Screed joints

a screw and groove technology, applied in the field of screw joints, can solve the problems of affecting the smoothness the ill-suited application of the prior weep screed arrangement, and the inability to accommodate the movement of the weep screed between the walls, and achieve the effect of facilitating flexible movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

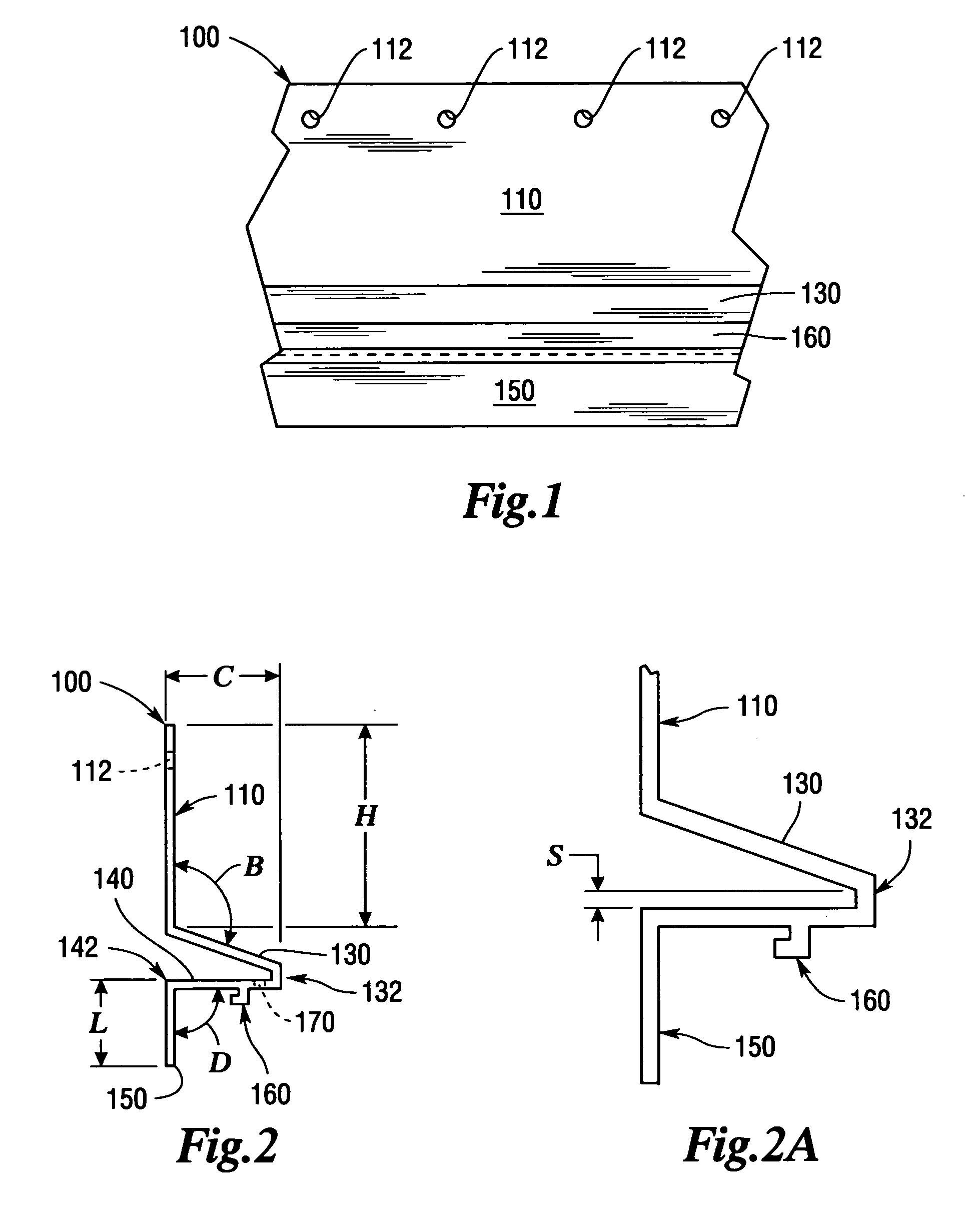

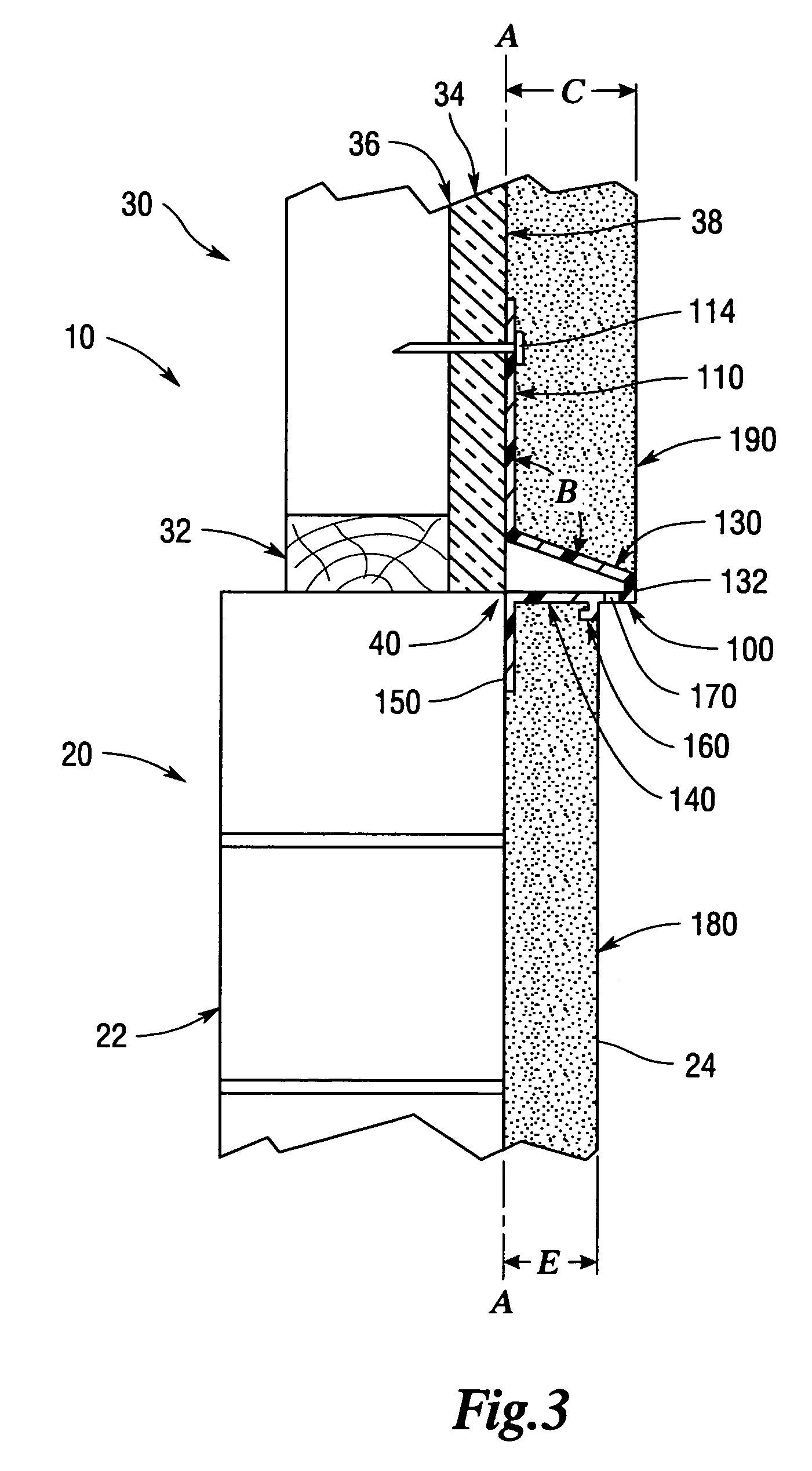

[0023] Referring now to the drawings for the purposes of illustrating the present embodiments of the invention only and not for the purposes of limiting the same, FIGS. 1-3 illustrate one embodiment of a screed joint 100 of the present invention used in connection with the application of plaster, stucco, etc. to the wall surfaces of a building. As used herein, the term “plaster” encompasses not only commercially available wall plaster materials, cement and stucco materials, but also essentially any materials that are flowable in an uncured state and which solidify in a cured state. Also, the terms “first story” and “second story” and “first wall” and “second wall” have been used herein in an exemplary manner to described one use of various embodiments of the subject invention. Such terms should in no way be deemed as limiting use of various embodiments to use solely between first and second story walls. Various embodiments of the present invention could be effectively used between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com