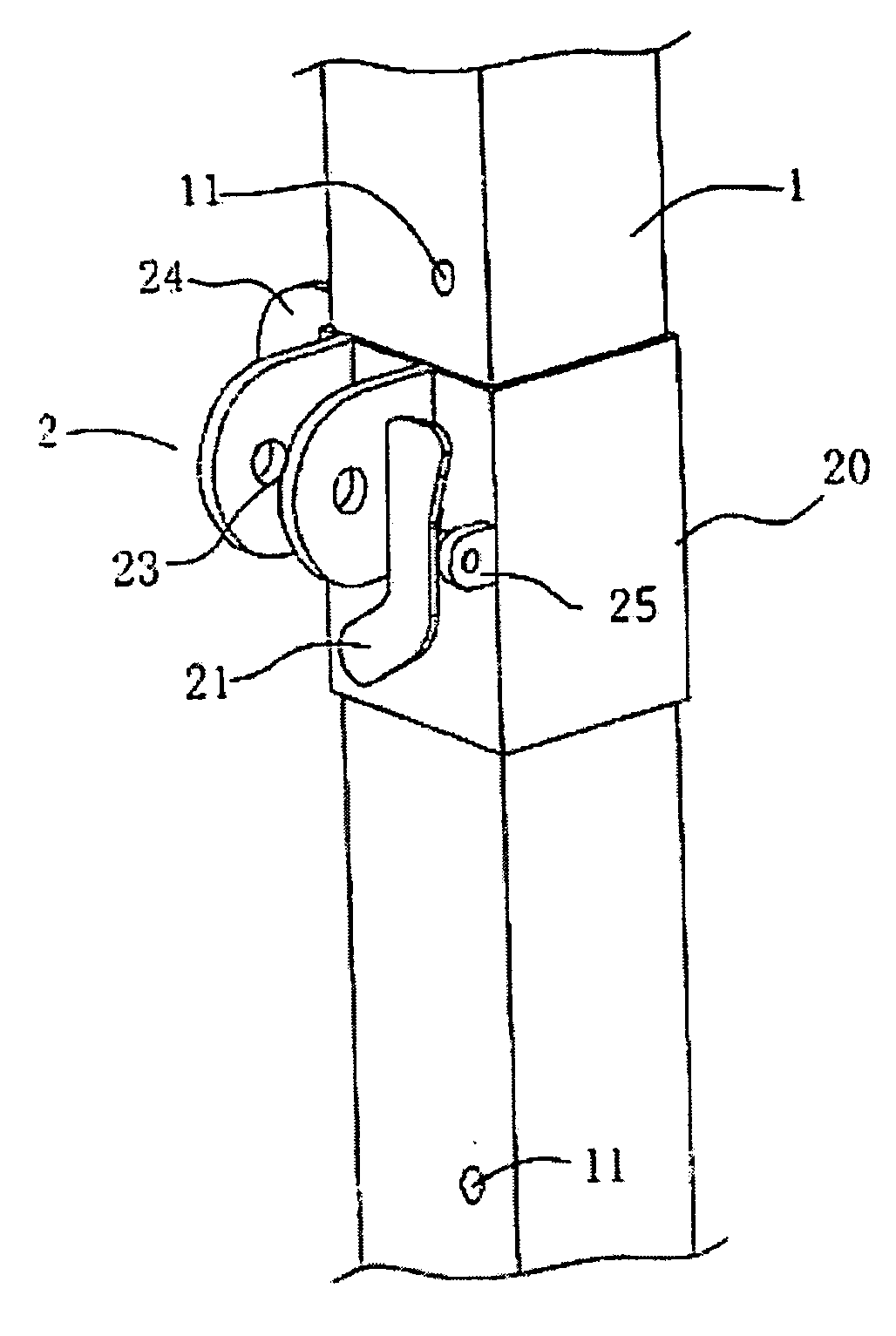

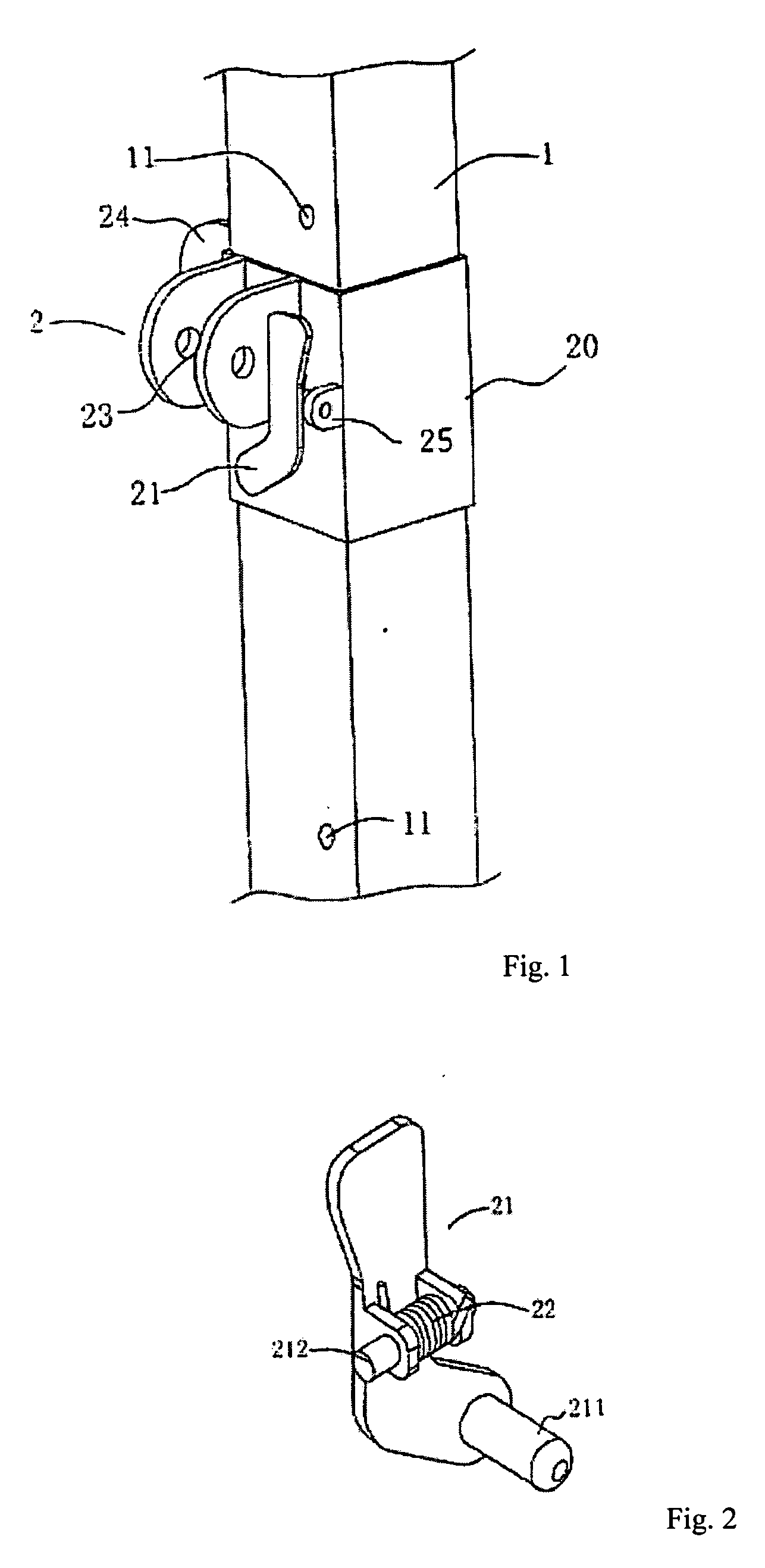

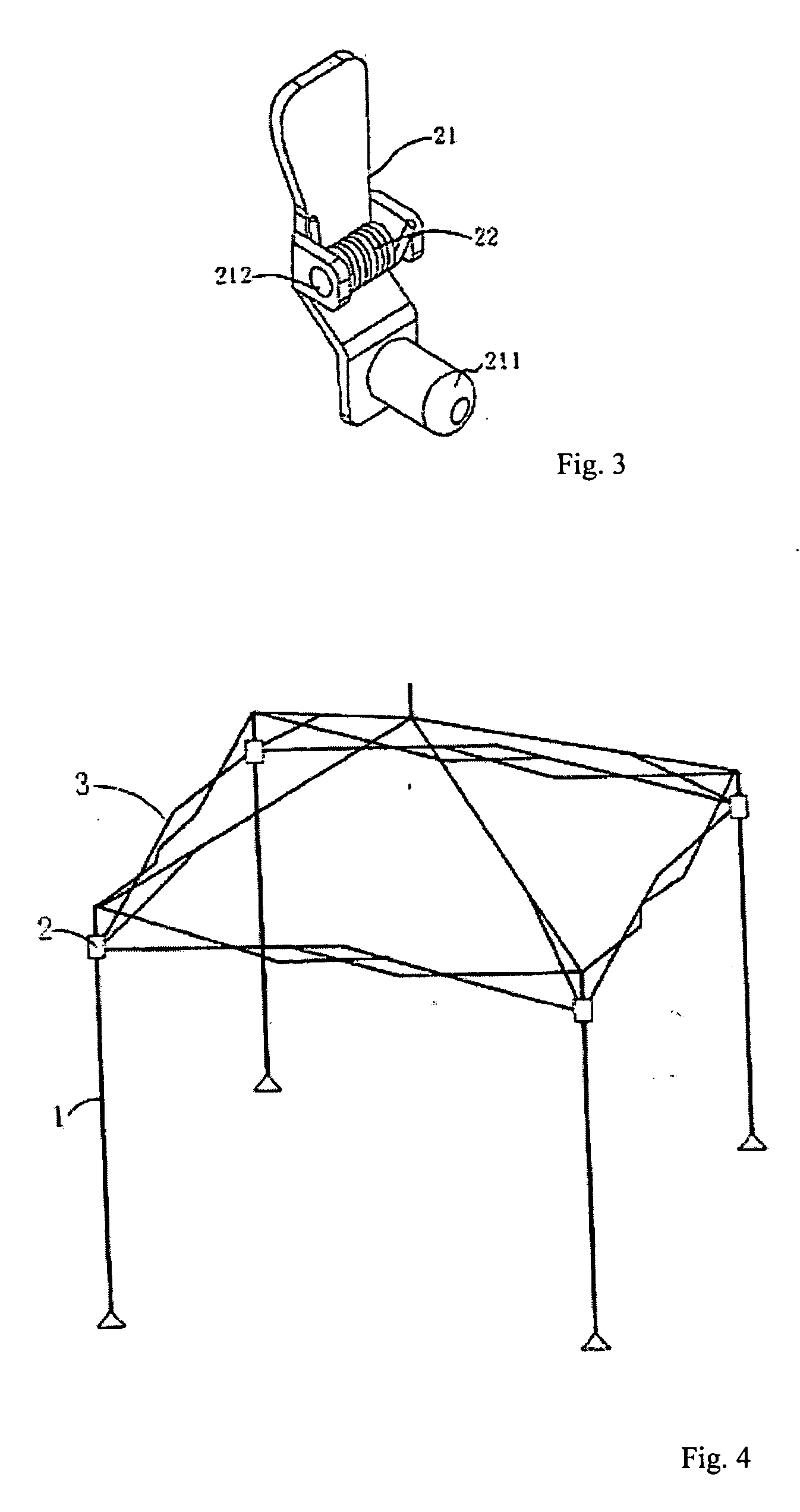

[0015] As shown in FIGS. 1 and 2, a height adjustment structure for a canopy according an embodiment of the present invention includes a vertical pole 1 and a sliding sleeve 2 disposed around the pole. A spring loaded press plate 21 is pivotally mounted on a sidewall 20 of the sliding sleeve 2 between two protruding plates 25 by a mounting pin 212 which extends through a pair of holes on the plates 25. A spring 22 is wound round the mounting pin 212 to bias the press plate 21. One end of the press plate 21 has a locking pin 211 which extend into a through hole (not shown in the drawings) in the sidewall of the sleeve 20. Under the spring tension of the spring 22, the press plate 21 urges the locking pin 211 against the surface of the pole 1 inside the sleeve 20.

[0016] Connecting parts are formed on the sleeve 20 to connect it with other components of the canopy. In the illustrated example, the connecting parts are a pair of plates 23, 24 with through holes.

[0017] In addition, seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com