Sump pump system

a pump system and sump pump technology, applied in the direction of piston pumps, pump control, non-positive displacement fluid engines, etc., can solve the problems of no monitoring of the condition of the back-up battery, no way of increasing the pump discharge rate, and no way to display the expected battery life to the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

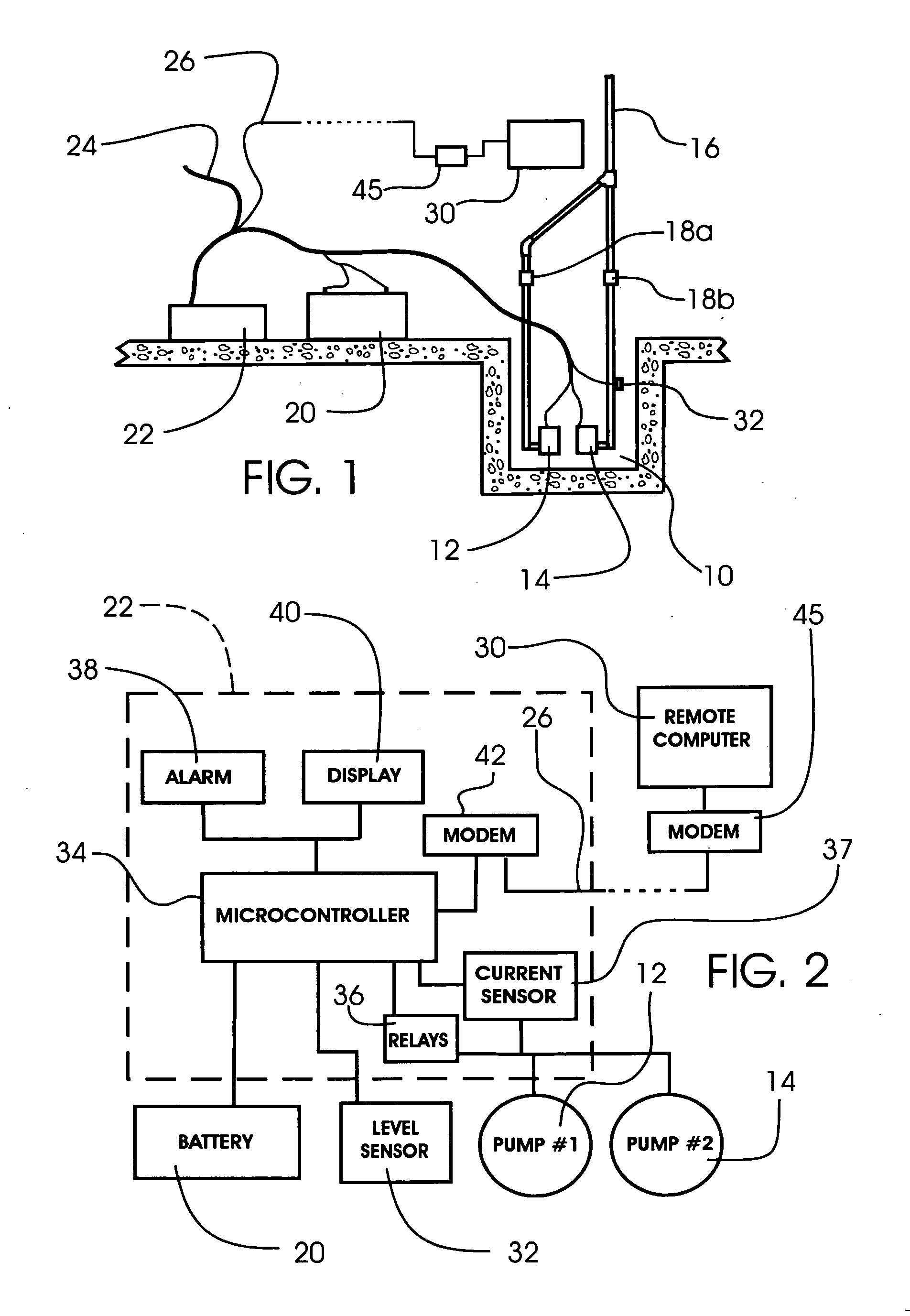

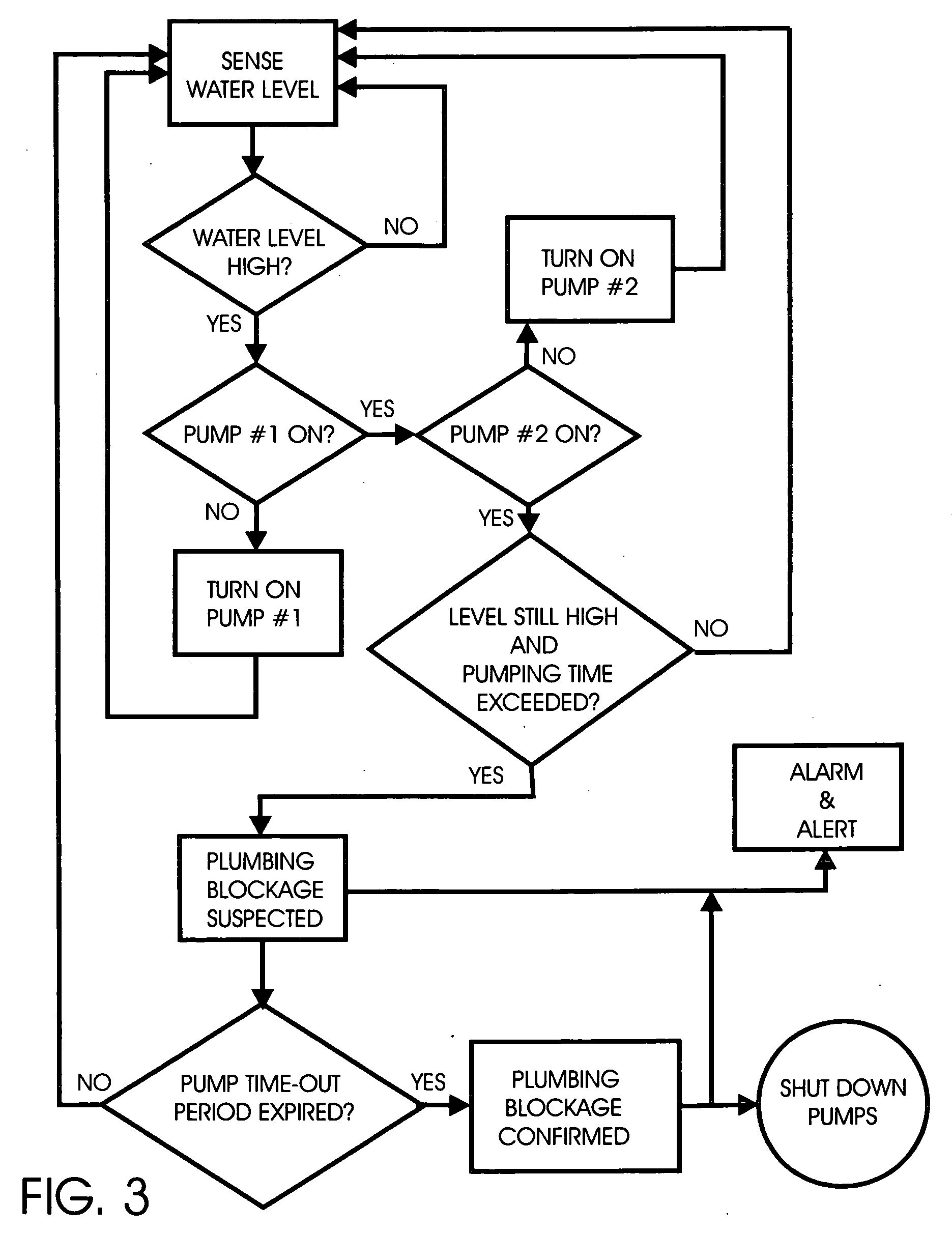

[0032] Turning first to FIG. 1 there is shown a representation of a sump or pit 10 and a pump system in accordance with the present invention for evacuating liquid from the sump. (This pump system may be employed in addition to any other pump system currently in the sump or as the sole pump system in the sump.) Positioned within the sump 10, a first pump 12 and a second pump 14 are shown; but it is to be understood that multiple additional pumps may be employed in the same manner as herein described, and such is considered to be within the scope of this invention.

[0033] The pumps of the present invention are preferably identical electrical motor driven pumps of the usual submersible variety well known in the art for operation within a sump environment, and they are connected therein in the usual manner for pumping liquid from the sump when switched ON. For purposes of this description, the reference herein to a pump being switched ON, or being in an ON condition, shall mean the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com