Auxiliary device for large-area laying of ceramic tiles and use method thereof

An auxiliary device and a large-area technology, which is applied in the direction of architecture and building construction, and can solve problems such as empty corners, difficult diffusion of mortar, and corner damage of tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

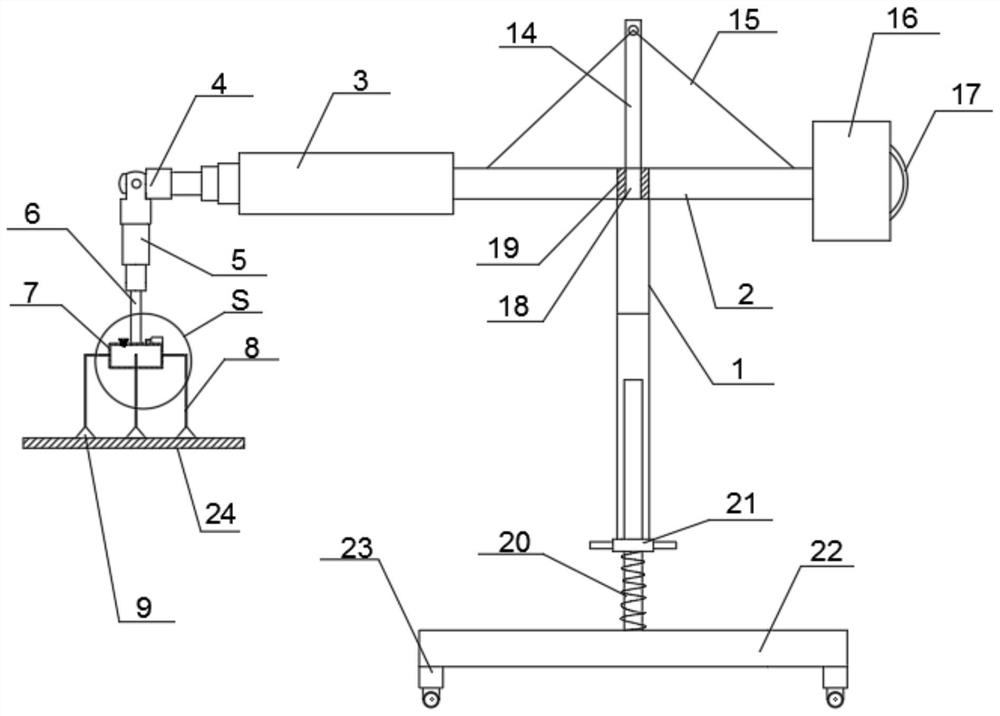

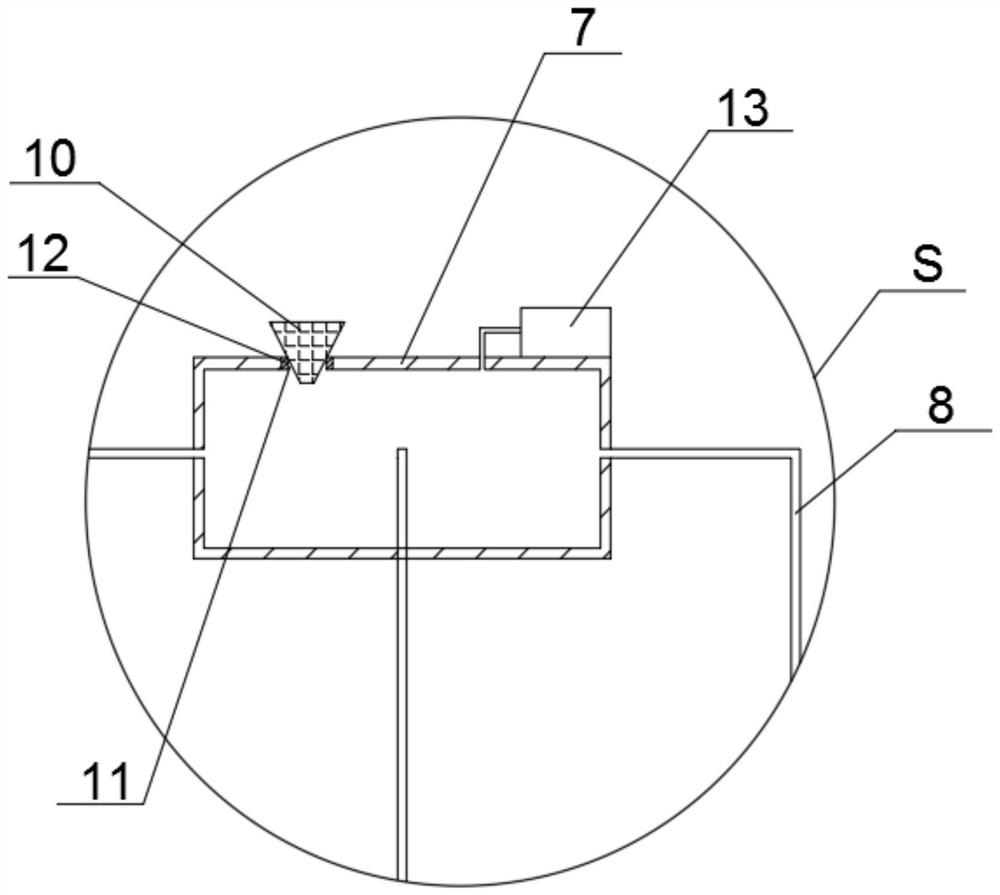

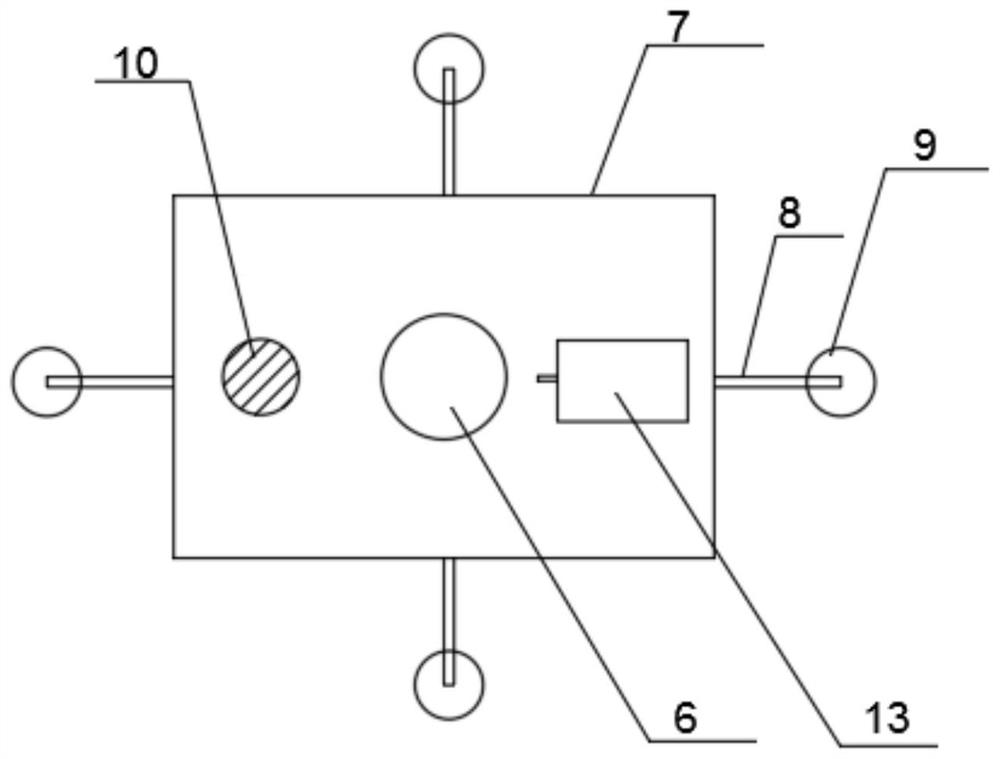

[0032] Such as Figure 1-3As shown, an auxiliary device for laying large-area ceramic tiles, the auxiliary device includes a support rod 1, a telescopic rod 3, a suction cup 9 and a vacuum pump 13, a cross bar 2 is connected to the top of the support rod 1 for rotation, and the bottom end of the support rod 1 Connected with a base 22, one end of the crossbar 2 is connected to the telescopic rod 3, and the telescopic length of the telescopic rod 3 is 3-4m, which increases the coverage area of the auxiliary device, reduces the number of times the auxiliary device moves, and improves the working efficiency. 2. The other end is connected with a counterweight box 16. By adding sand or other items to the counterweight box 16, the added weight matches the weight of the ceramic tile 24, so that the stability of the entire auxiliary device when absorbing the ceramic tile 24 can be maintained, and it is not easy to collapse , causing damage to the ceramic tile 24, one end of the teles...

Embodiment 2

[0034] Such as figure 1 As shown, the lower half of the support rod 1 is set as a hollow structure, the top of the threaded rod 20 is inserted into the inside of the support rod 1, and the lower end of the threaded rod 20 is welded or integrated with the base 22. The area of the base 22 can be slightly larger, increasing the overall auxiliary For the stability of the device, the threaded rod 20 is threaded with the matching adjustment block 21, and by changing the position of the adjustment block 21 on the threaded rod 20, the height of the support rod 1 from the ground is changed, so that the height of the suction cup 9 absorbing the tile 24 can be adjusted in a wide range , the adjustment block 21 can prevent the support rod 1 from sliding down, and the auxiliary device can absorb the tiles 24 from different heights, and the height adjustment structure is simple and easy to operate.

Embodiment 3

[0036] Such as figure 1 As shown, a cylindrical protrusion 18 is integrated in the middle of the top end of the support rod 1 , and a matching bearing 19 is sleeved on the protrusion, and the outer ring of the cross bar 2 is sleeved with the bearing 19 . The support bar 1 and the cross bar 2 are connected by the bearing 19, so that the rotation of the cross bar 2 on the support bar 1 is more sensitive, so that in actual operation, the efficiency of the position movement of the ceramic tile 24 is higher, and the laying progress is accelerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com