Super-sparger microcarrier beads and precision extrusion deposited poly-epsilon-caprolactone structures for biological applications

a technology of polyepsiloncaprolactone and microcarrier beads, which is applied in the field of microcarrier beads, can solve the problems of high cell yield, difficult culture of anchorage dependent cells to commercial yield, and insufficient cell survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

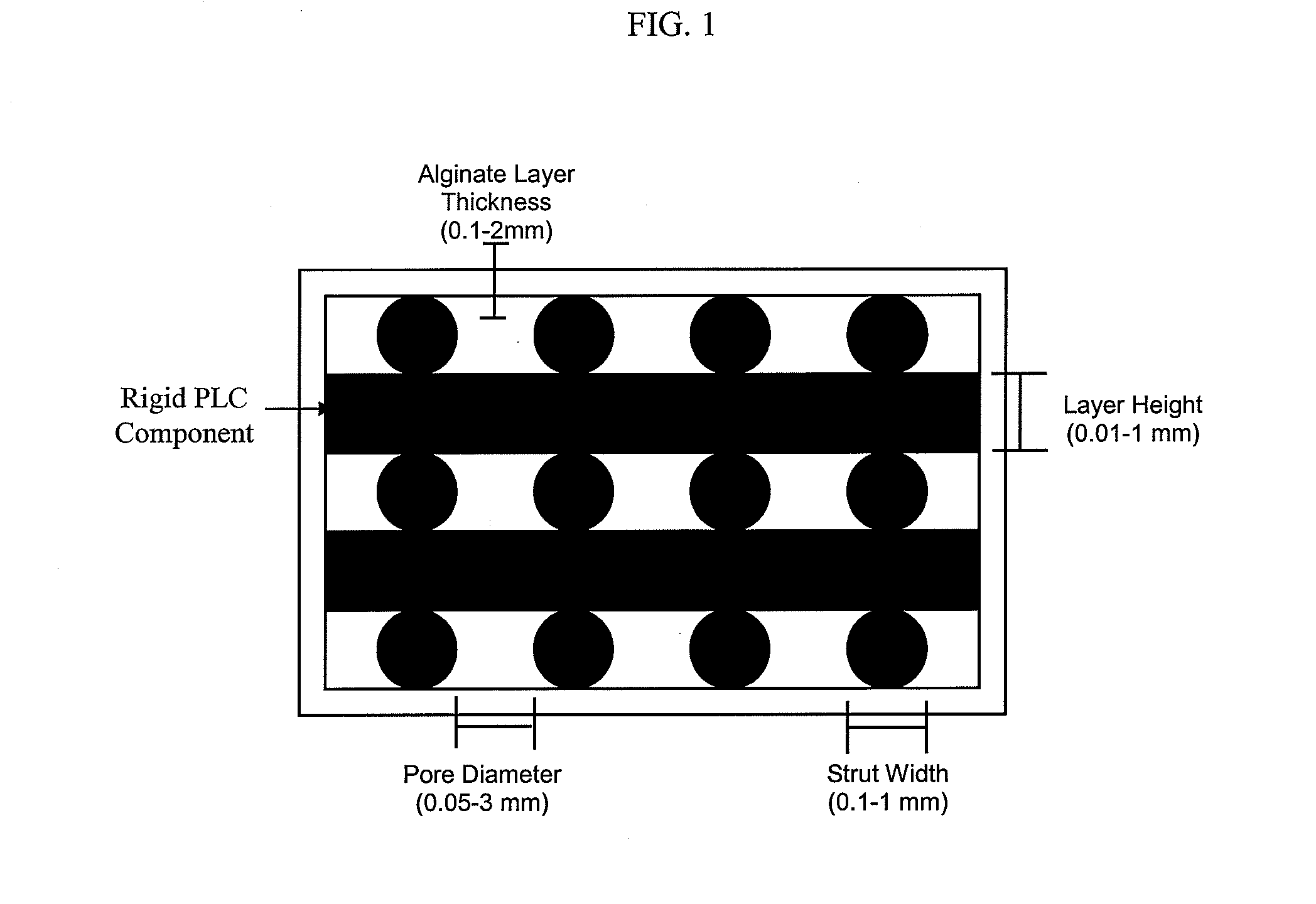

[0051] The invention relates to a microcarrier bead which comprises (a) a polymeric porous three-dimensional body having a customized porosity between 15-90% empty space by volume such that at least 99% of pores are interconnected and have diameters of less than 200 microns and preferably, less than 100 microns, (b) an outer protective layer and optionally (c) a filler. Advantageously, the microcarrier beads of the invention provide large amounts of protected surface area for cell attachment within the reactor. Bubble and fluid kinetic resistance is provided through an outer protective layer such as a thin hydrogel layer at the perimeter of the porous bead. Such high porosity was achieved by using a novel method as described in detail below.

[0052] The protective layer of the microcarriers of the invention also allows for a more agitated fluid environment than survivable by cells on known in the art (e.g., CYTODEX and CULTISPHER beads). CULTISPHER beads are constructed of porous gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com