Security mesh panel

a mesh panel and security technology, applied in the field of security panels, can solve the problems of inconvenient use, high cost of materials for many applications, and weak joints in each join, so as to improve the overall strength of the security panel and improve the security of the panel. , the effect of strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

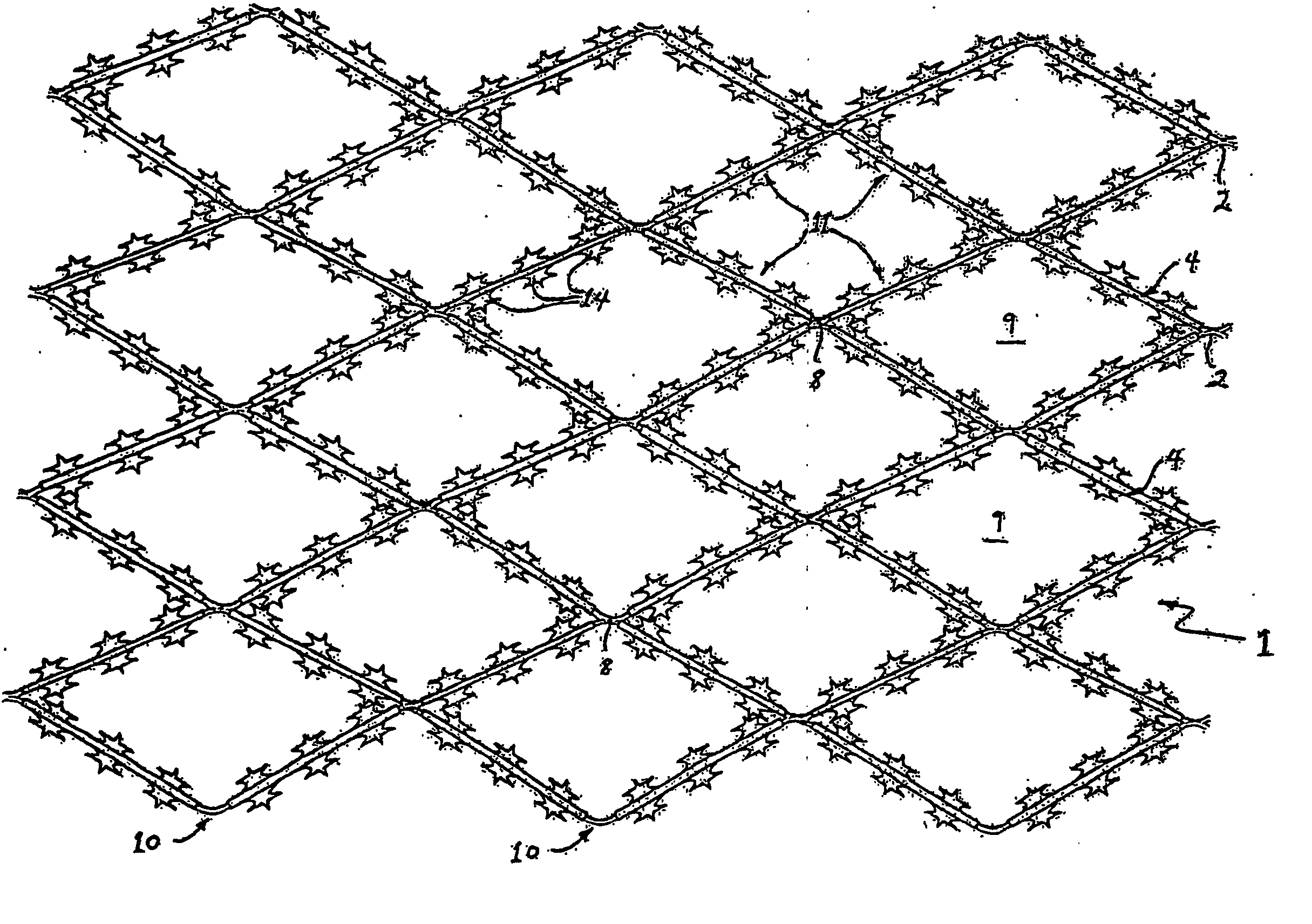

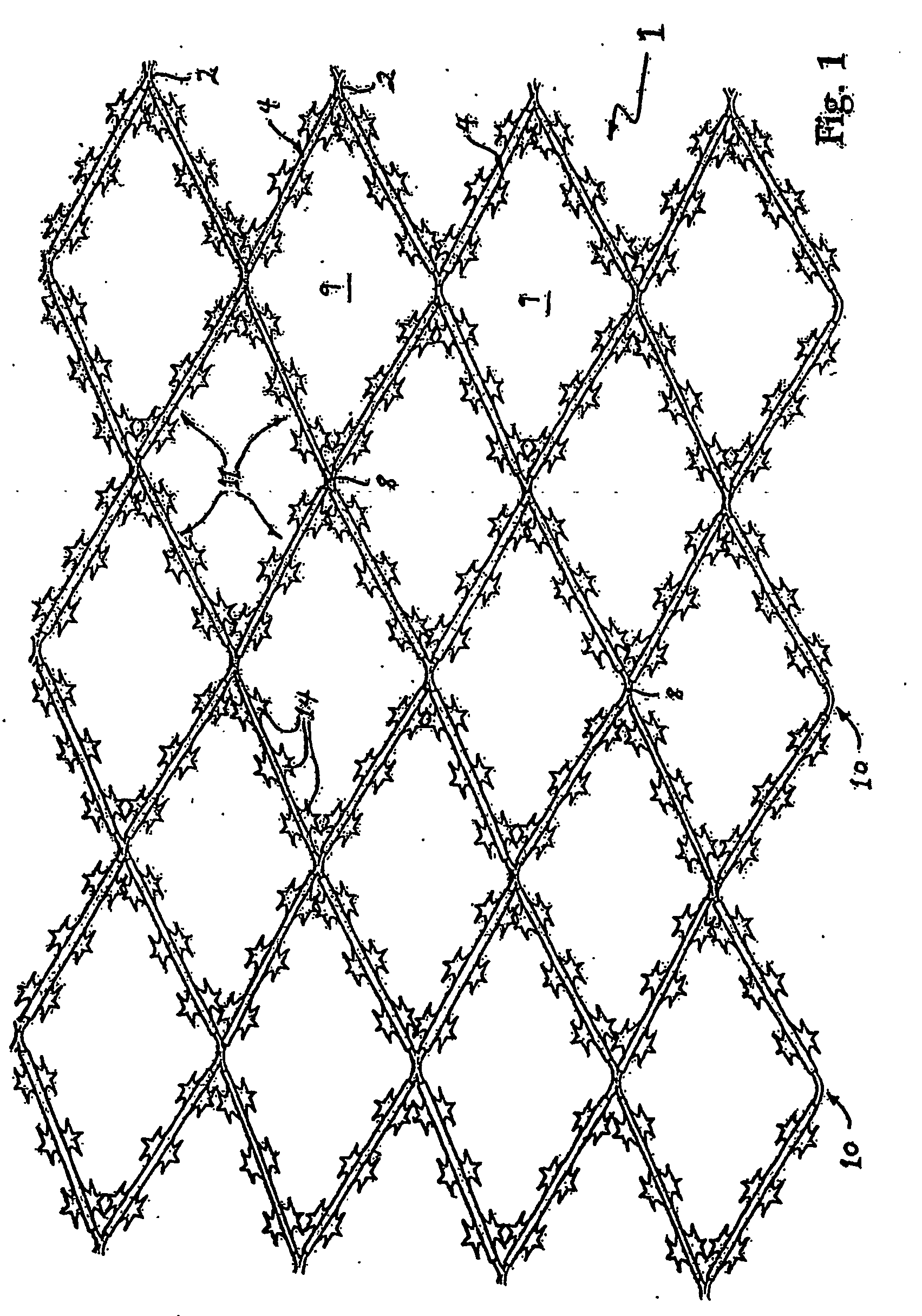

[0023]FIG. 1 shows a plan view of one side of a security mesh panel 1. The security panel 1 is formed from a planar expanded metal mesh 2 to which individual elongate metal barbed structures 4 have been permanently affixed, for example by spot welding. The expanded mesh 2 is itself formed in a conventional manner from a metal sheet, for example 3 mm thick mild steel, galvanized steel or even stainless steel, through which a series of parallel non-overlapping slits have been punched. After the slits have been formed, a pair of opposite edges of the sheet is pulled apart to expand the sheet and form the mesh 2. If the expanded metal sheet requires corrosion protection, then it may be galvanized.

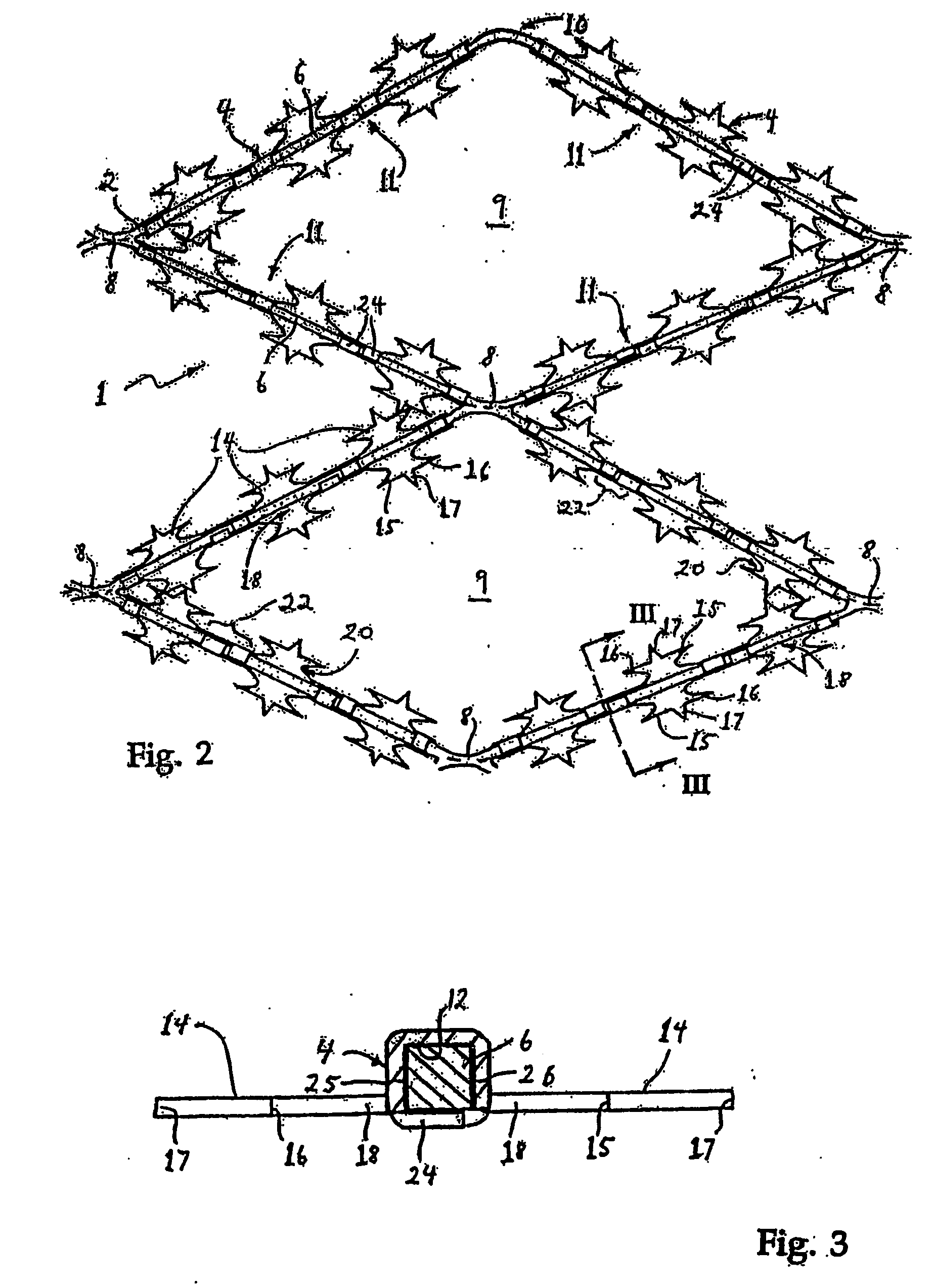

[0024] Reference is now made also to FIGS. 2 and 3, which show respectively an enlarged plan view of a side of the security mesh 2 opposite to that shown in FIG. 1, and a cross section view through the security mesh. The mesh 2 consists of a series of adjacent strips of metal 6, which in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com