A pendant combination structure of a super large panel

A combined structure and panel technology, applied in building construction, covering/lining, construction, etc., can solve the problems of multi-hour cost, hanging difficulty, etc., and achieve the effects of low processing difficulty, enhanced strength, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

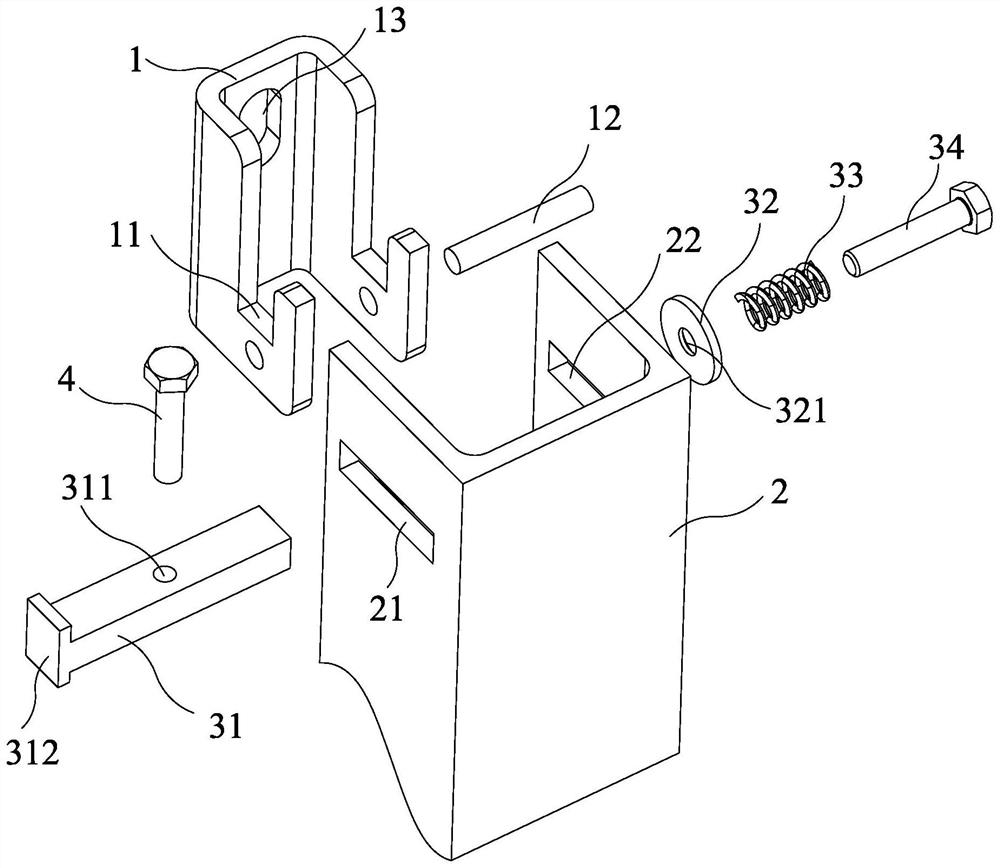

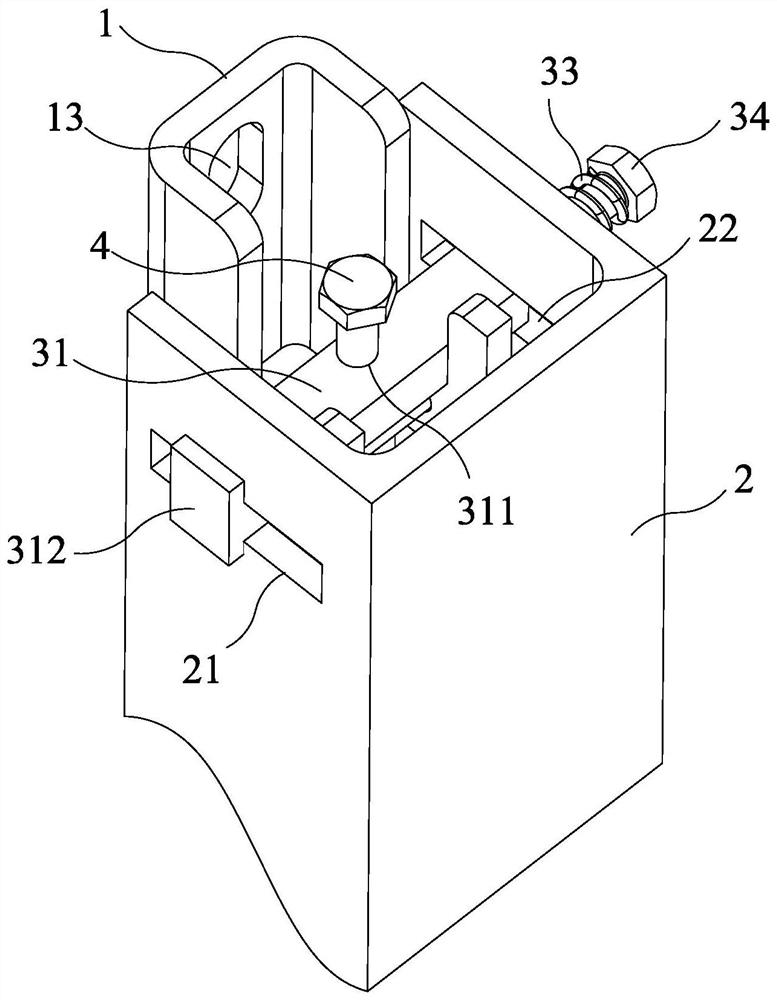

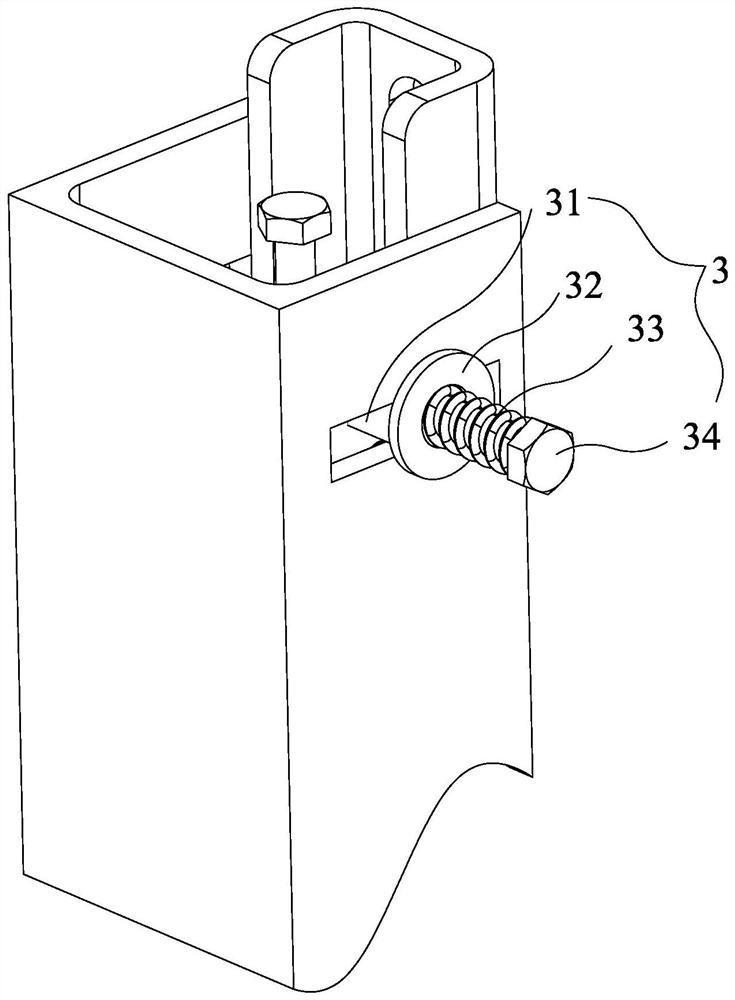

[0026] The present invention provides a pendant assembly structure of a super large panel, such as figure 1 As shown, it includes a wall fixing part 1, a panel fixing part 2, an active connection assembly 3 and a height adjusting bolt 4, such as Image 6 As shown, the movable connection assembly 3 is composed of an adjustment rod 31 , an adjustment piece 32 , an adjustment elastic member and front and rear adjustment bolts 34 , wherein the adjustment elastic member can specifically use a compression spring 33 .

[0027] like figure 1 As shown, the wall fixing part 1 is a hardware part, and the hardware part is bent to form a hook groove 11 with a notch facing upward, so it is also called a hardware bending part. The hardware bending part is stamped and formed by a metal stamping die. The wall fixing member 1 is provided with an anchor bolt fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com