Foldable pawl and ratchet assembly

a technology of ratchet and pawl, which is applied in the field of folding pawl and ratchet assembly of furniture, can solve the problems of increased manufacturing time and cost of furniture, ratcheting or clicking noise, and the pawl arm and locking tip may not provide the optimum angle for engagement, so as to reduce sliding contact friction, reduce manufacturing time and cost, and facilitate disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description of some preferred aspects of the present invention is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

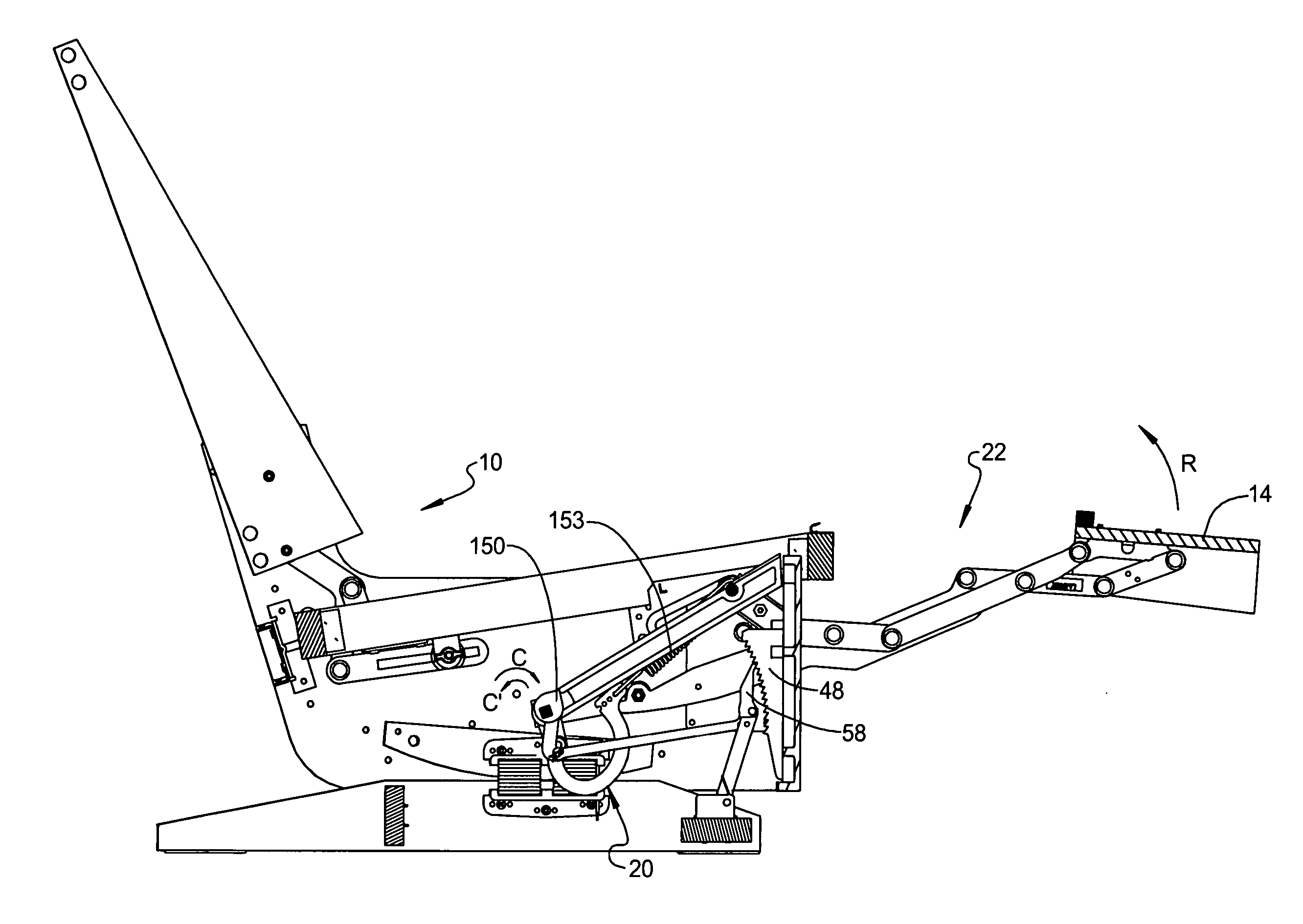

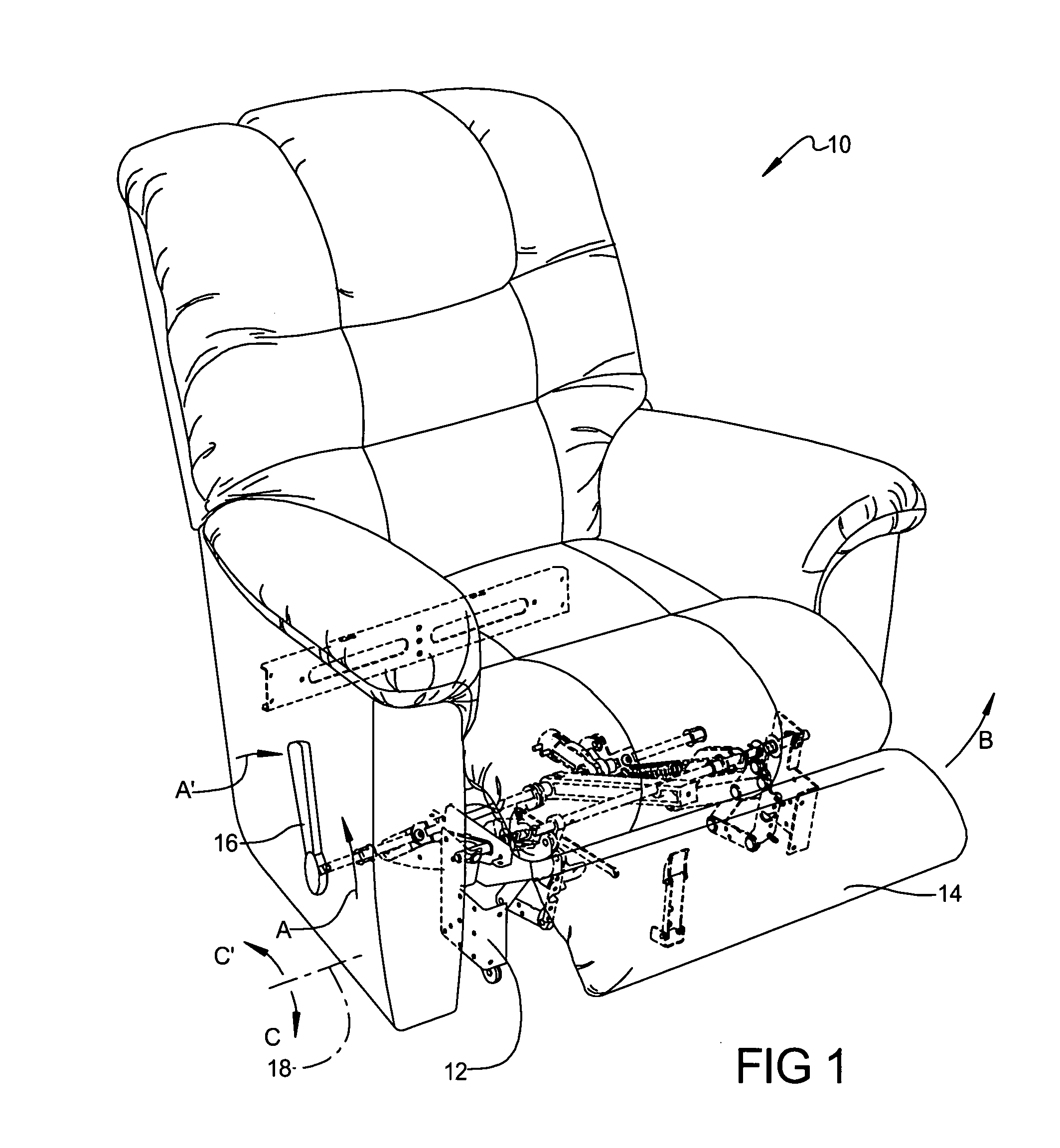

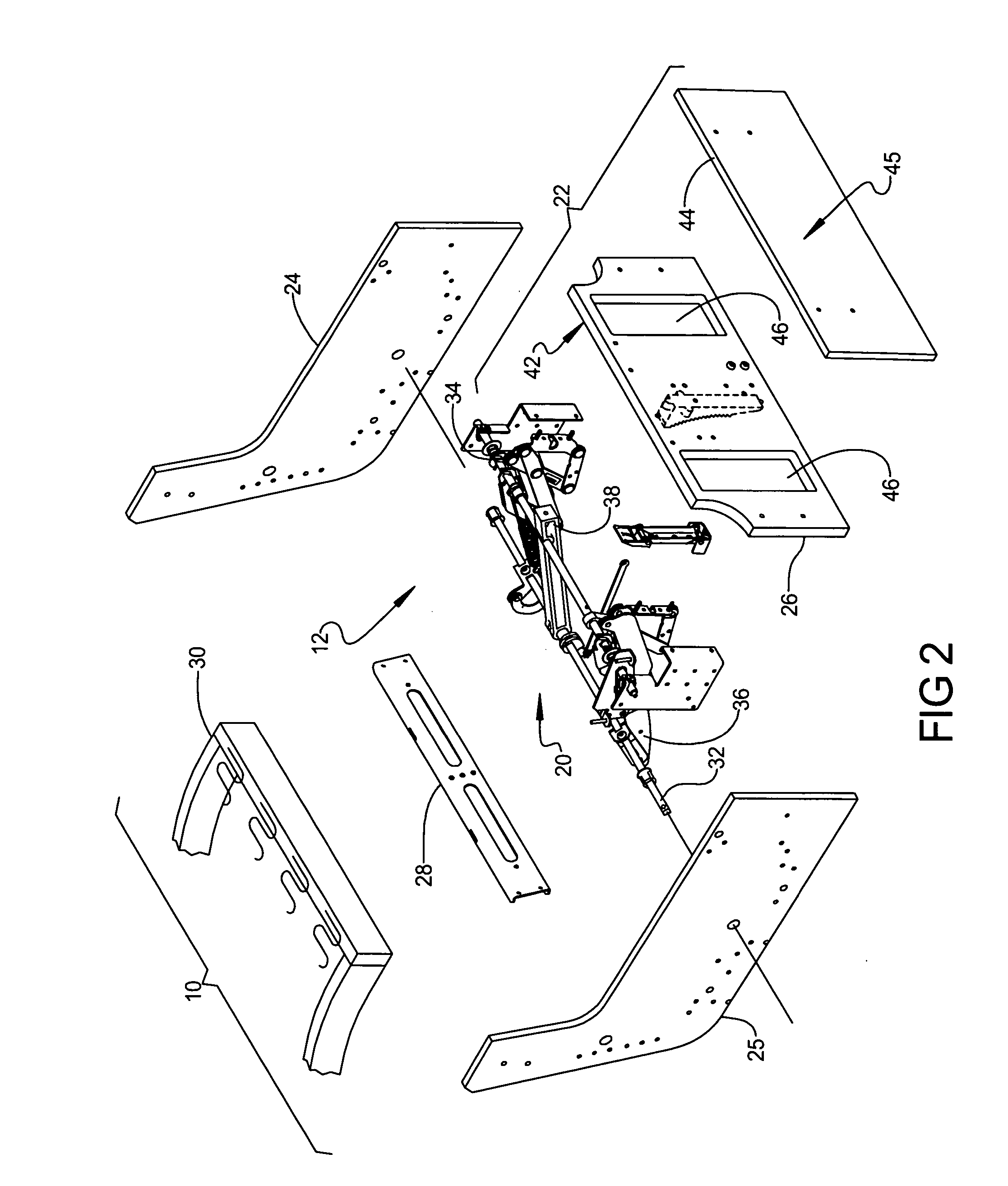

[0034] With particular reference now to the drawings, in accordance with the teachings of the present invention and referring generally to FIG. 1, a furniture member 10 such as a rocking, reclining chair includes an actuation mechanism 12 for use in single or multi-person furniture members 10. In the aspect shown, furniture member 10 is a chair, however, the invention is not limited to chairs. Furniture member 10 can be any of a plurality of furniture members, including, but not limited to chairs, sofas and / or loveseats. Furniture member 10 and actuation mechanism 12 in the Figures herein are further shown representing a rocking configuration. Actuation mechanism 12 controls the position of a leg rest 14 between a stowed position (shown in phantom) and an extended position (partially shown) by op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com