Systems and methods for installation of clamshell devices around an element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

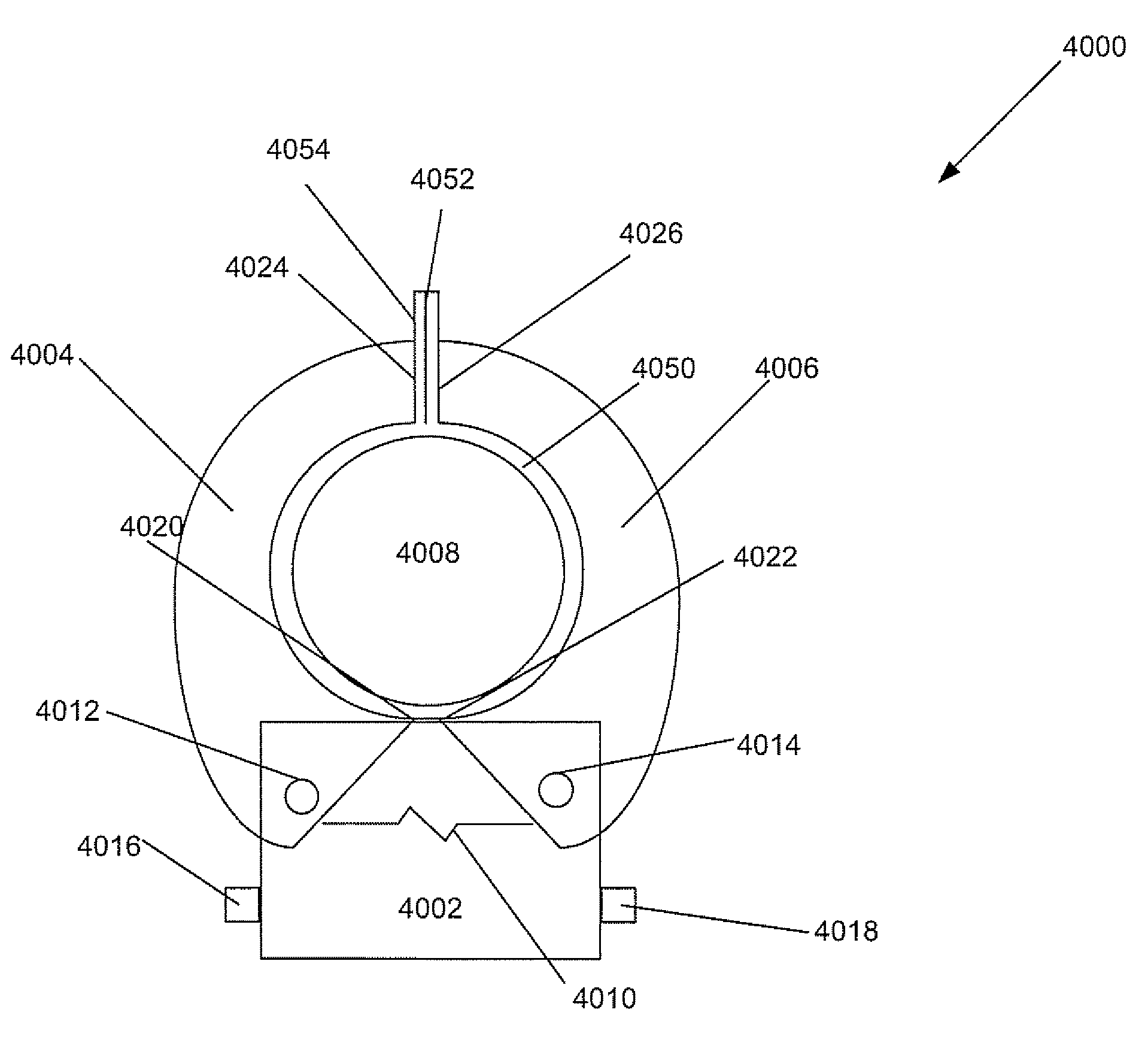

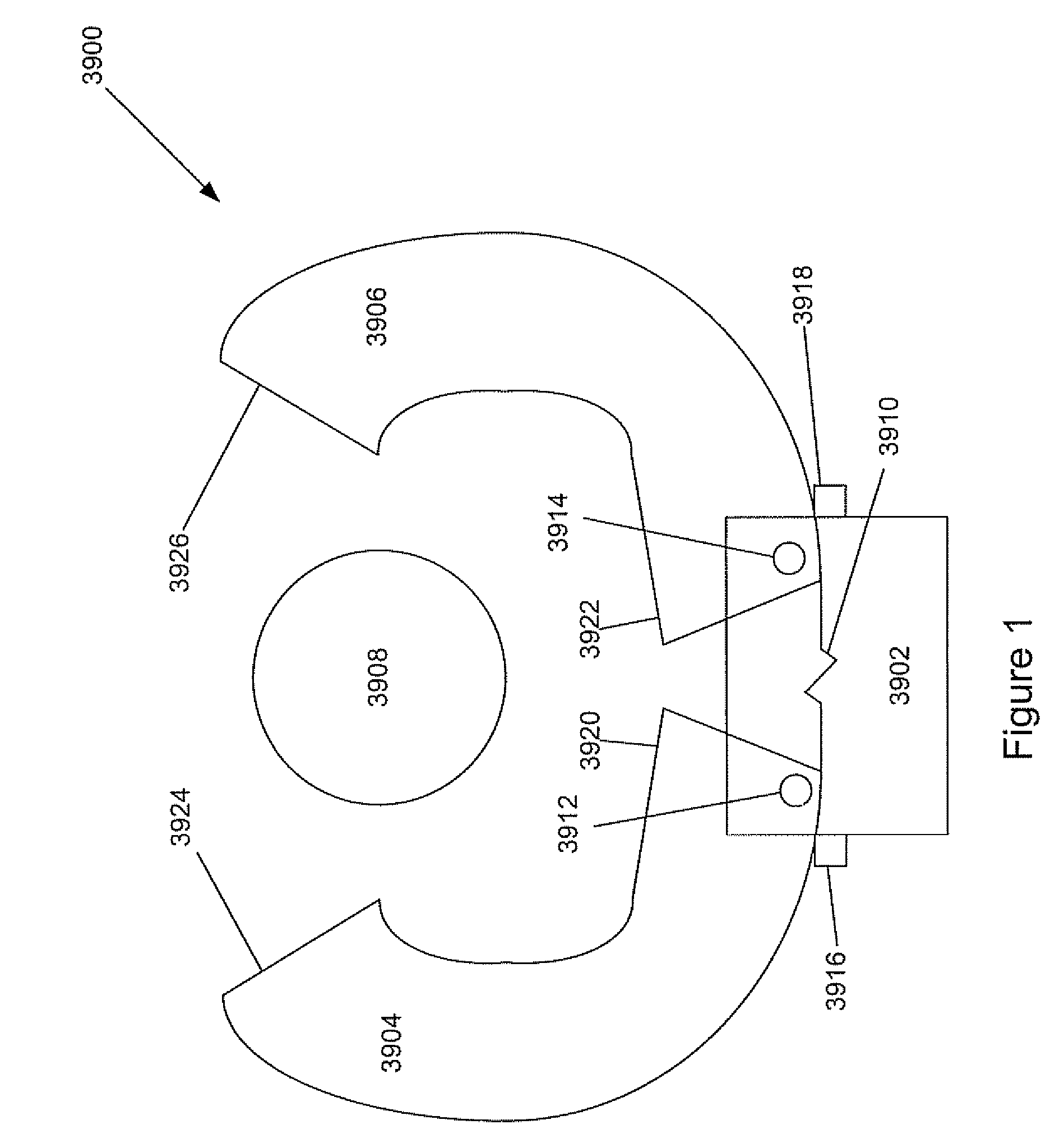

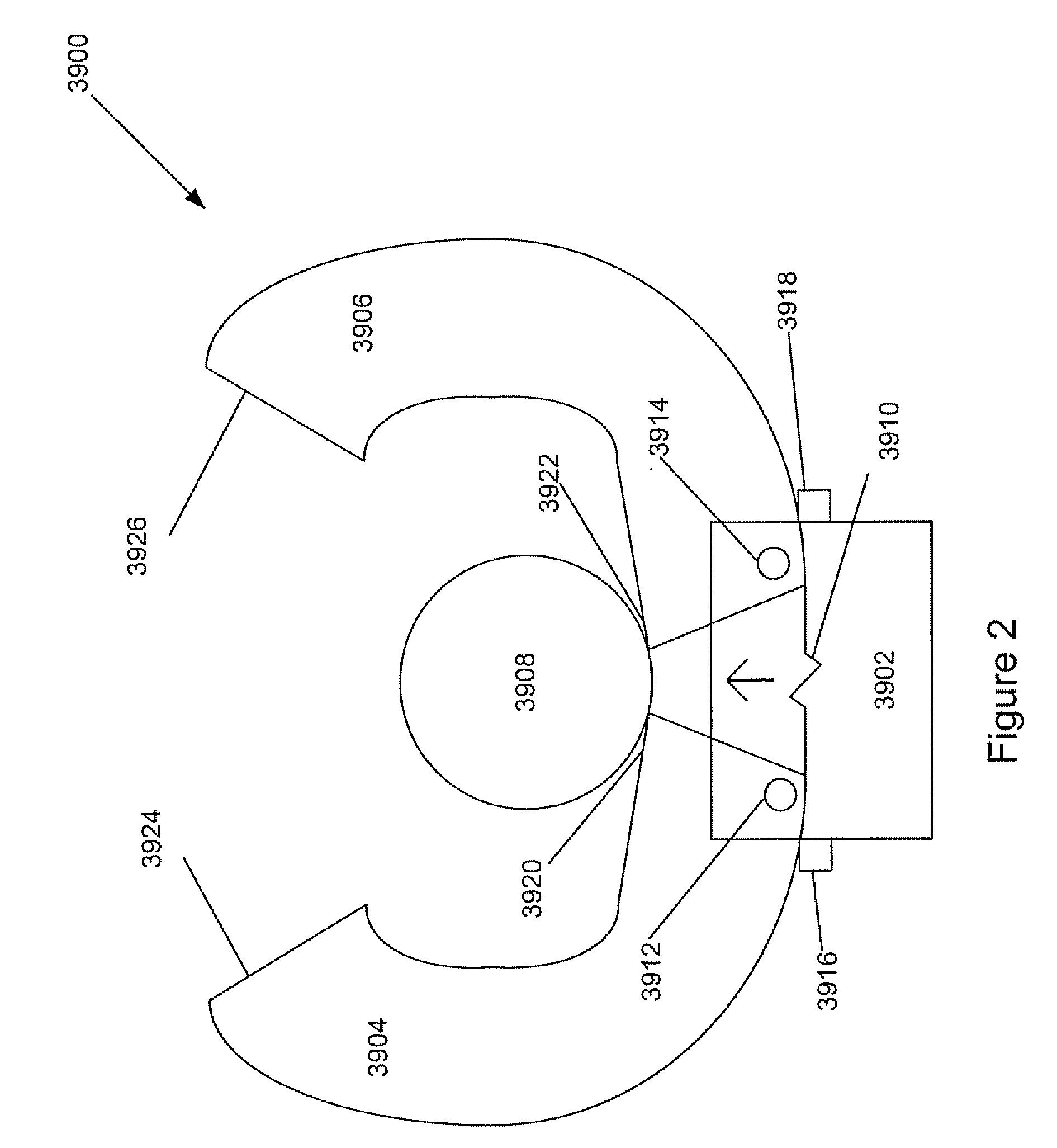

[0035] In one embodiment, there is disclosed a clamp system for remotely installing a clamshell device around an element, the clamp system comprising a body; and at least one set of clamps supported by the body, the set suitable for holding and releasing the clamshell device selected from the group consisting of vortex-induced vibration reduction devices and drag reduction devices, wherein at least one clamp comprises a cam surface adapted to engage the element and close the clamp about the element. In some embodiments, the at least one set of clamps comprises a first clamp comprising a first cam surface, and a second clamp comprising a second cam surface. In some embodiments, the body has a top and a bottom, wherein the at least one set of clamps is comprised of a first set of clamps and a second set of clamps, wherein the first set of clamps is supported by the top of the body and the second set of clamps is supported by the bottom of the body. In some embodiments, there are at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com