Wafer guide in wafer cleaning apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

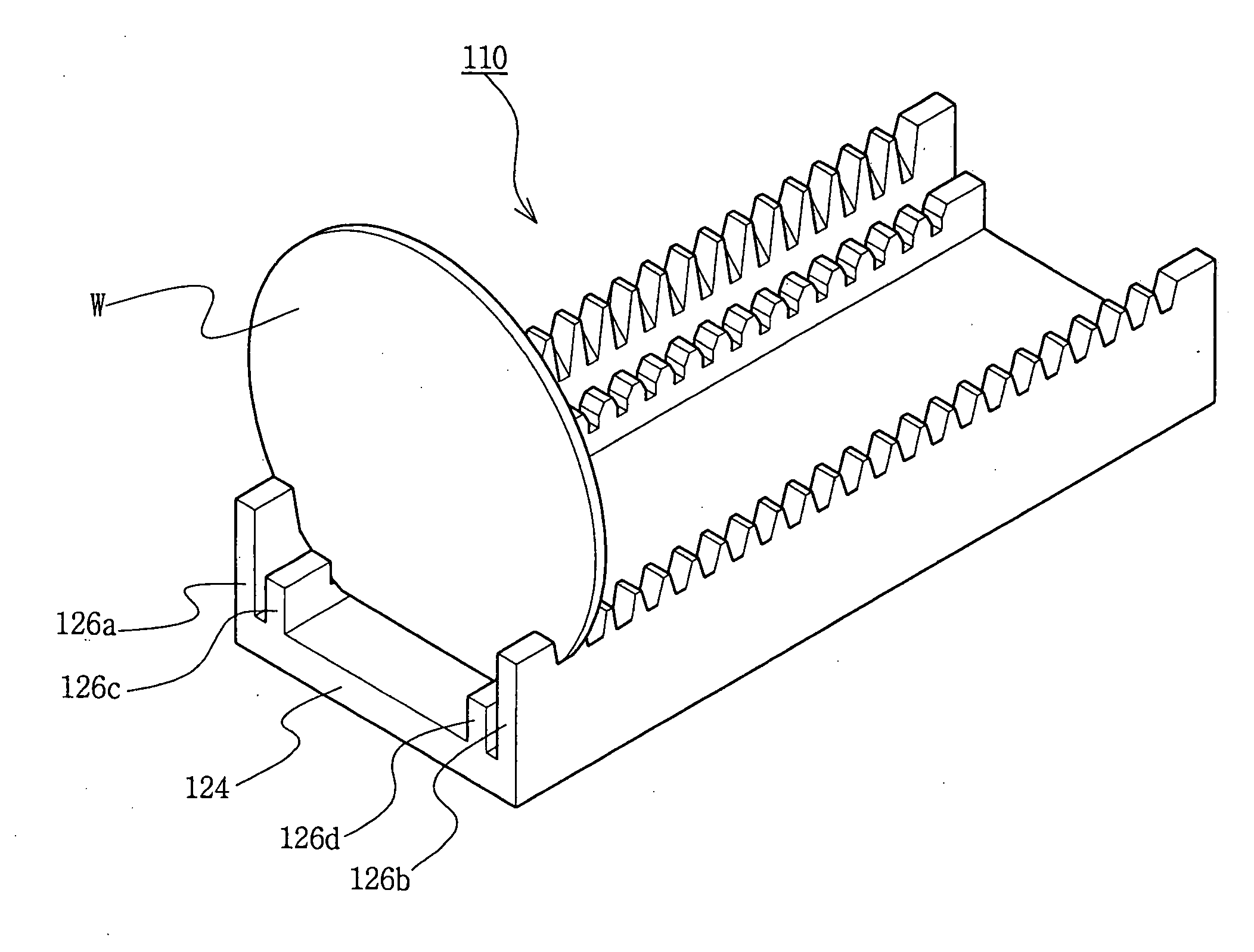

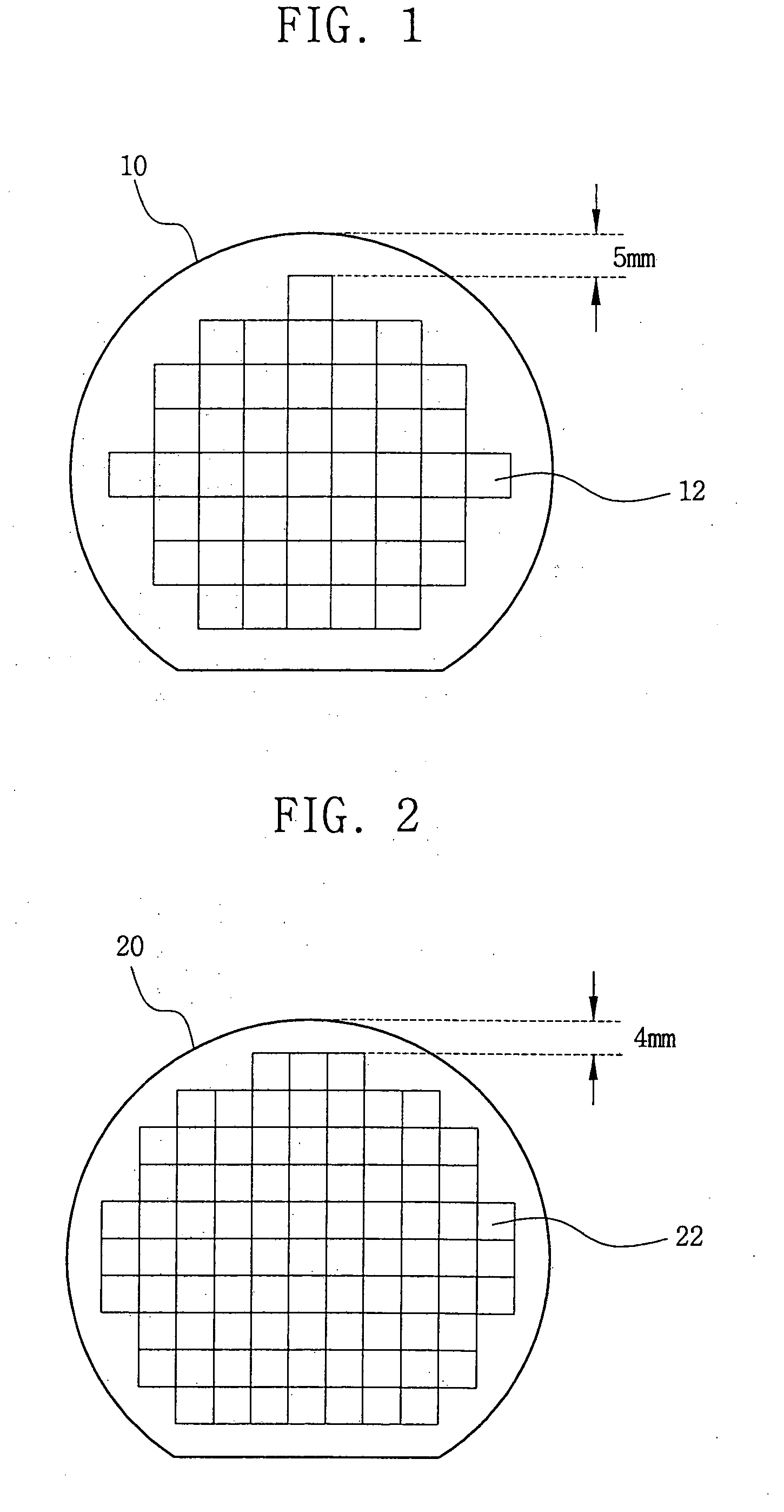

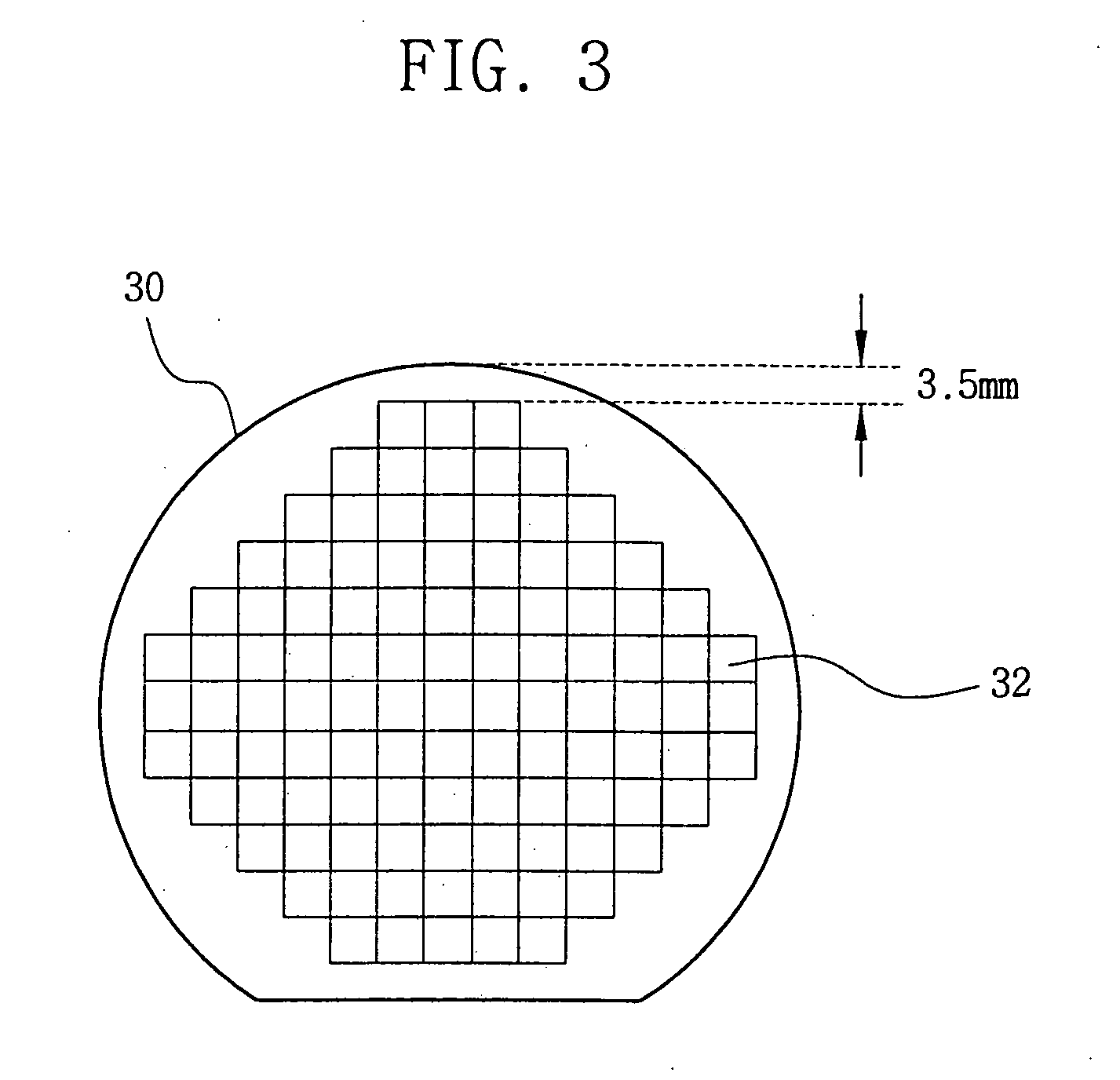

[0031] The present invention will now be described with reference to the accompanying drawings, in which preferred embodiments of the invention are shown. However, the invention should not be construed as limited to only the embodiments set forth herein. Rather, the present invention may be embodied in many different forms, and the embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0032] Various unit processes such as, for example, an ion implantation process, deposition process, and etching process, are performed on a wafer during a semiconductor fabrication process. These unit processes also generate contaminants. These contaminants may include material layers such as a photosensitive layer that is not removed properly during an etching process, or reaction byproducts such as polymers. Furthermore, these polymers adhere to the surface of a semiconductor wafer and may cause v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com