Product display and fronting assembly

a product display and fronting technology, applied in the field of systems and methods for displaying and dispensing products, can solve the problems of cumbersome or awkward access to merchandise at the rear of the shelves or pallets, lack of products on the front of the shelves, and unattractive to consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

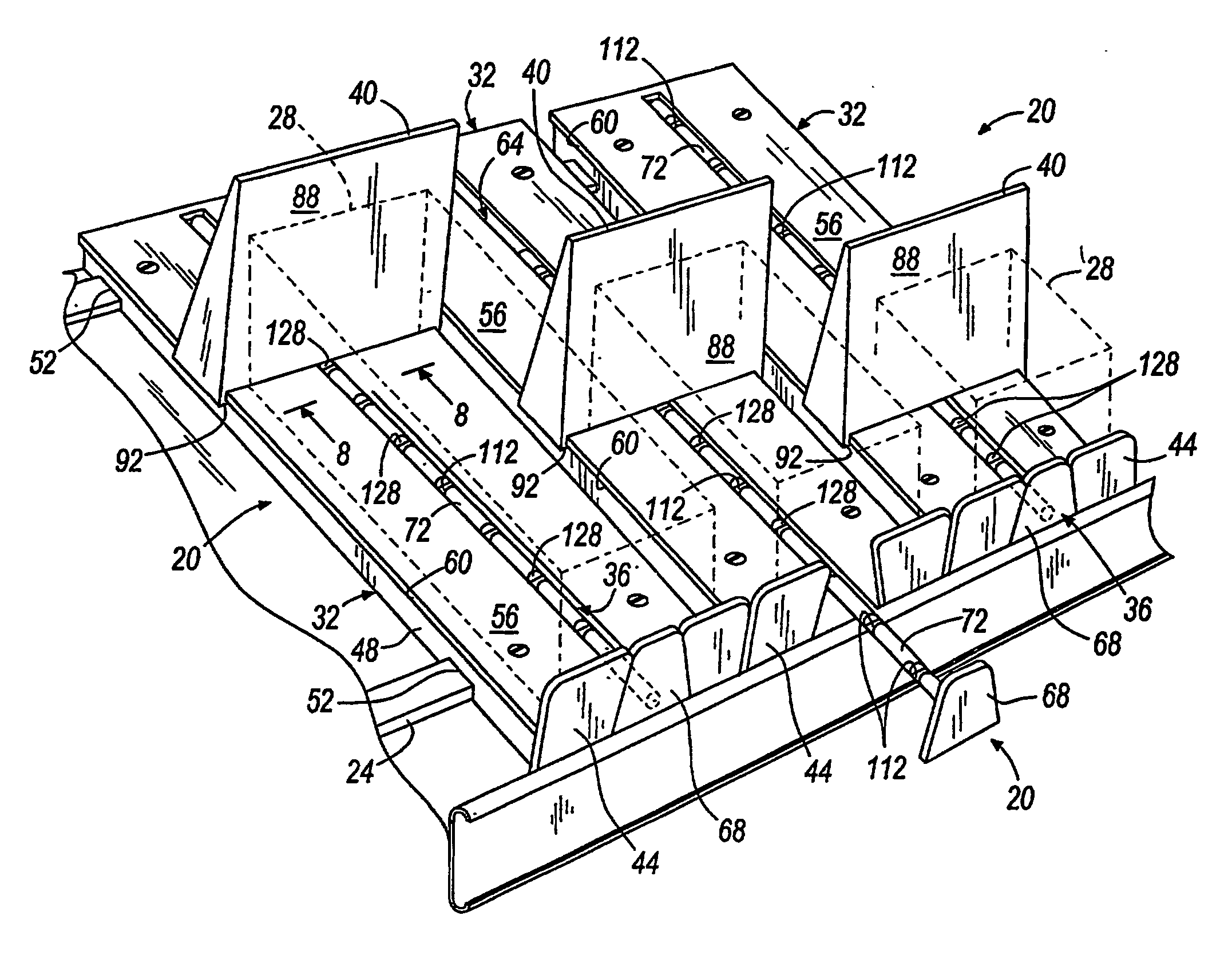

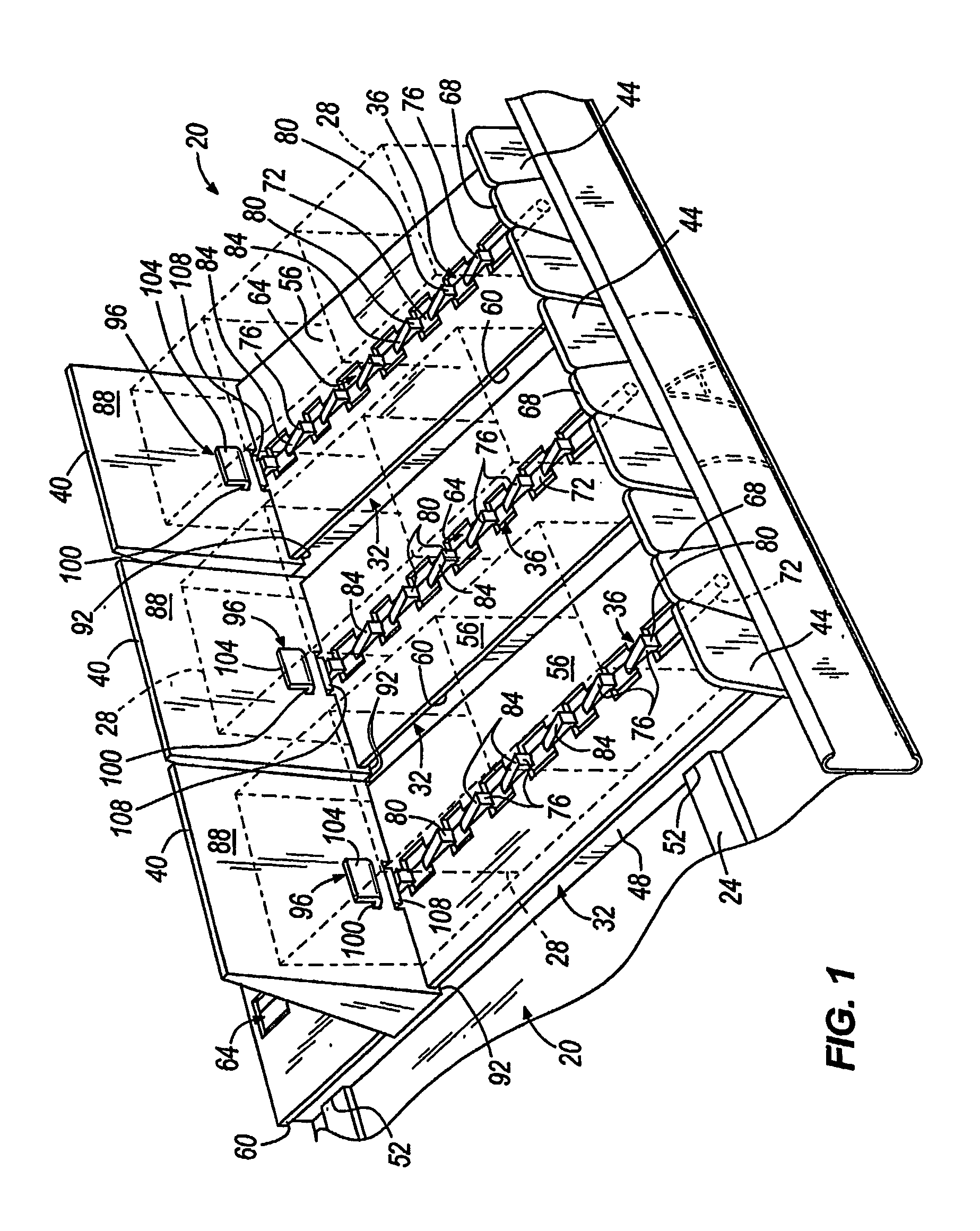

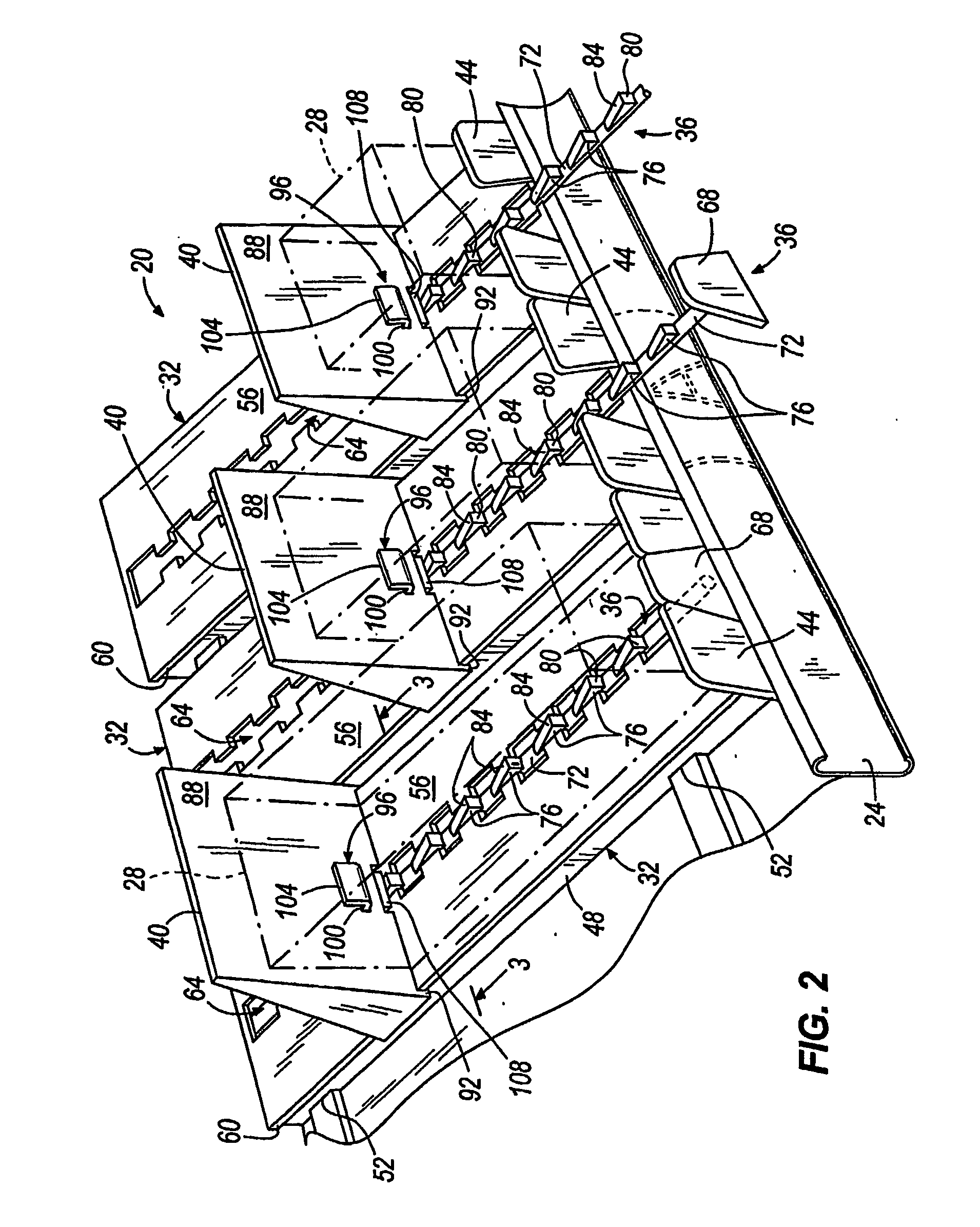

[0076]FIGS. 1-6 show a product display and fronting assembly 20 according to an exemplary embodiment of the present invention. The assembly 20 illustrated in FIGS. 1-6 is adapted for installation on a steel shelf 24 by way of example only. Although a steel shelf-based assembly is shown, the present invention can be employed with any other product storage or display device or assembly used to store and / or display products 28 (e.g., pallets, racks, and the like). Although the shelf 24 is made of steel in the assembly shown, the shelf 24 can be made of materials other than steel, such as iron, stainless steel, or any other metal, plastic, wood, composite material, and the like. In some embodiments of the present invention, the assembly 20 is utilized without a shelf or other product storage or display device and supports the product 28 by itself.

[0077] The assembly 20 is used to move products 28 stored the shelf 24 forward (such as to fill empty spaces at the front of the shelf, to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com