Collateral Cavity Electromagnetic Propulsion Guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

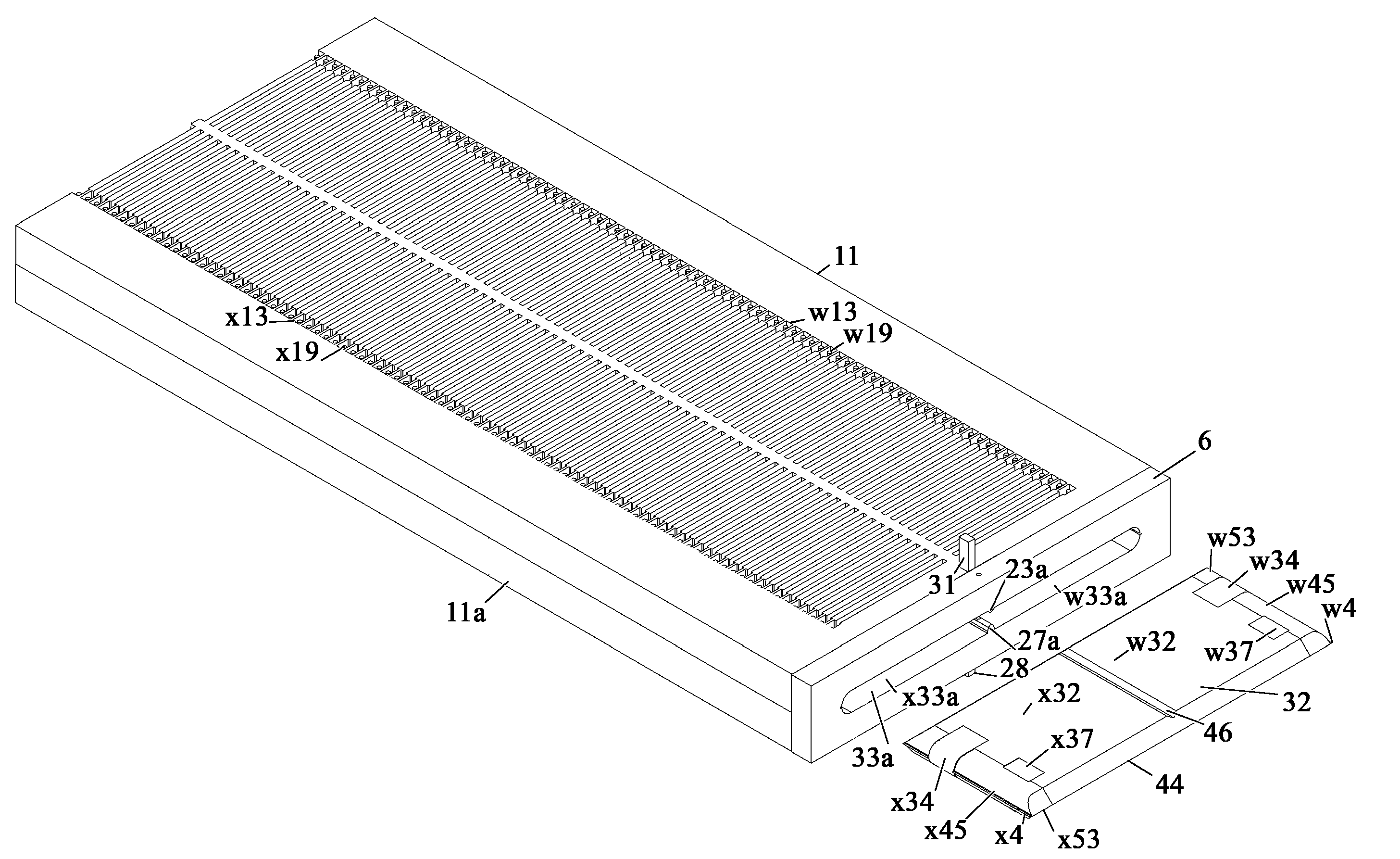

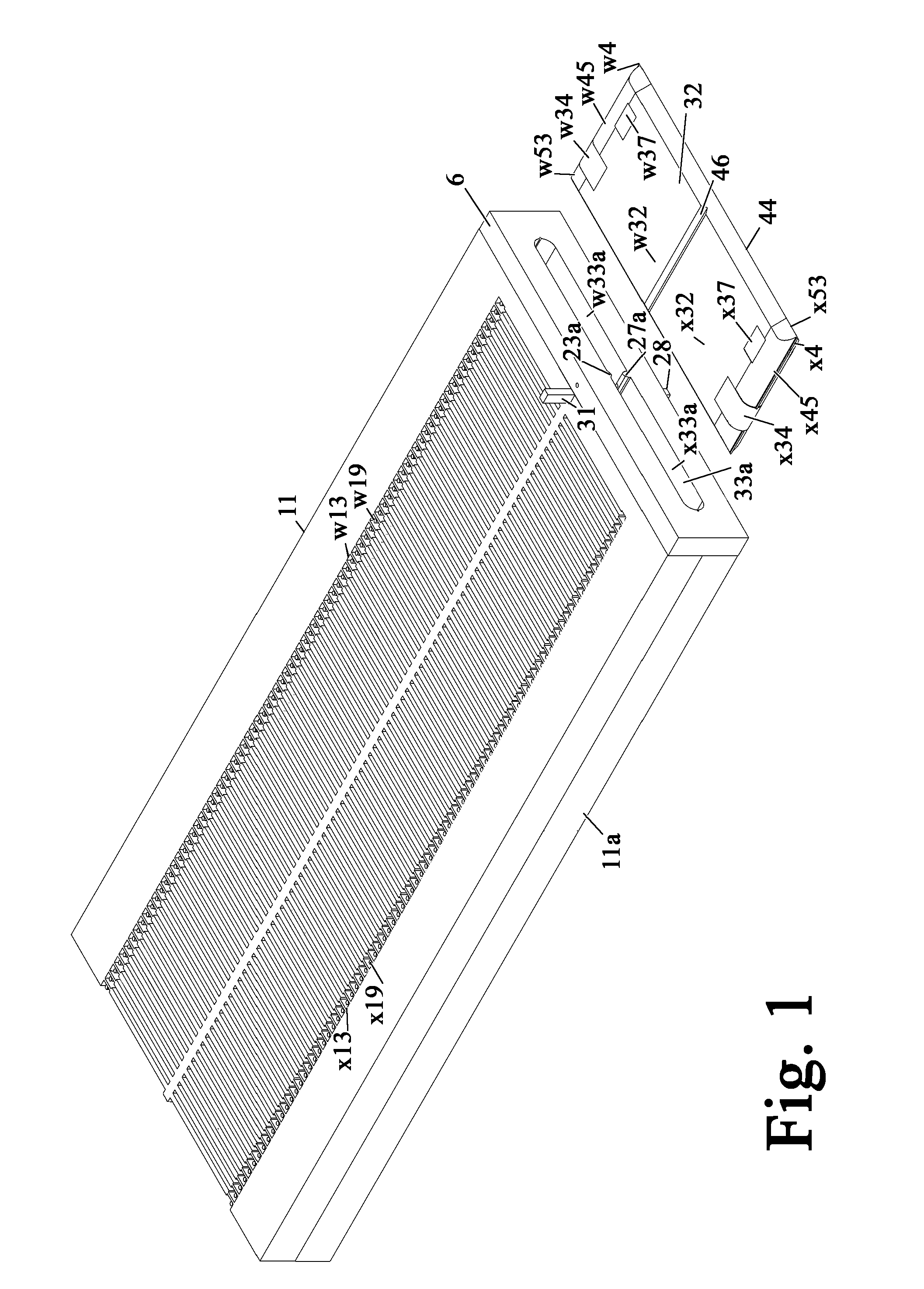

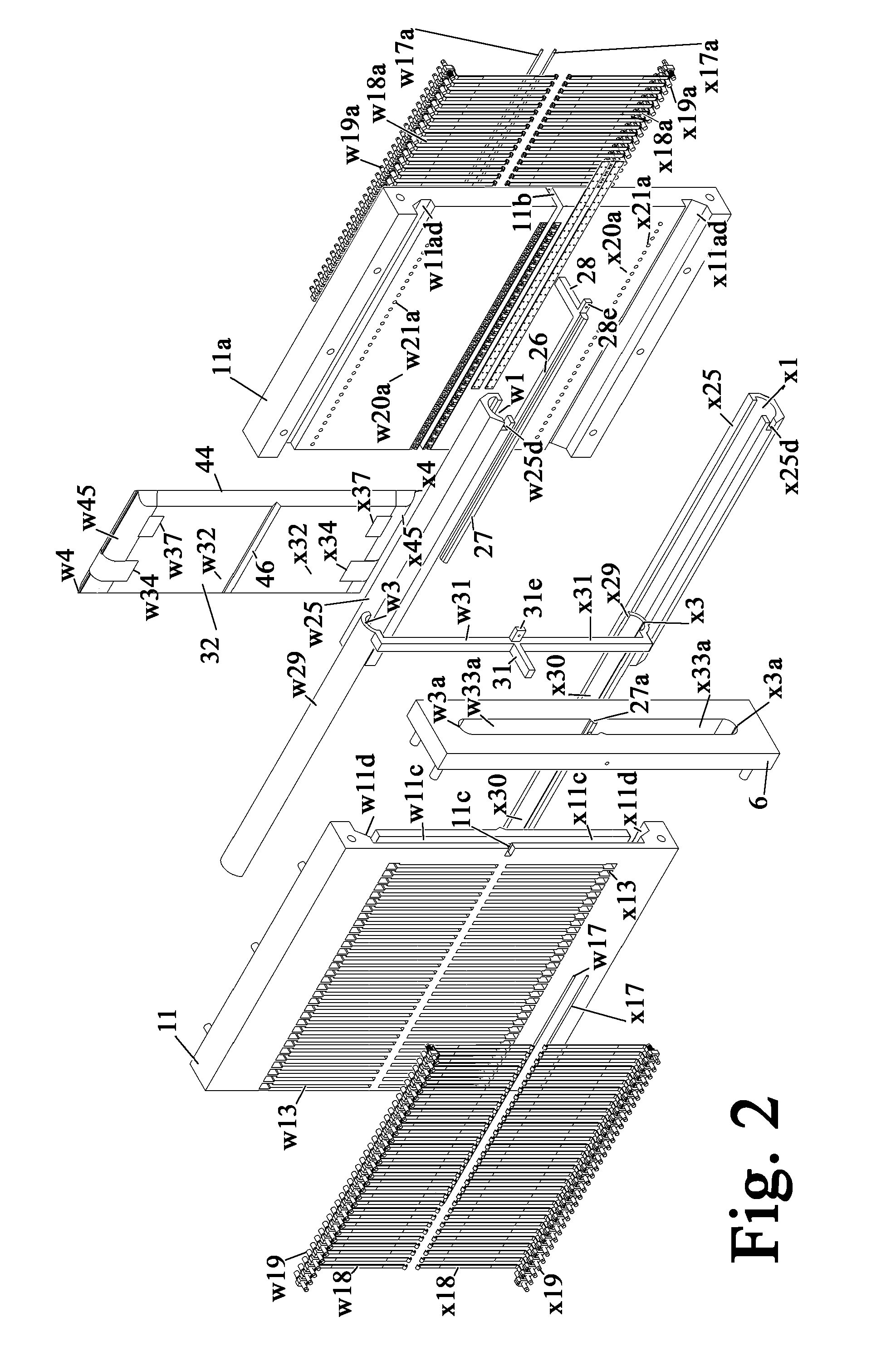

[0028] Devices of this invention are electromagnetic propulsion guns that have a barrel with a narrow cavity, the barrel cavity, extending there through. The barrel cavity has a breech end opening at one barrel end and a muzzle end opening at the other barrel end and a central axis extending said cavity's length which is parallel to the cavity's surfaces.

[0029] Disregarding slight variations in the cavity's profiles in barrel cavity right sections taken at the openings in the barrel cavity walls for wall conductor's contact means and said means therein, right sections taken to the central cavity axis throughout the cavity are alike; i.e. cavity's profiles in right section planes to said cavity axis are alike.

[0030] The cavity's central axis is through the centroid centers of the cavity's profile in said right sections. Generally the central axis of an element is the line through the centroid centers of right sections taken through said element along a path in which said element's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com