Method of providing a dart line for a dartboard and apparatus for producing the same

a dart board and dart line technology, applied in the field of dart boards, can solve the problems of players having difficulty seeing the worn strip of tape, adhesive tape is not a desirable way to mark a line, and the tendency of adhesive tape to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

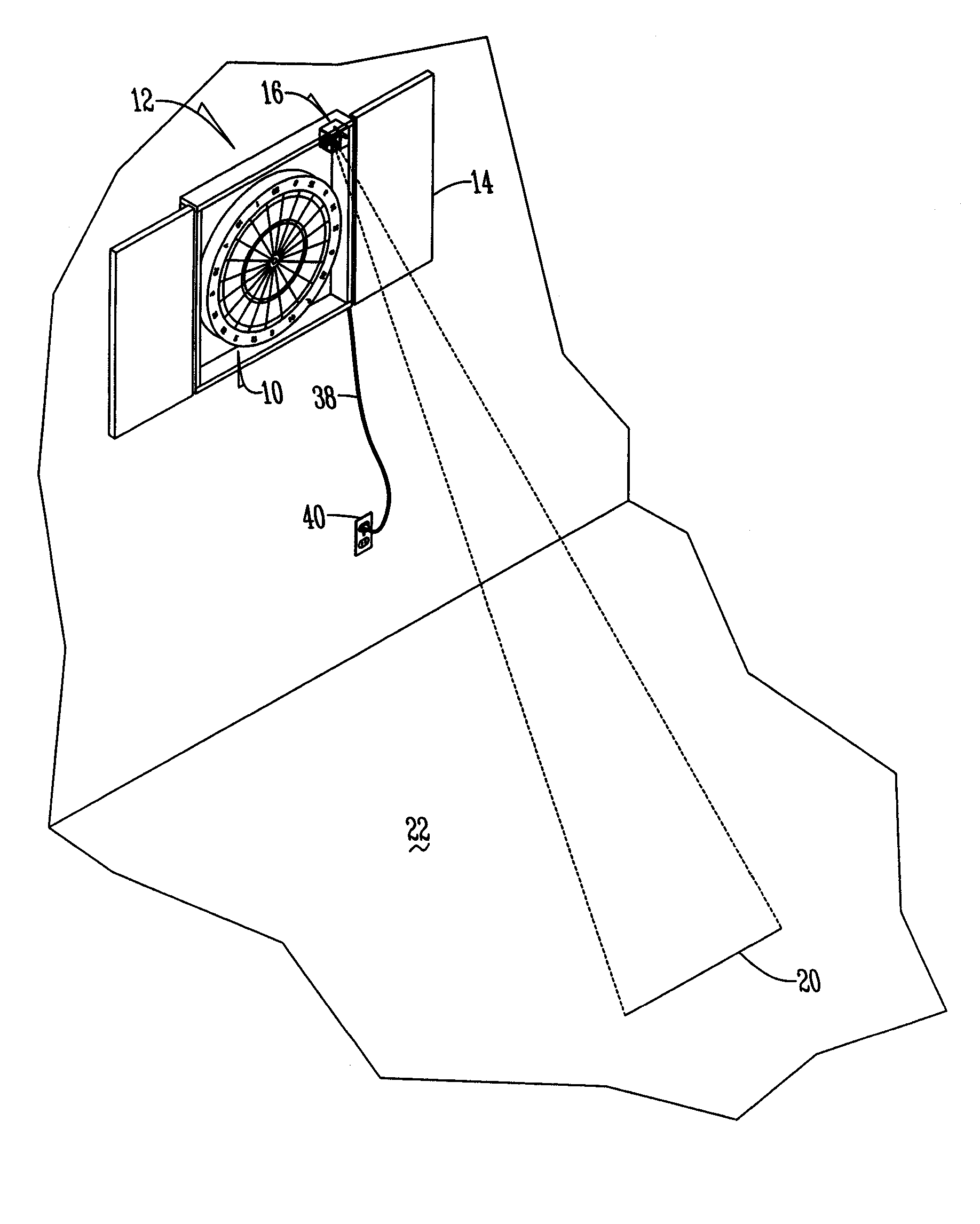

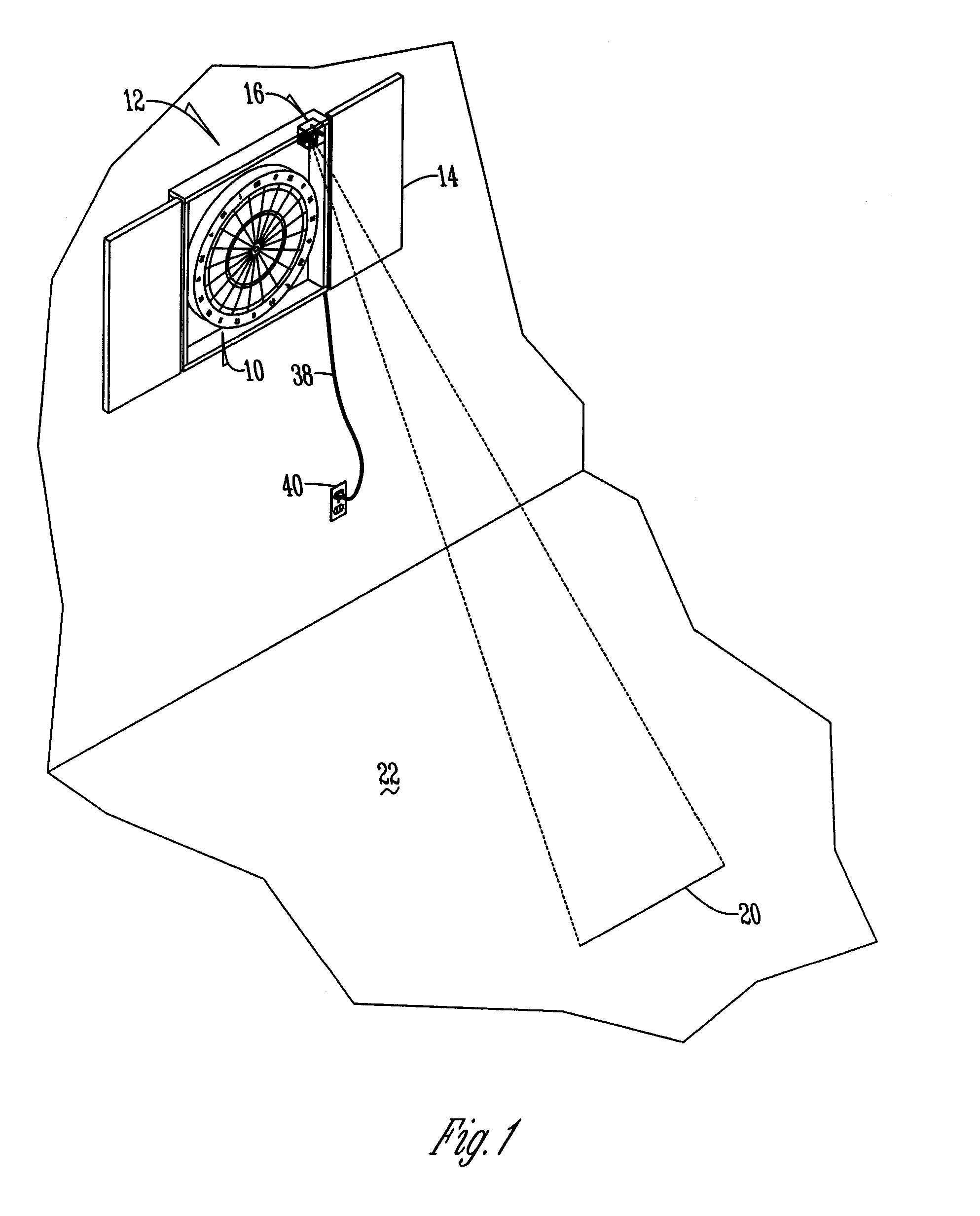

[0012]FIG. 1 shows a conventional dartboard 10 contained within a dartboard housing 12 having a pair of doors 14 that move from a open (FIG. 1) to a closed (FIG. 3) position. Mounted within the dartboard housing 12 is a laser housing 16 (FIG. 2) that has a laser 18 therein for projecting a dart line 20 on a floor 22.

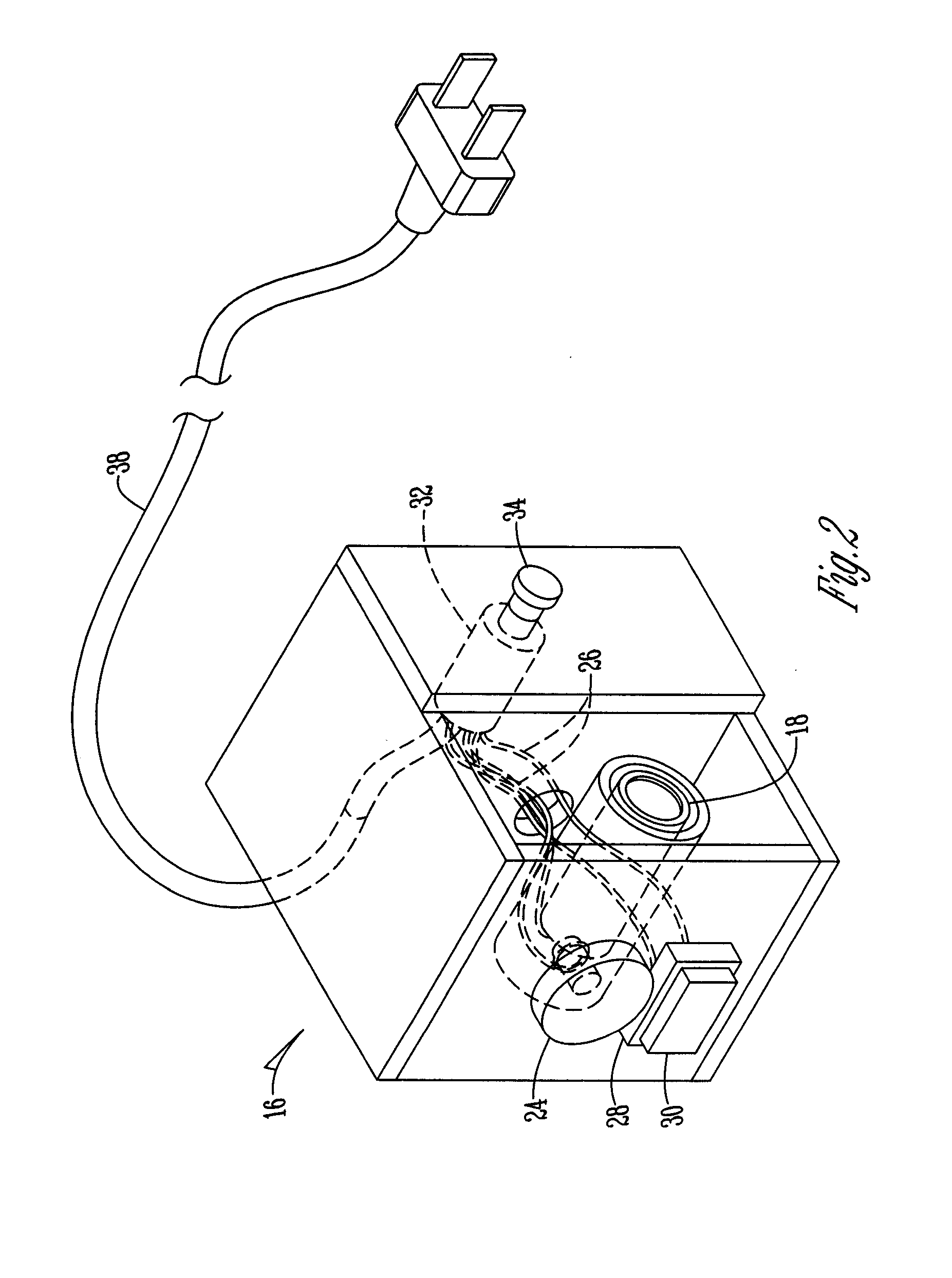

[0013] As best shown in FIG. 2 the housing 12 has a laser 18 rotatably mounted therein. The laser 18 is connected to an adjusting mechanism 24 such as a turning knob that allows the laser to be moved longitudinally to change the angle of the laser. Though in a preferred embodiment a turning knob is used, other adjusting mechanisms can be used such as a rotating lever, a ratcheting member that moves a stationary angled laser longitudinally, or the like. Thus, the distance of the dart line 20 from the dartboard 10 may be adjusted as needed. The laser 18 is powered by any means such as battery, or in a preferred embodiment the laser 18 is electrically powered using a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com