Floating protection barrier gate

a floating protection and gate technology, applied in water cleaning, construction, weapons, etc., can solve the problems of low protection or durability of conventional grp port security barrier modules, high maintenance costs, and inability to meet the needs of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

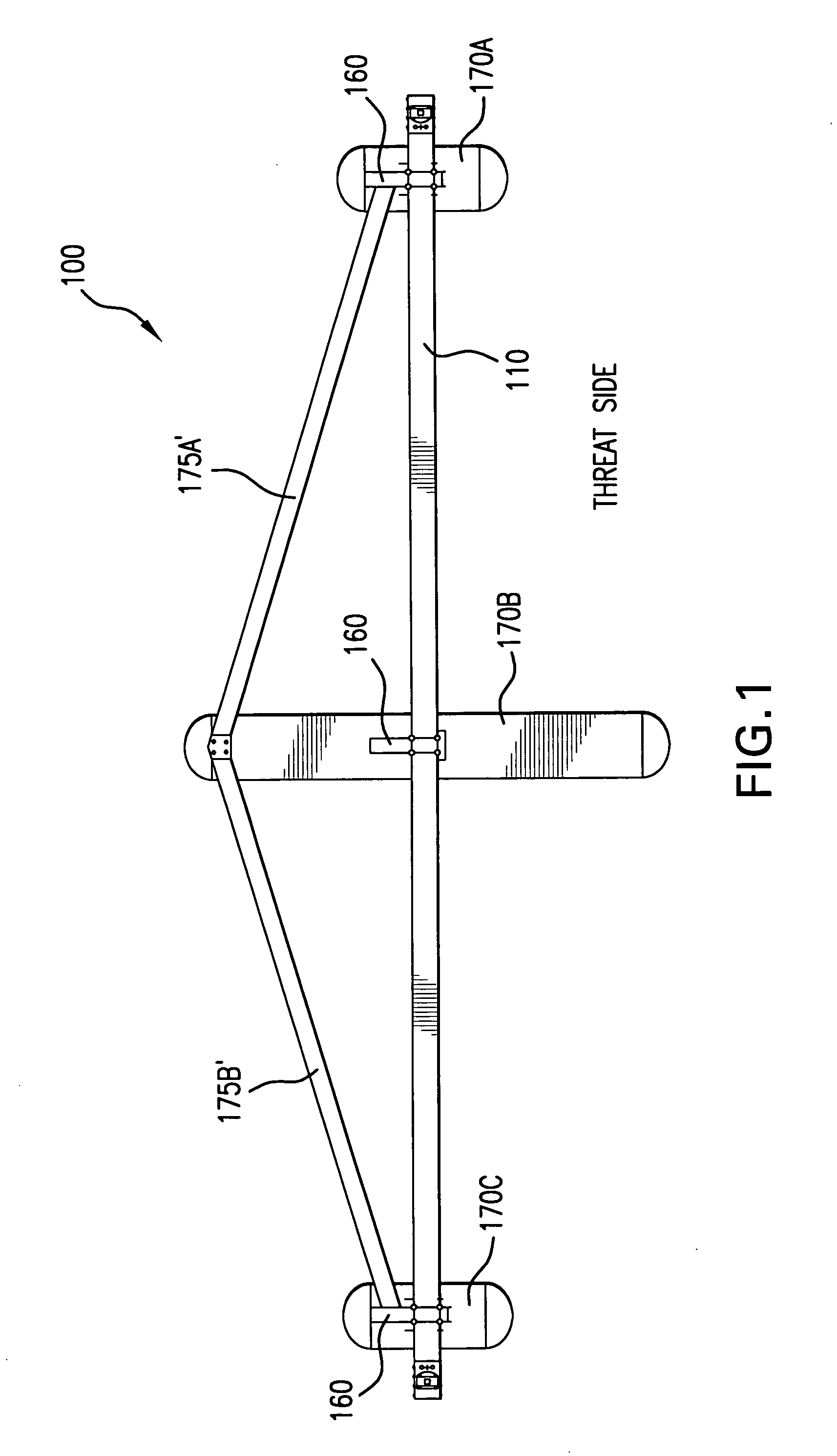

[0024] The HPB is very similar to the HPB as described in U.S. patent application Ser. No. 10 / 621,655, entitled “Protection Barrier Apparatus”, which is assigned to the same assignee as this application, and which is incorporated in its entirety herein by reference.

[0025] The HPB according to the first embodiment is fabricated out of composite materials for practically all of the portion of the protection barrier structure that is disposed above the water line, and it is constructed primarily out of foam materials for the pontoon structure that floats on the water and that provides the structural capability for each HPB protection barrier unit to float on the water. The HPB is designed to have a low life cycle maintenance cost as compared to conventional structures, while at the same time it is designed to provide an acceptable boat stopping capability to protect military and / or commercial harbors or other types of regions that abut a body of water (or to protect a water region or ...

second embodiment

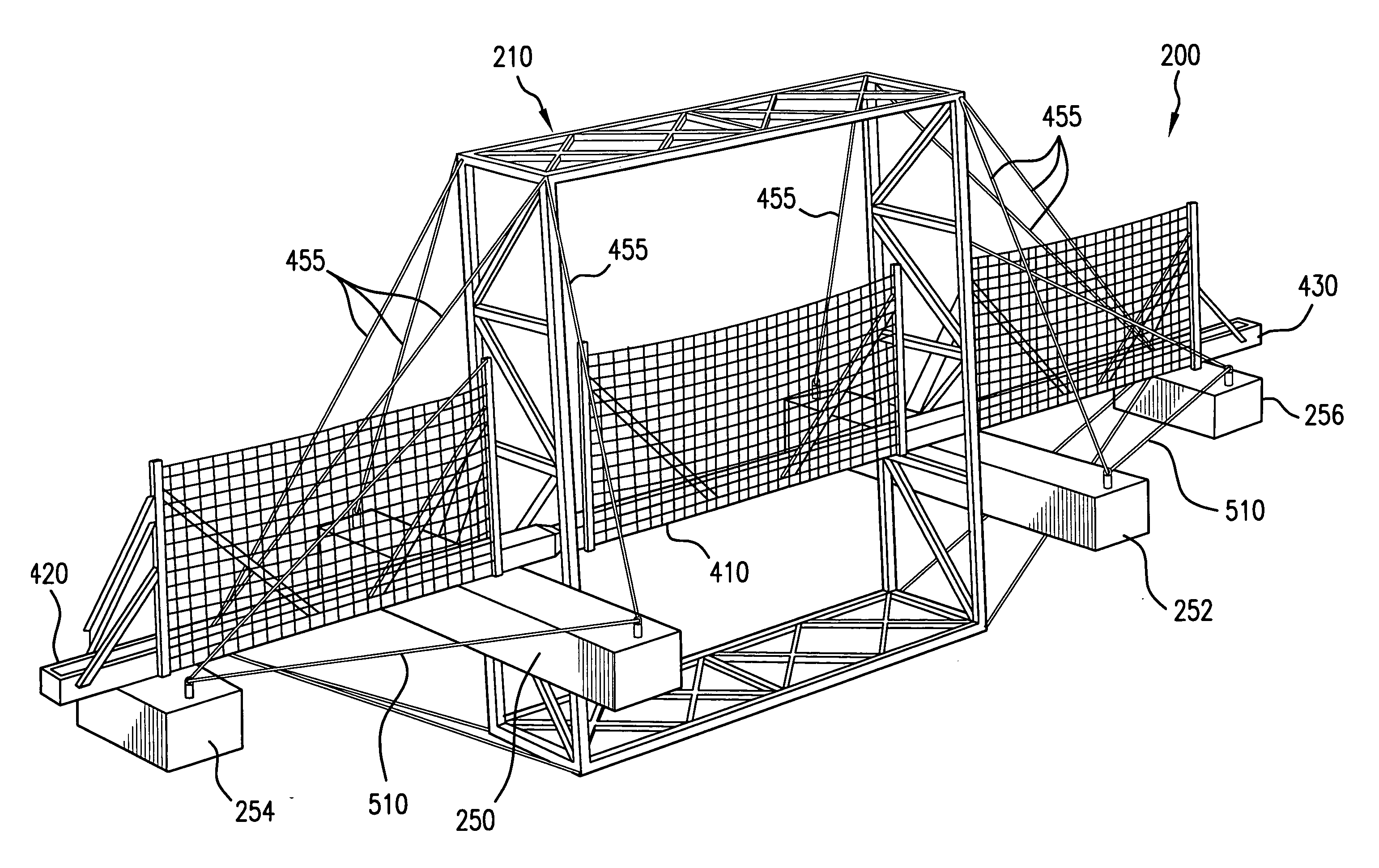

[0029] the invention will be described below with reference to FIGS. 2-6, which show various features of a gate barrier 200 that includes a truss 210. The gate barrier 200 may be utilized with non-gate barriers to provide protection over a large region, whereby the non-gate barriers may be constructed as described above with respect to the first embodiment or as described in the various embodiments provided in the co-pending U.S. patent application Ser. No. 10 / 621,651, or whereby the non-gate barriers may be any conventional harbor protection barrier.

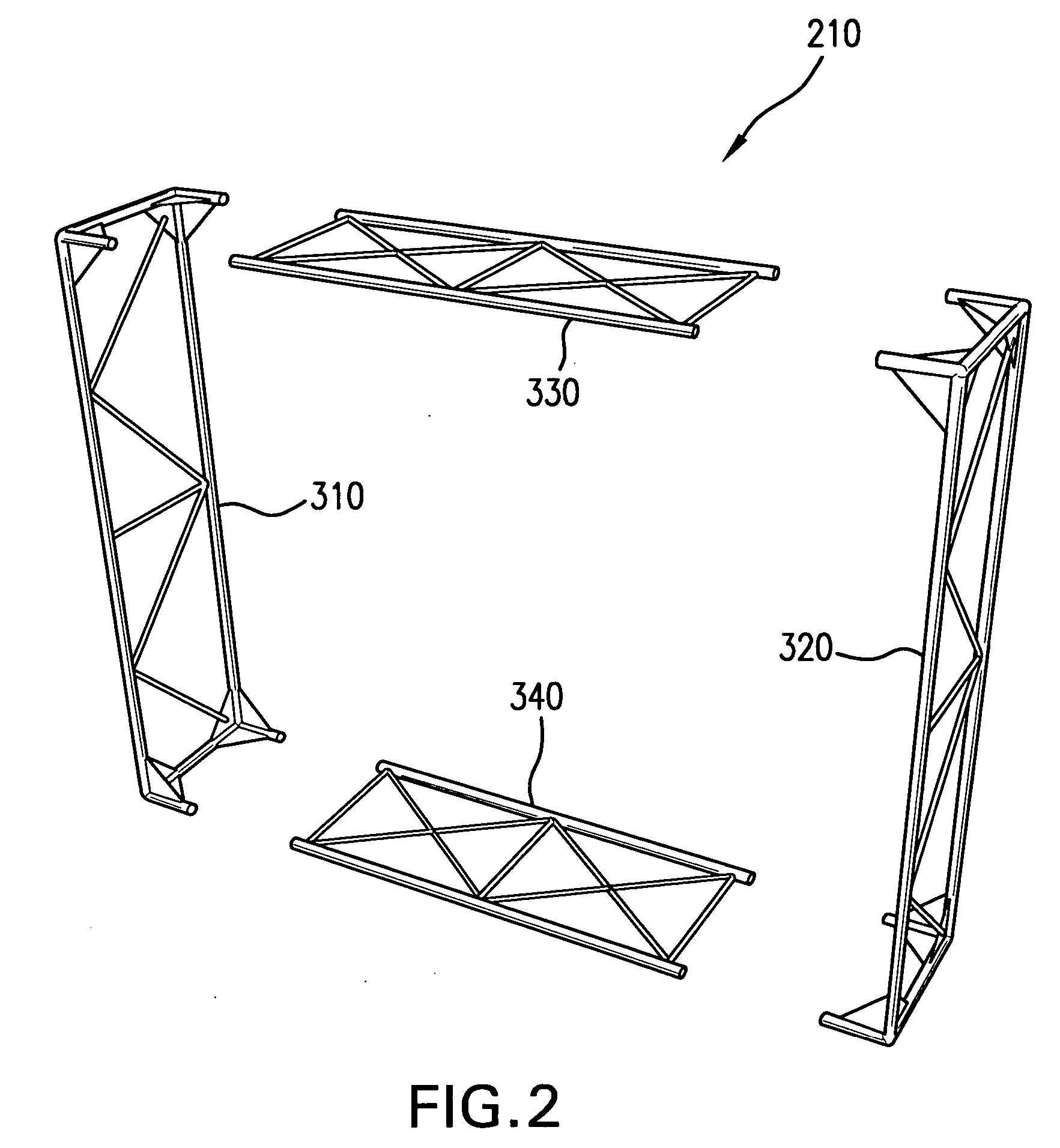

[0030] The gate barrier 200 includes a truss structure 210, as shown in FIGS. 2 and 3. The truss structure 210 includes two vertical truss sections 310, 320 and two horizontal truss sections 330, 340, which are connected together to form a box-like structure (see FIG. 3). The truss sections are preferably made of stainless steel pipe, such as Schedule 40 steel, or carbon steel. Preferably, 3″ Schedule 40 pipes are used for the main trus...

third embodiment

[0051] In a third embodiment, the gate 410 may be configured to open straight upward (vertically) instead of straight across (horizontally), whereby a wire rope / pulley mechanism that is coupled to the gate and to the top horizontal portion 330 of the truss 210 may be utilized to achieve such movement of the gate 410.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com