Internal Combustion Engine and Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

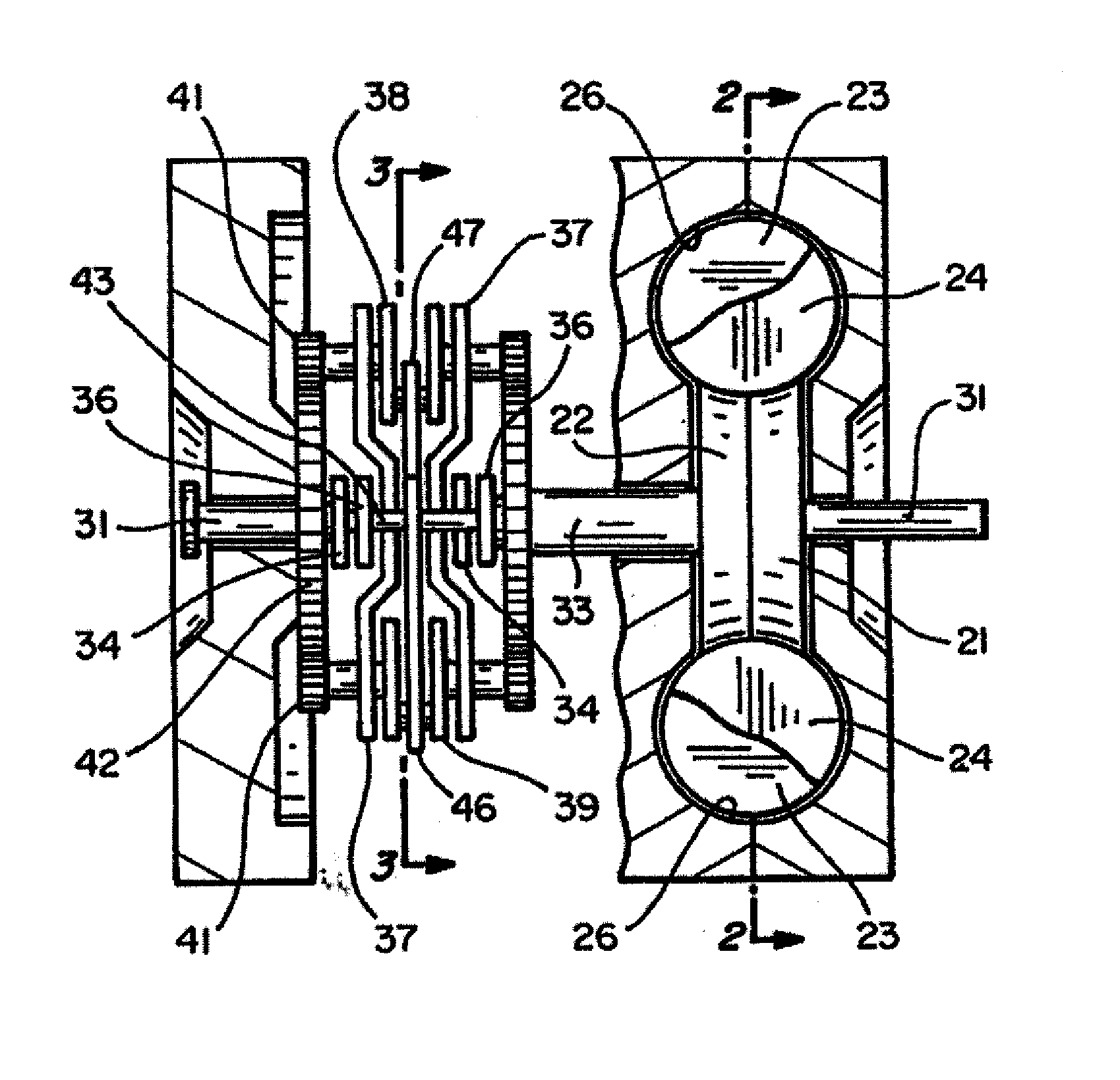

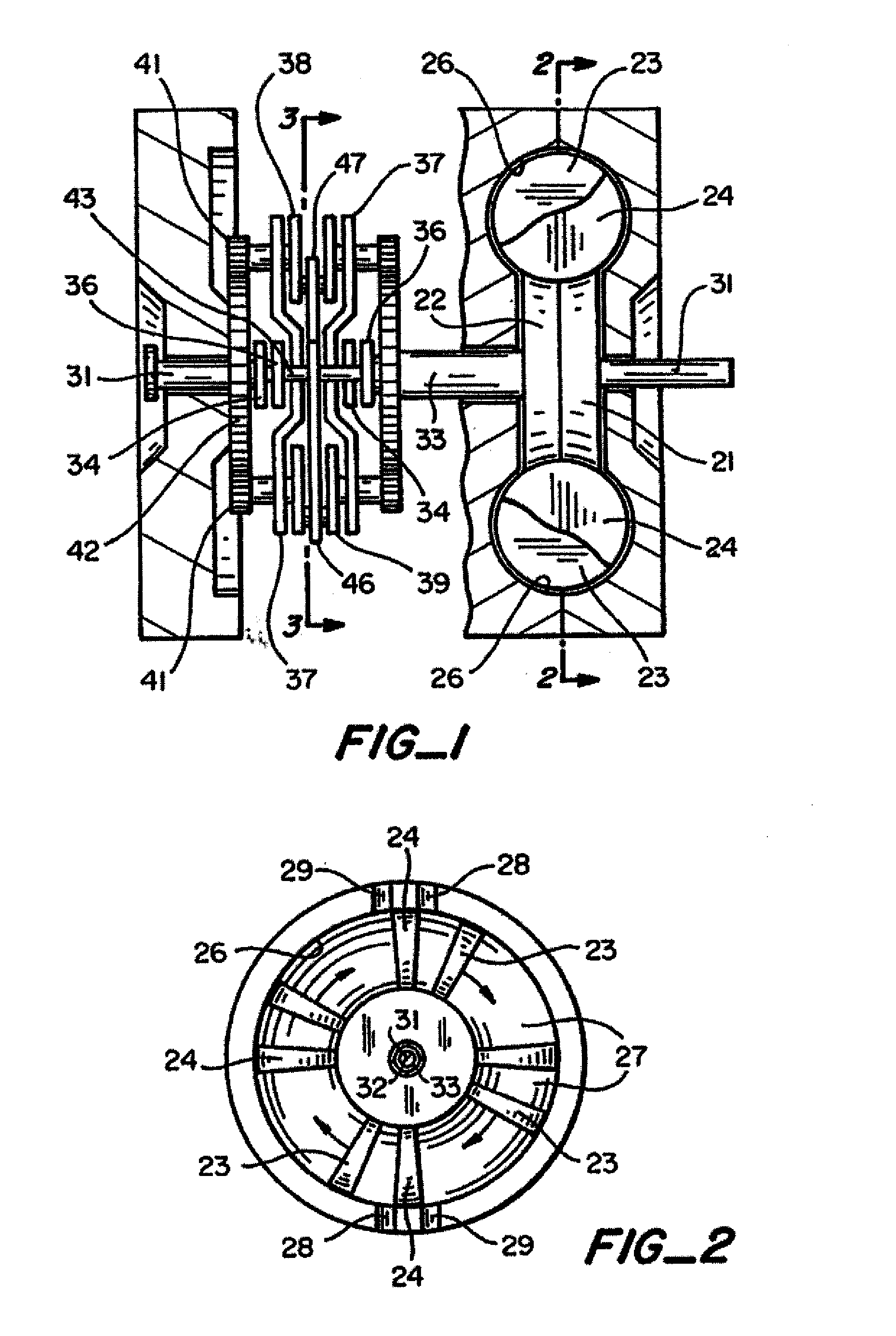

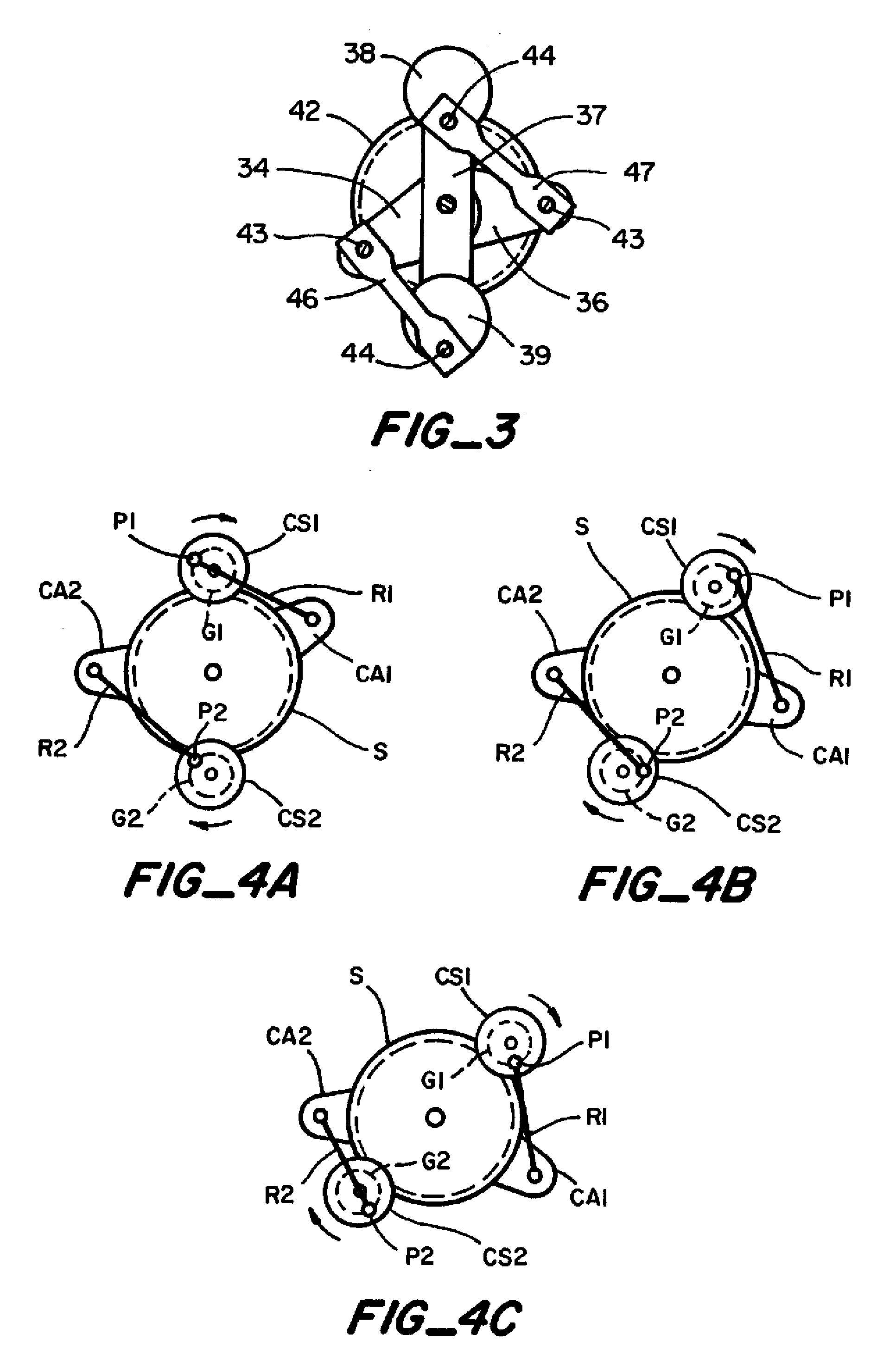

[0033] As illustrated in FIGS. 1-3, the engine has a pair of rotors 21, 22 with pistons 23, 24 which are spaced circumferentially of the rotors and disposed within a toroidal chamber or cylinder 26. The pistons on the two rotors are interposed between each other around the cylinder, with chambers 27 being formed between successive pistons on the two rotors. As discussed more fully hereinafter, the two rotors turn alternately and in stepwise fashion, with the pistons on one rotor remaining substantially stationary while the pistons on the other advance. Chambers 27 vary in volume as the pistons advance, with the chambers on the back sides of the moving pistons increasing in volume and the chambers on the front sides decreasing. With the alternating movement of the rotors, chambers which increase in volume during one step will decrease during the next.

[0034] Fuel is introduced into the chambers through intake ports 28, and spent gases are expelled through exhaust ports 29. The ports ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com