High efficiency, peak-power reducing, domestic hot water heater

a technology of high efficiency and peak power, which is applied in the direction of fluid heaters, electric heating, electrical equipment, etc., can solve the problems of high instantaneous demand at re-activation, high instantaneous demand of power on the electrical distribution network, and high cost of utilities, so as to reduce the amount of hot water, reduce the propagation of harmful bacteria, and reduce the kilowatt demand of domestic hot water heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

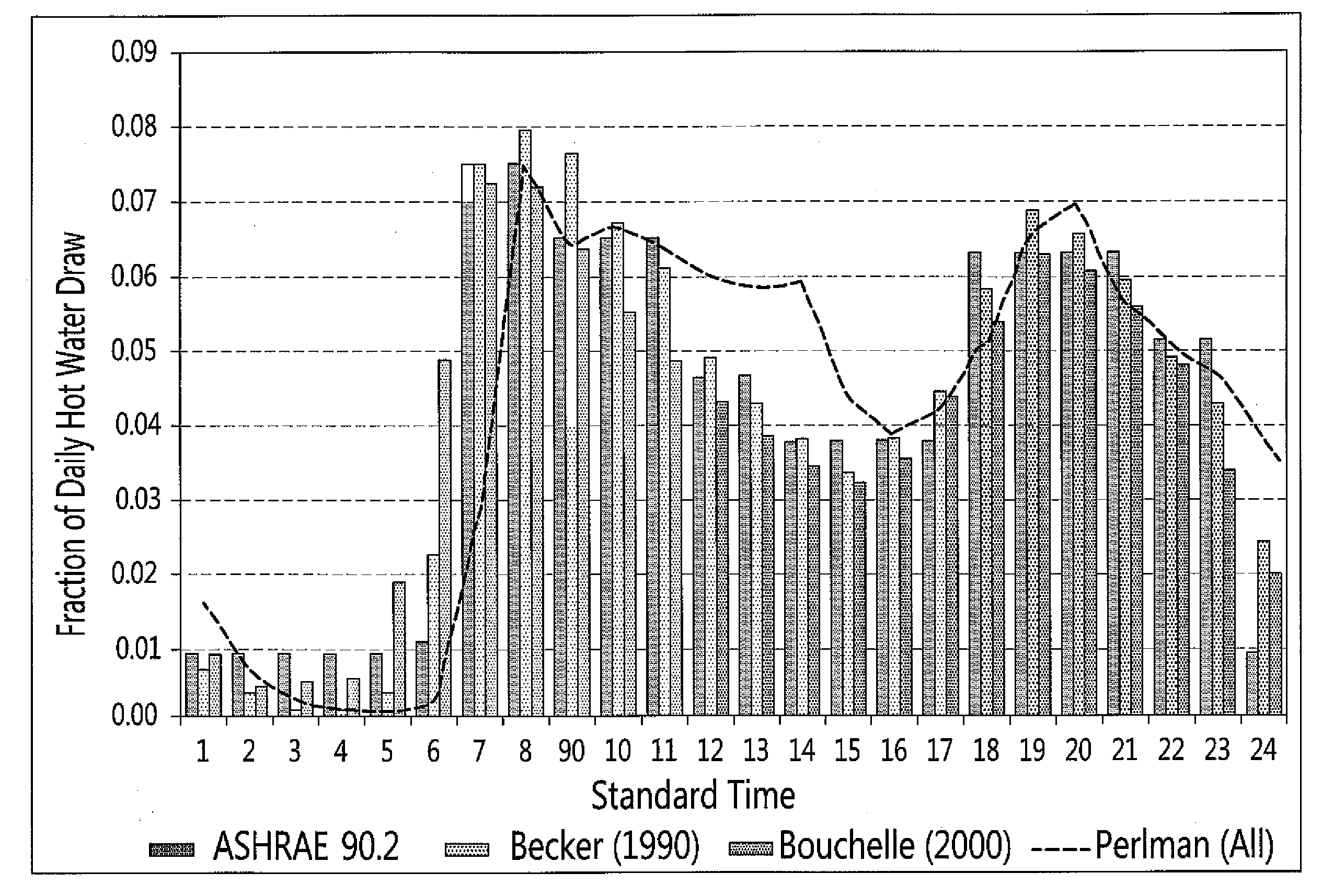

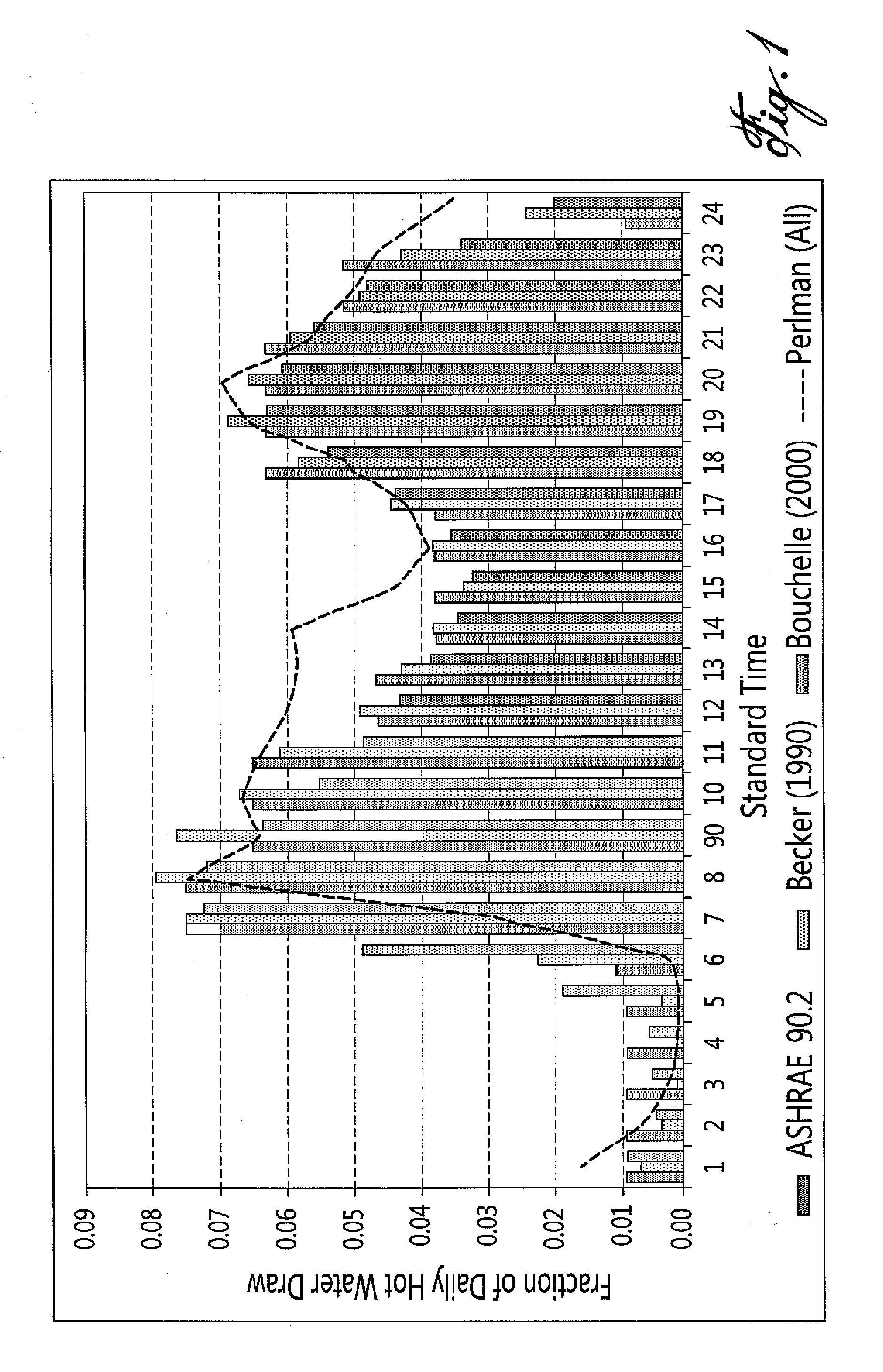

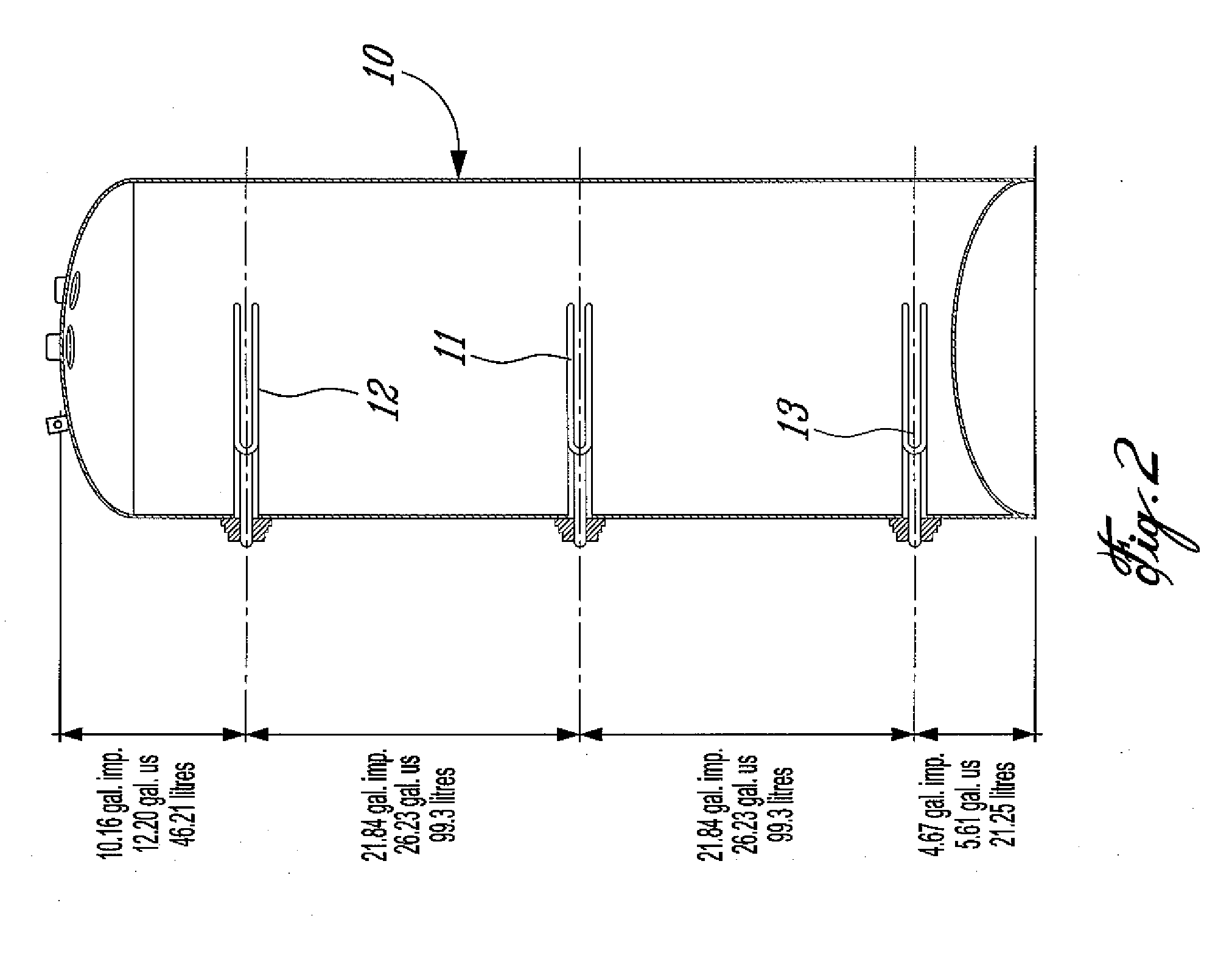

[0032]Although it is stated in the above referred-to U.S. patent that any size of tank can be used, one must be careful in the actual position of the elements in order to insure that end users do not run out of hot water and that the intermediate element does not activate unless absolutely necessary. Furthermore, it is not recommendable that the actual size of the tank be less than 270 liters in cold climate geographical areas due to the fact that a smaller tank will not provide the appropriate amount of hot water requested by a user during peak periods. Warmer climates where tank inlet water temperatures are higher than in northern areas of North-America, could most likely allow smaller volume tanks such as 180 liters. Nonetheless, hot water drawing trends must be looked at. As such, the following table exposes figures of the average hot water consumption. These were taken from ASHRAE Standard.

Average Hot Water Use, LHourlyDailyWeeklyMonthlyGroupOVLPeakOVLPeakOVLPeakOVLPeakAll fami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com