Automatic vibratory separator

a vibratory separator and automatic technology, applied in the direction of filtration separation, separation process, borehole/well accessories, etc., can solve the problems of large undesirable particles, too quickly or without sufficient weight to be filtered adequately, fluid or material that is too deep may not be adequately filtered, etc., to achieve the effect of affecting screening efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

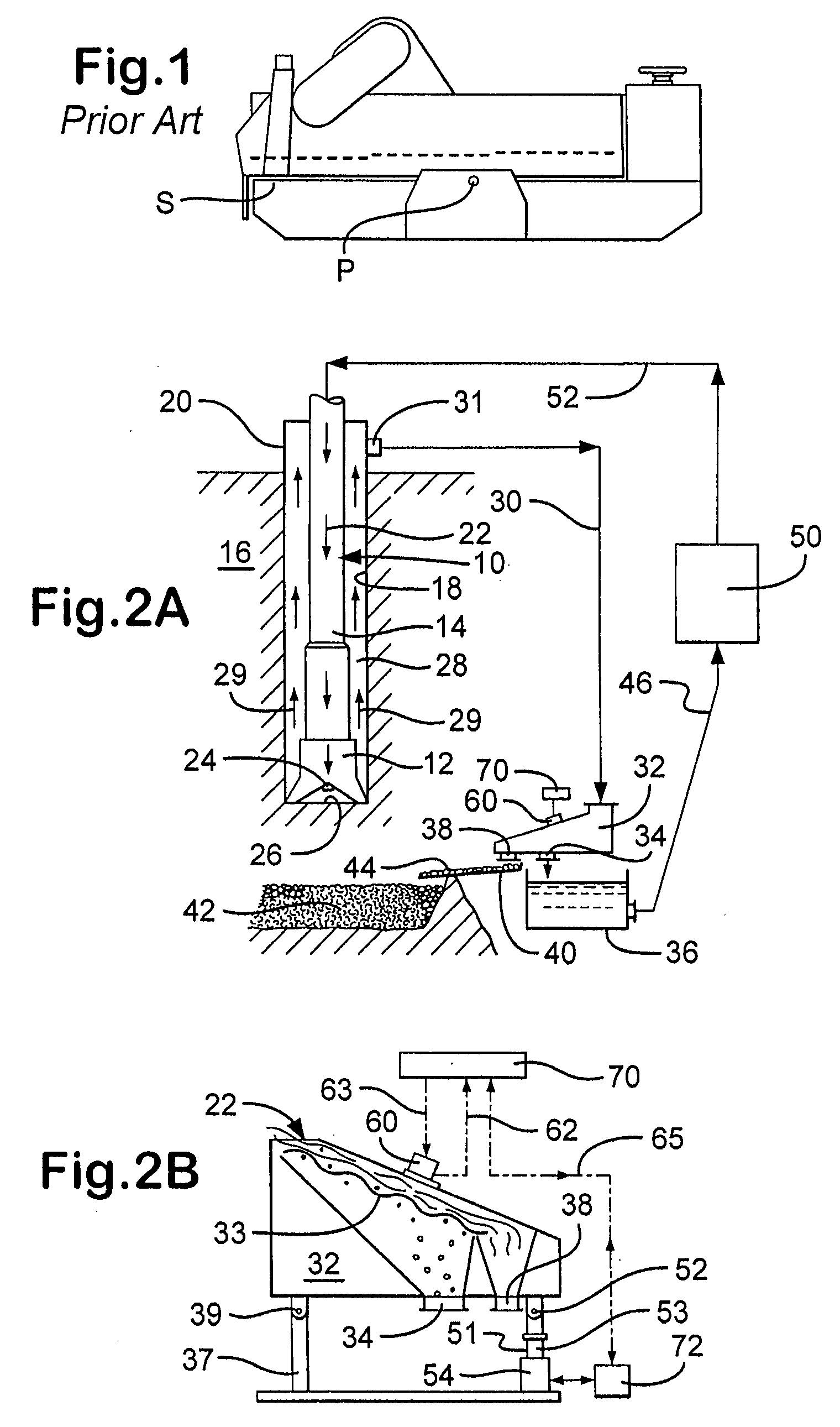

[0087]Referring now to FIGS. 2A and 2B, a drilling system 10 according to the present invention includes a rotary bit 12 attached to the lower end of a length of hollow drill pipe 14 suspended from a drilling derrick (not shown).

[0088]The drill pipe 14 and attached drill bit 12 are rotated to cut into the subsurface formation 16 to form a wellbore 18. The drill pipe 14 passes through a wellhead assembly 20 located at the surface. The wellhead assembly 20 controls flow of drilling fluid into the well. During the drilling of the well, a drilling fluid 22 commonly referred to as drilling mud is pumped down the interior of the hollow drill pipe 14. The drilling mud exits jets such as jet 24 in drill bit 12 and impinges upon a bottom 26 of the well bore 18. The drilling fluid exiting the jets 24 flushes away from the bottom 26 of the wellbore 18 the cuttings or particles generated as the drill bit 12 cuts into the earthen formation 16. A stream of drilling mud 22 then carries the cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com