Adjustable Testing Tool and Method of Use

a testing tool and adjustment technology, applied in the direction of survey, wellbore/well accessories, sealing/packing, etc., can solve the problems of contaminating the formation fluid entering the tool, difficult to remove all of the wellbore fluid, and the methods applicable for reducing the contamination of fluids and other debris are not always applicable to reduce the contamination of fluids and other debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

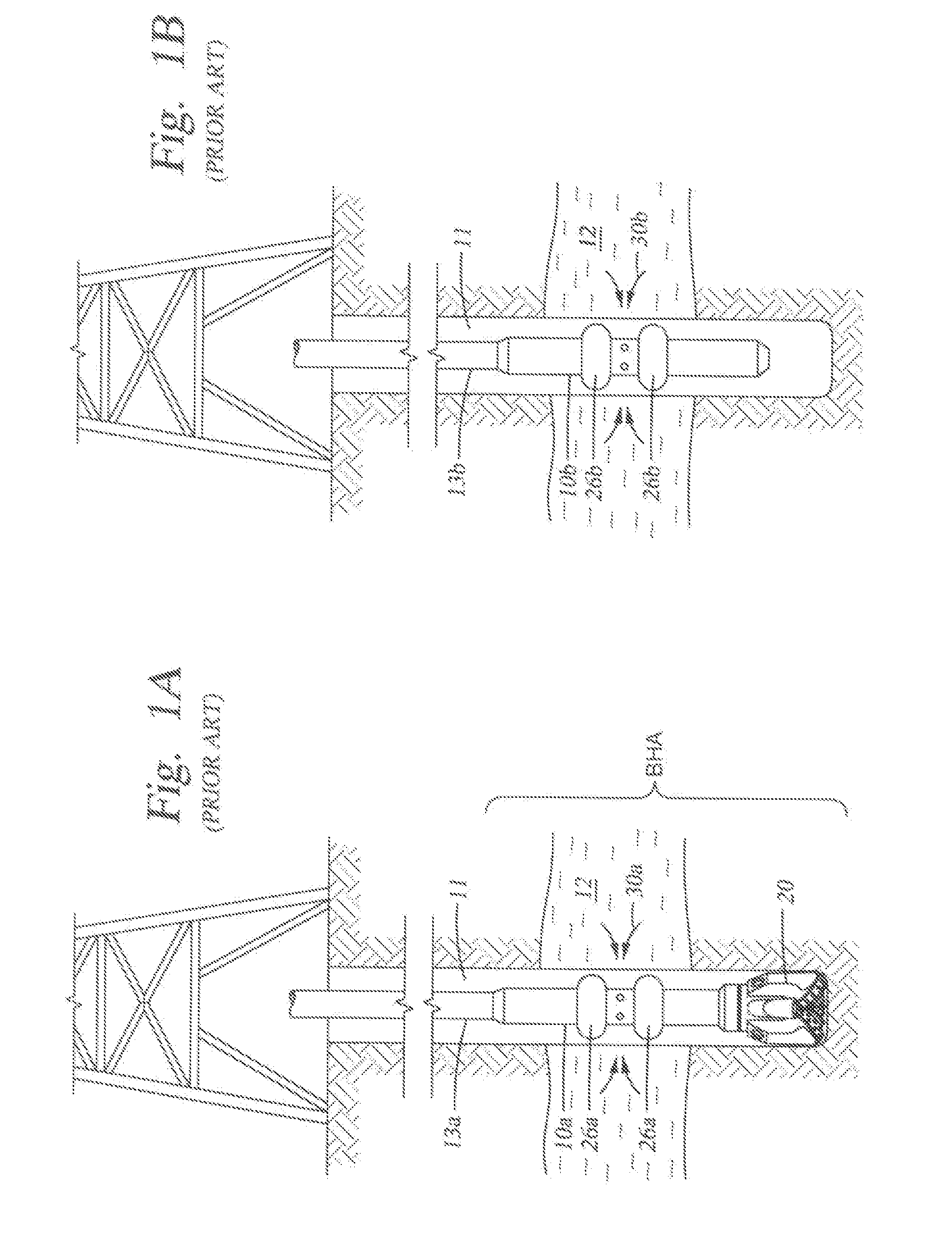

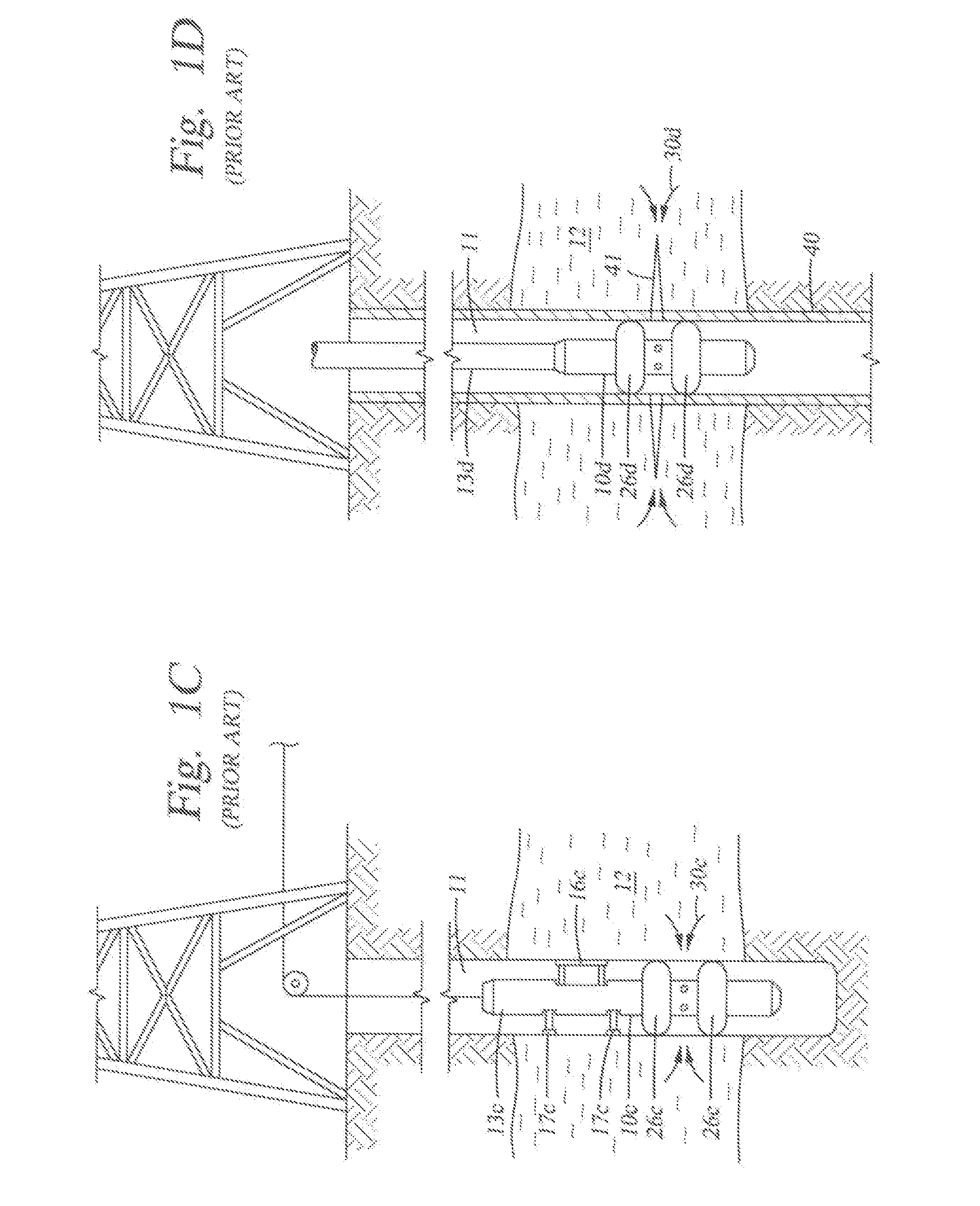

[0028]Certain examples are shown in the above identified figures and described in detail below. In describing these examples, like or identical reference numbers are used to identify common or similar elements. The figures are not necessarily to scale and certain features and certain view of the figures may be shown exaggerated in scale or in schematic for clarity and / or conciseness.

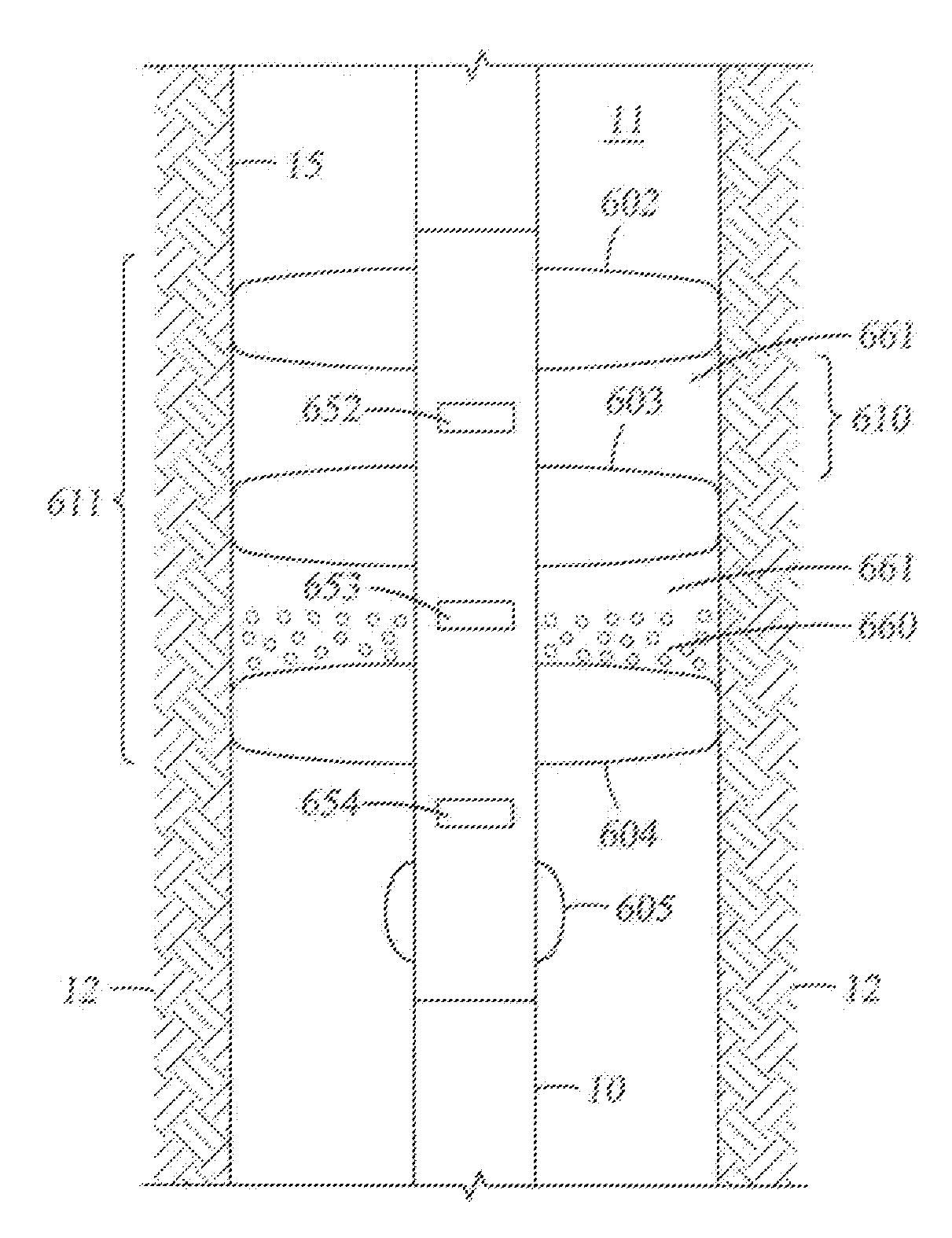

[0029]FIG. 2 shows one embodiment of a testing tool capable of sealing wellbore intervals of various lengths. The testing tool 10 is conveyed within wellbore 11 created in formation 12 via conveyance mean 13. The testing tool 10 can be conveyed downhole using a wireline cable after the well has been drilled and the drill string removed from the wellbore. Alternatively, the testing tool can be conveyed downhole on the drill string used to drill the wellbore. Any conveyance mean known in the art can be used to convey the tool 10. Optionally, the conveyance mean allows for two ways communication between too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com