Photovoltaic Roofing Wiring Array, Photovoltaic Roofing Wiring System and Roofs Using Them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

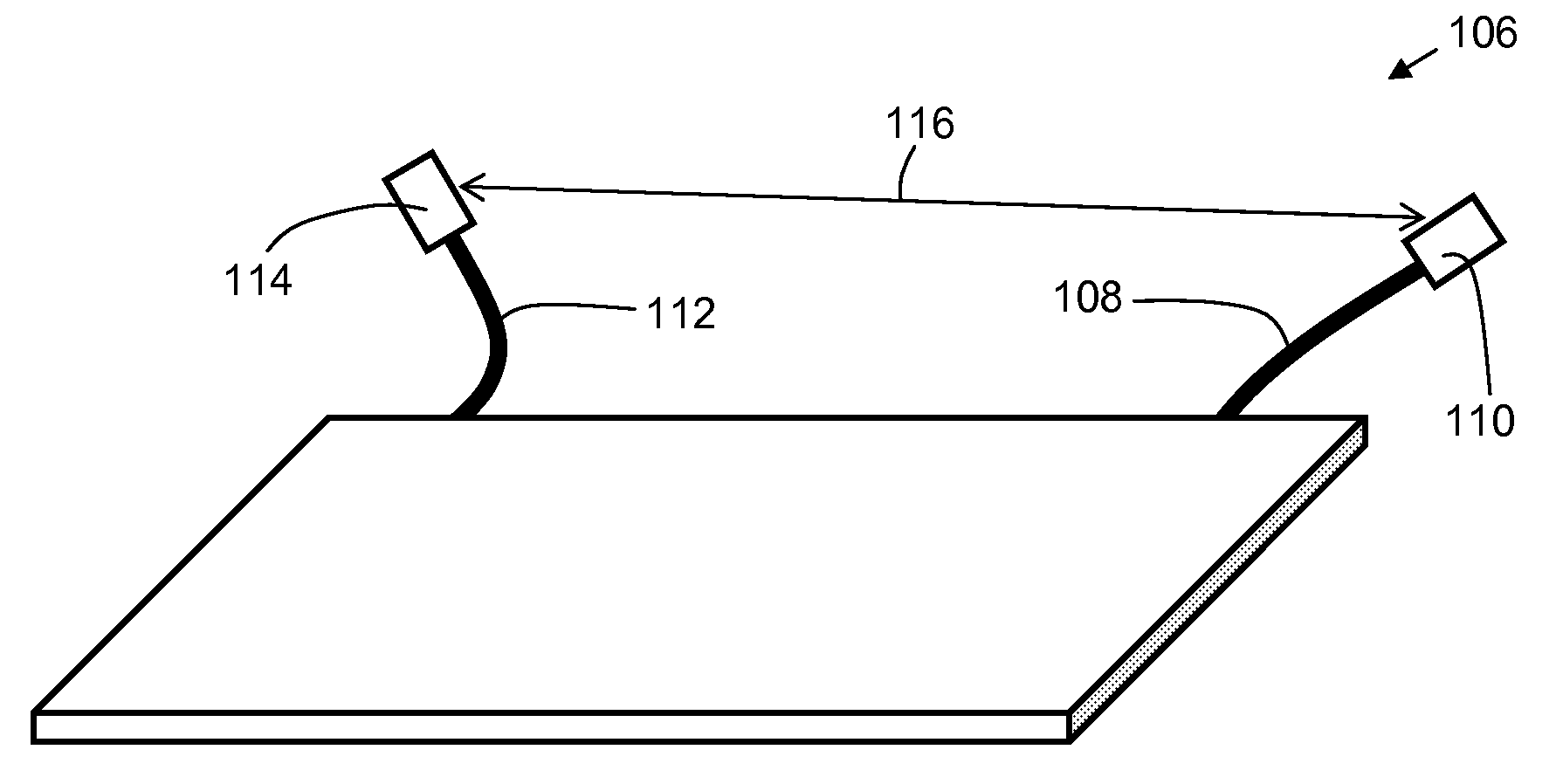

[0043]One aspect of the invention comprises a photovoltaic roofing wiring array configured for use with a photovoltaic element, an example of which is shown in top perspective view in FIG. 1. Photovoltaic element 106 includes a positive lead 108 terminated in a positive connector 110, and a negative lead 112 terminated in a negative connector 114. As shown in FIG. 1, the positive and negative leads may extend from the photovoltaic element. Alternatively, as the skilled artisan would appreciate, they can be integrally formed with the rest of the photovoltaic element, with the connectors mounted directly on the surface of the element. The lead-to-lead distance 116 is the distance spanning the connectorized ends of the leads of a single photovoltaic element. If one or both leads are flexible, the lead-to-lead distance is a range of distances, with a lower limit being the distance between the connectorized ends when they are brought together in closest proximity and an upper limit being...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap