Monolithic integration of non-planar solar cells

a solar cell and monolithic technology, applied in the solar field, can solve the problems of shunting across the junction, reducing the efficiency of increasing the occurrence of pinholes and similar flaws in larger planar solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

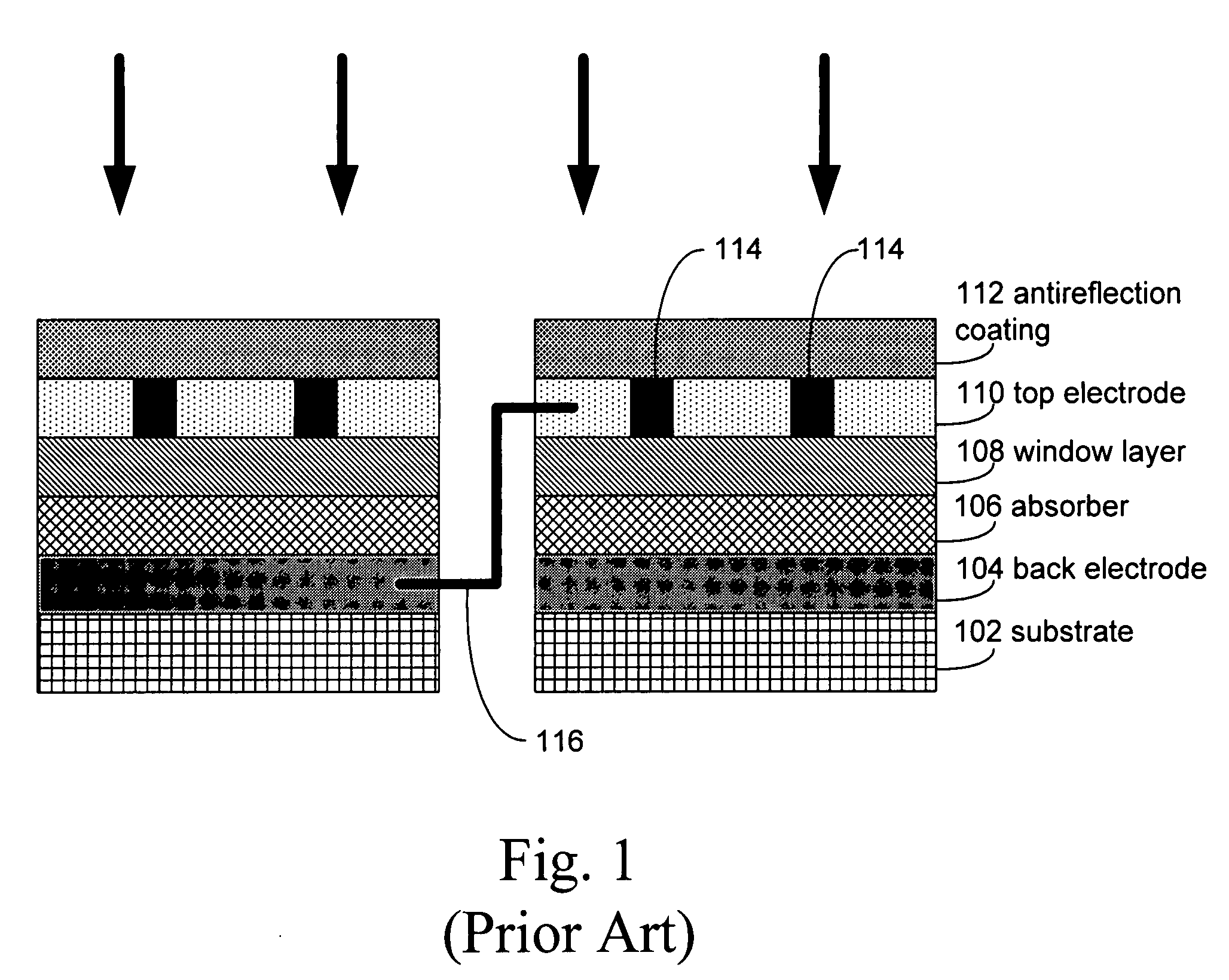

[0043]Disclosed herein are solar cell units comprising a plurality of photovoltaic cells linearly arranged on a substrate in a monolithically integrated manner.

5.1 Basic Structure

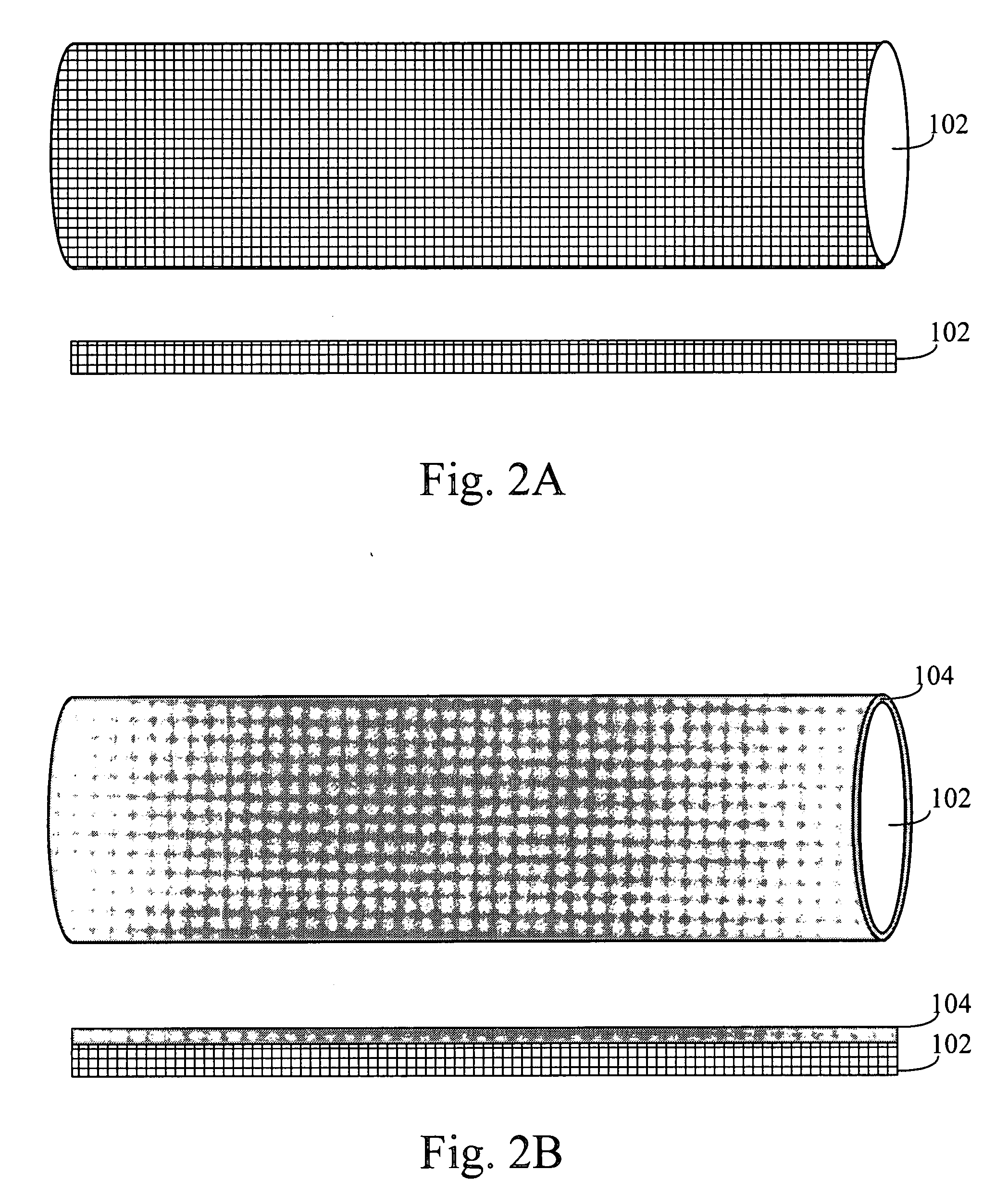

[0044]FIG. 7 illustrates the cross-sectional view of an exemplary embodiment of a photovoltaic cell 700. In some embodiments, a solar cell unit comprises a plurality of photovoltaic cells 700 linearly arranged on substrate in a monolithically integrated manner. In some embodiments, the substrate is either (i) tubular shaped or (ii) a rigid solid rod shaped. In some embodiments the substrate is flexible tubular shaped.

[0045]Substrate 102. A substrate 102 serves as a substrate for the solar cell unit. In some embodiments, substrate 102 is either (i) tubular shaped or (ii) a rigid solid rod shaped. In some embodiments substrate 102 is any solid cylindrical shape or hollowed cylindrical shape. When substrate 102 is tubular shaped it can be either rigid or flexible. For example, in some embodiments substrate 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com