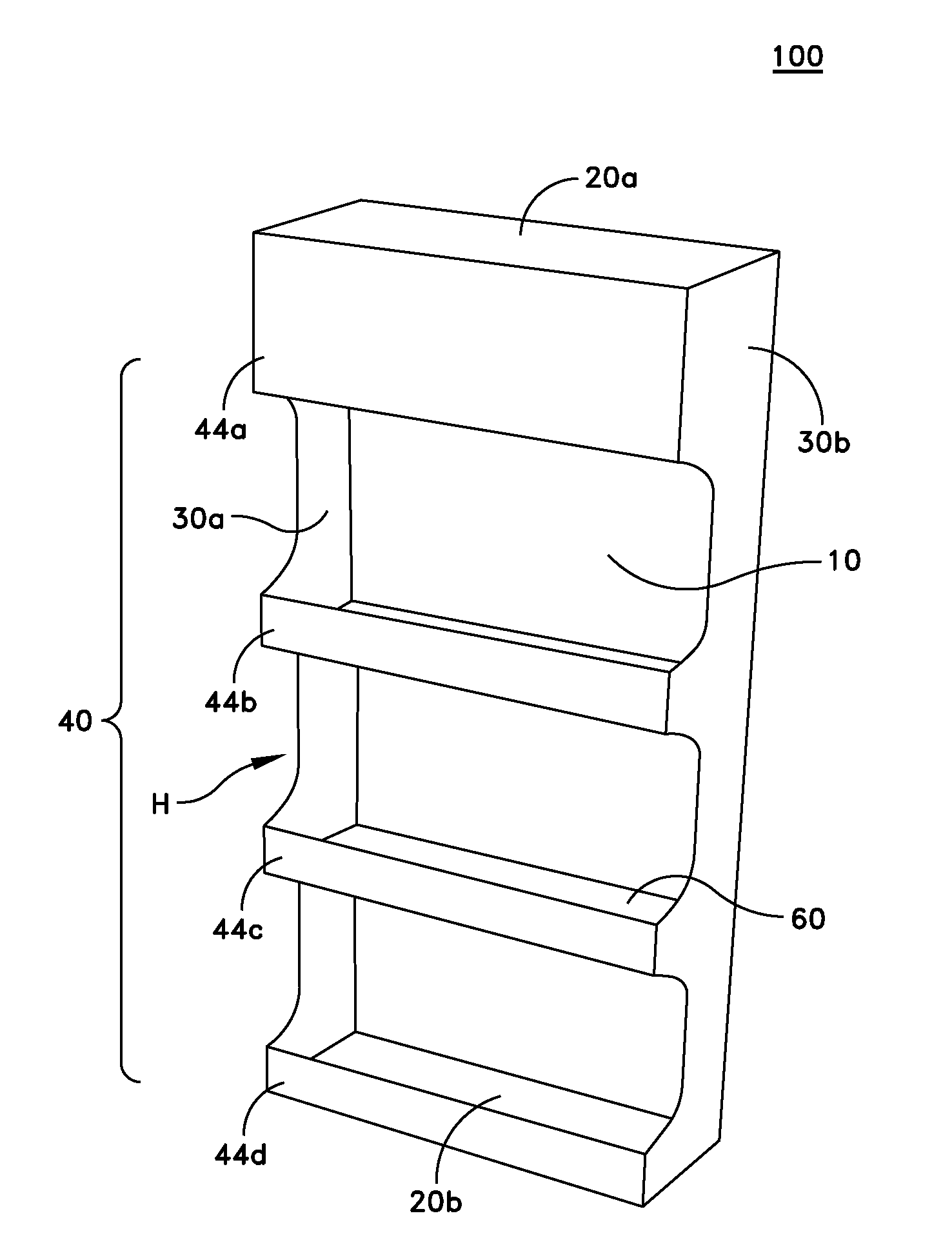

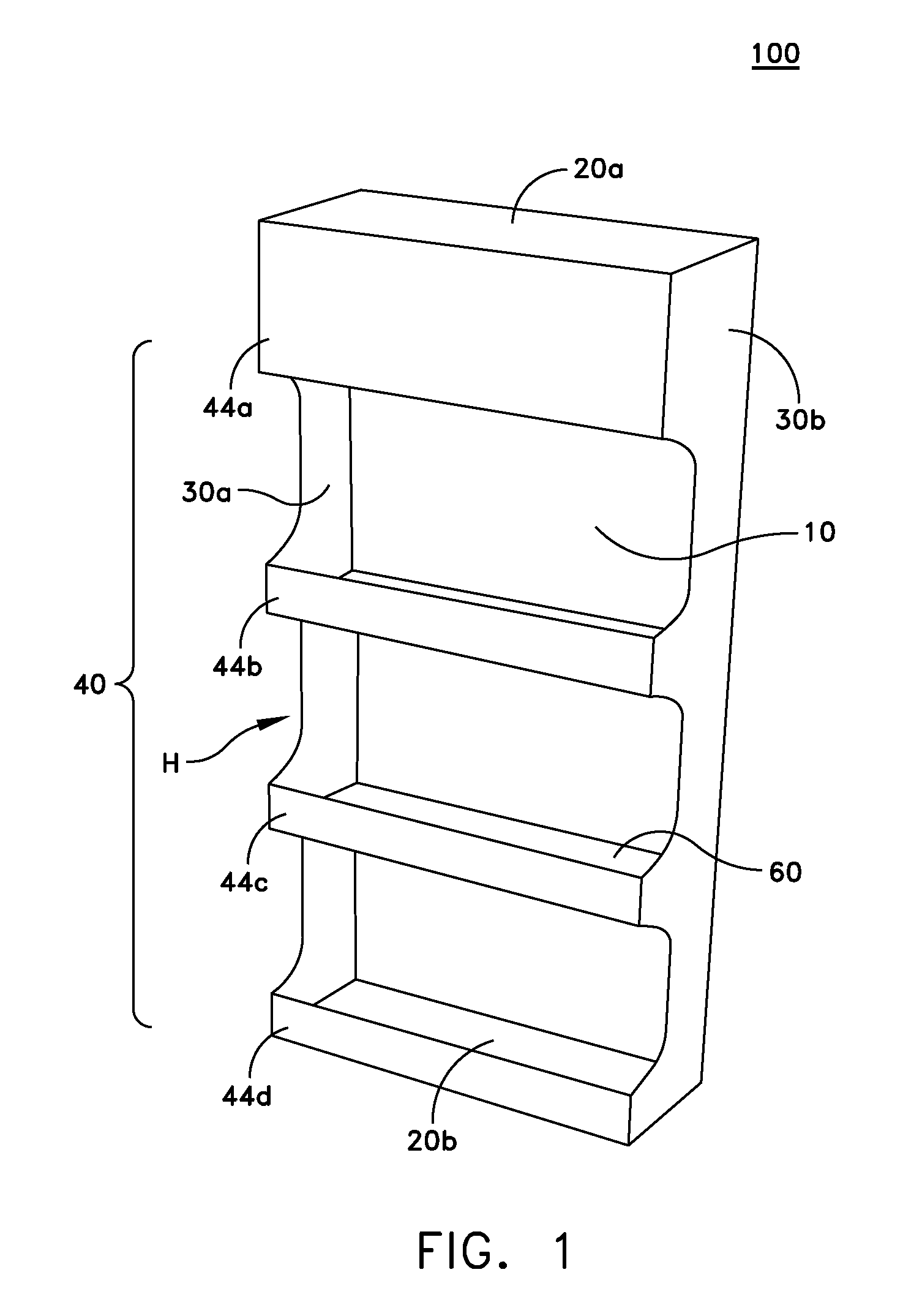

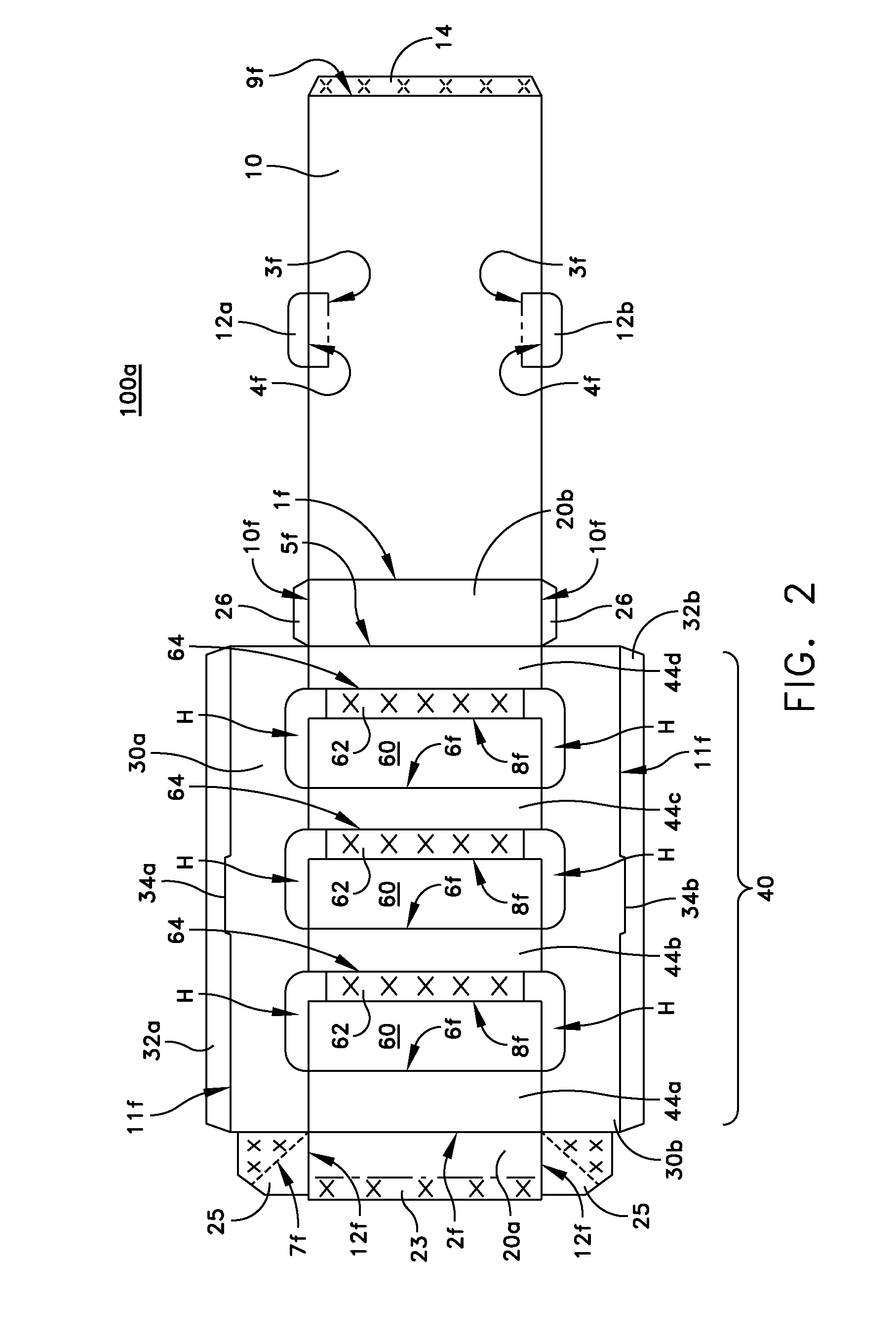

Folded and glued display container having integral shelf elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]As will be appreciated, terms such as “horizontal,”“vertical,”“left,”“right,”“up,”“down,”“top,”“bottom,”“front” and “back,” (etc.), used as nouns, adjectives or adverbs (e.g. “horizontally,”“rightward,”“upwardly,”“downwardly,” etc.) that appear in this description refer to the orientation of the structure of the invention as the container of the invention happens to be oriented in the particular drawing figure under consideration, with that figure facing the reader. Such terms are not intended to require or limit the invention to a particular orientation. Similarly, the terms “longitudinal” and “lateral” generally refer to the orientation of surfaces or other structures relative to an axis of elongation or axis of rotation, as appropriate.

[0029]The terms “connected” and “interconnected”, when used to describe the relationship between two or more structures, denote that the structures are secured or attached either directly or indirectly through intervening structures and inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com