Operating apparatus for a working industrial vehicle

a technology for operating apparatuses and industrial vehicles, applied in the direction of electric propulsion mounting, battery/cell propulsion, transportation and packaging, etc., can solve the problem of inability to drive the engine by the generator motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

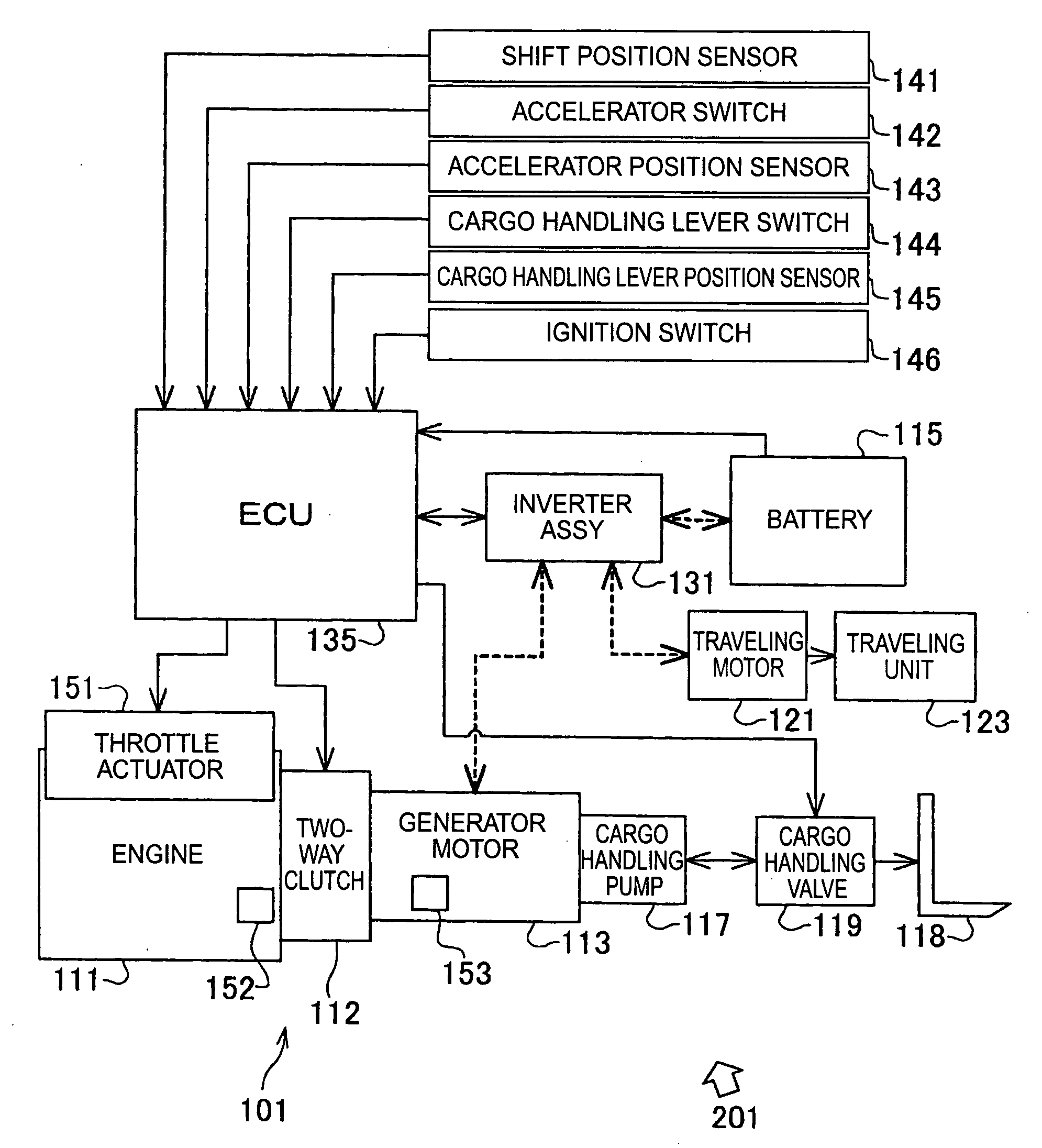

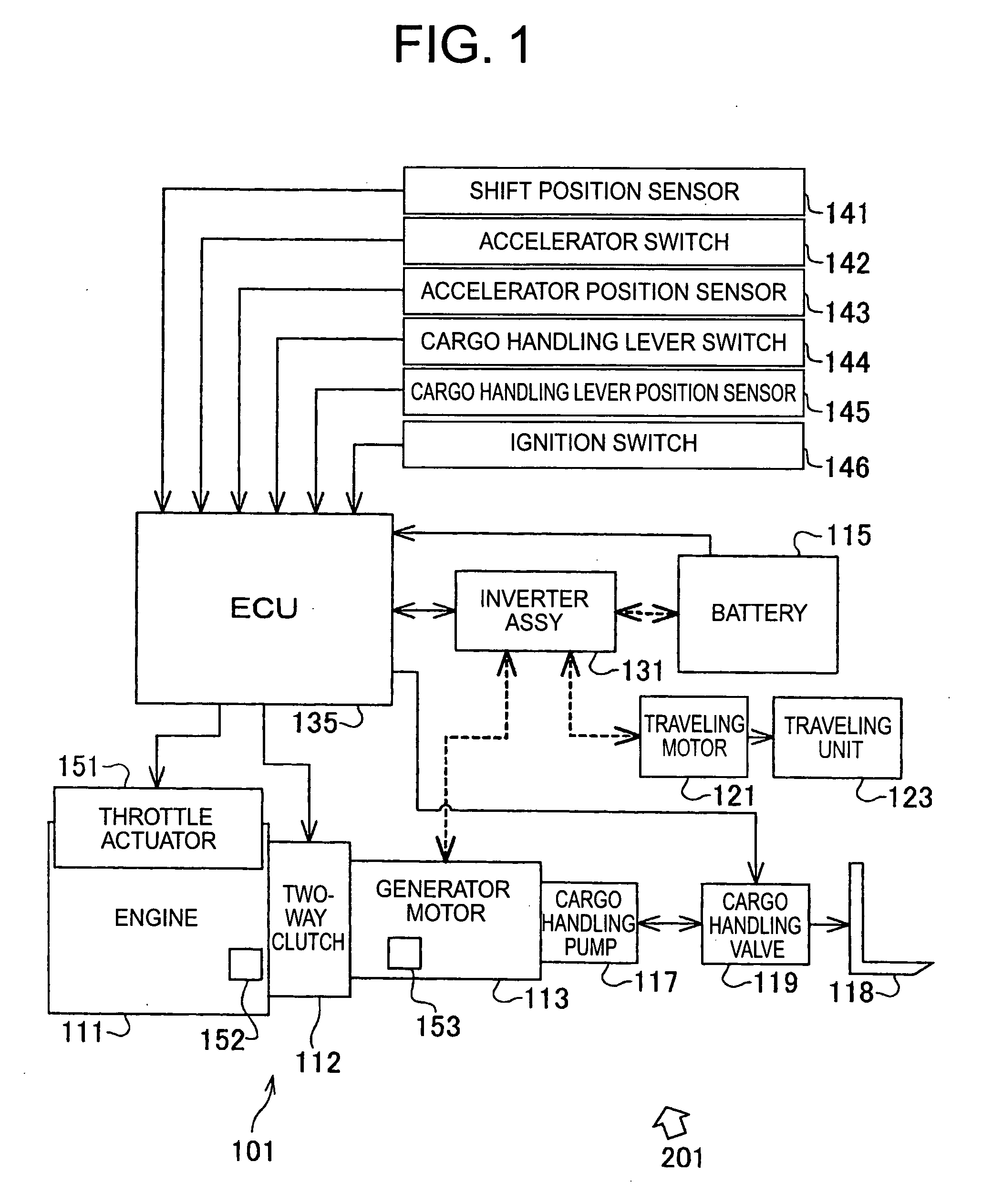

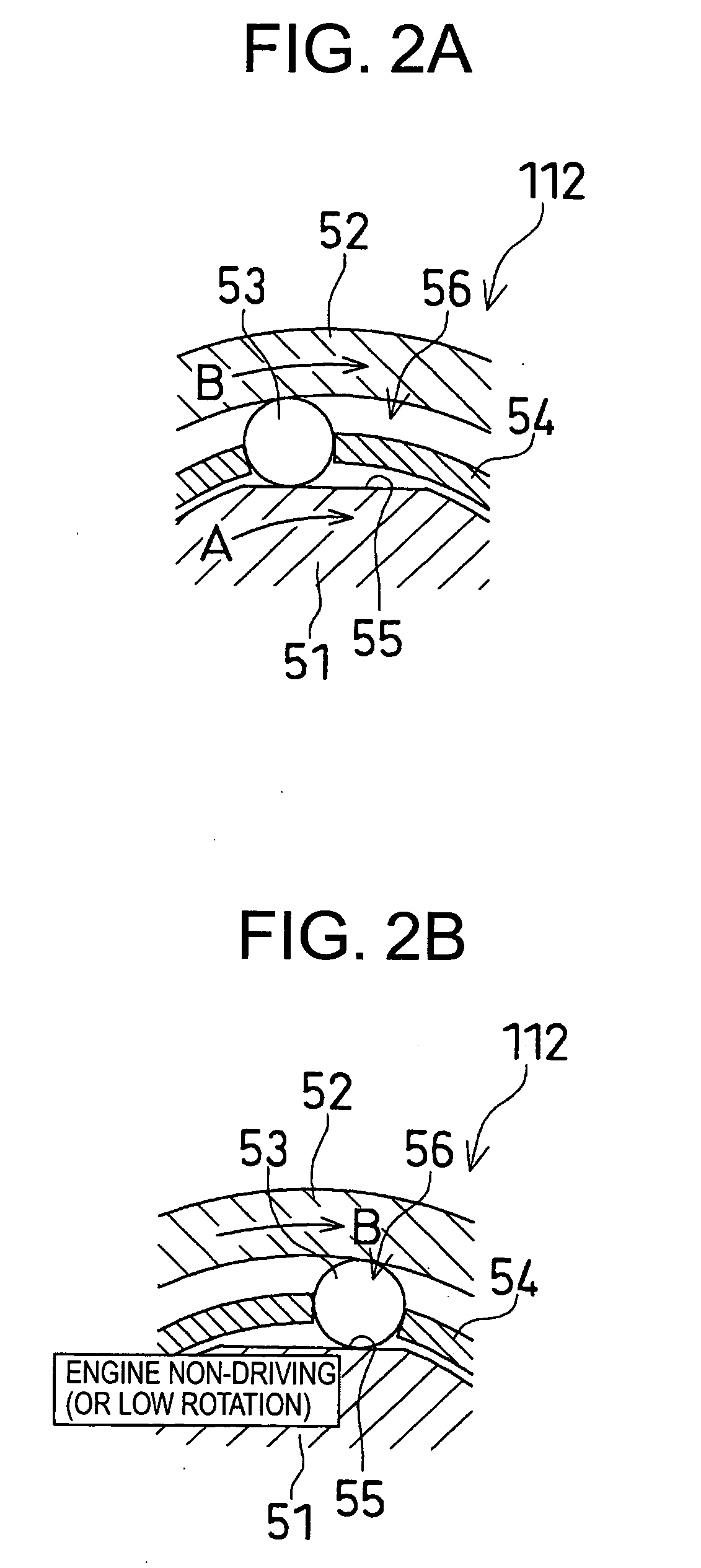

[0019]Next, an embodiment of the present invention will be described. FIG. 1 is a block diagram showing a forklift equipped with a cargo handling apparatus according to an embodiment of the present invention, FIG. 2A is a partial sectional view showing a two-way clutch in a first state, and FIG. 2B is a partial sectional view showing a the two-way clutch in a second state.

[0020]FIG. 1 shows the general construction of a cargo handling apparatus (working device) 201 of a forklift 101 as a working industrial vehicle. The cargo handling apparatus 201 is mainly composed of an engine 111, a generator motor 113, a battery (electricity storage means) 115, a cargo handling pump 117, a cargo handling valve 119, a fork 118, a traveling motor 121, a traveling unit 123, an inverter assembly 131, and an ECU (control means) 135. The cargo handling pump 117, the fork 118, and the cargo handling valve 119 form a cargo handling means (working means). In this embodiment, the cargo handling pump 117 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com