Control method for a variable displacement refrigerant compressor in a high-efficiency AC system

a technology of variable displacement and compressor, which is applied in refrigeration components, transportation and packaging, light and heating equipment, etc., can solve the problems of high overall system cost, and achieve the effects of preventing compressor operation, and reducing the number of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

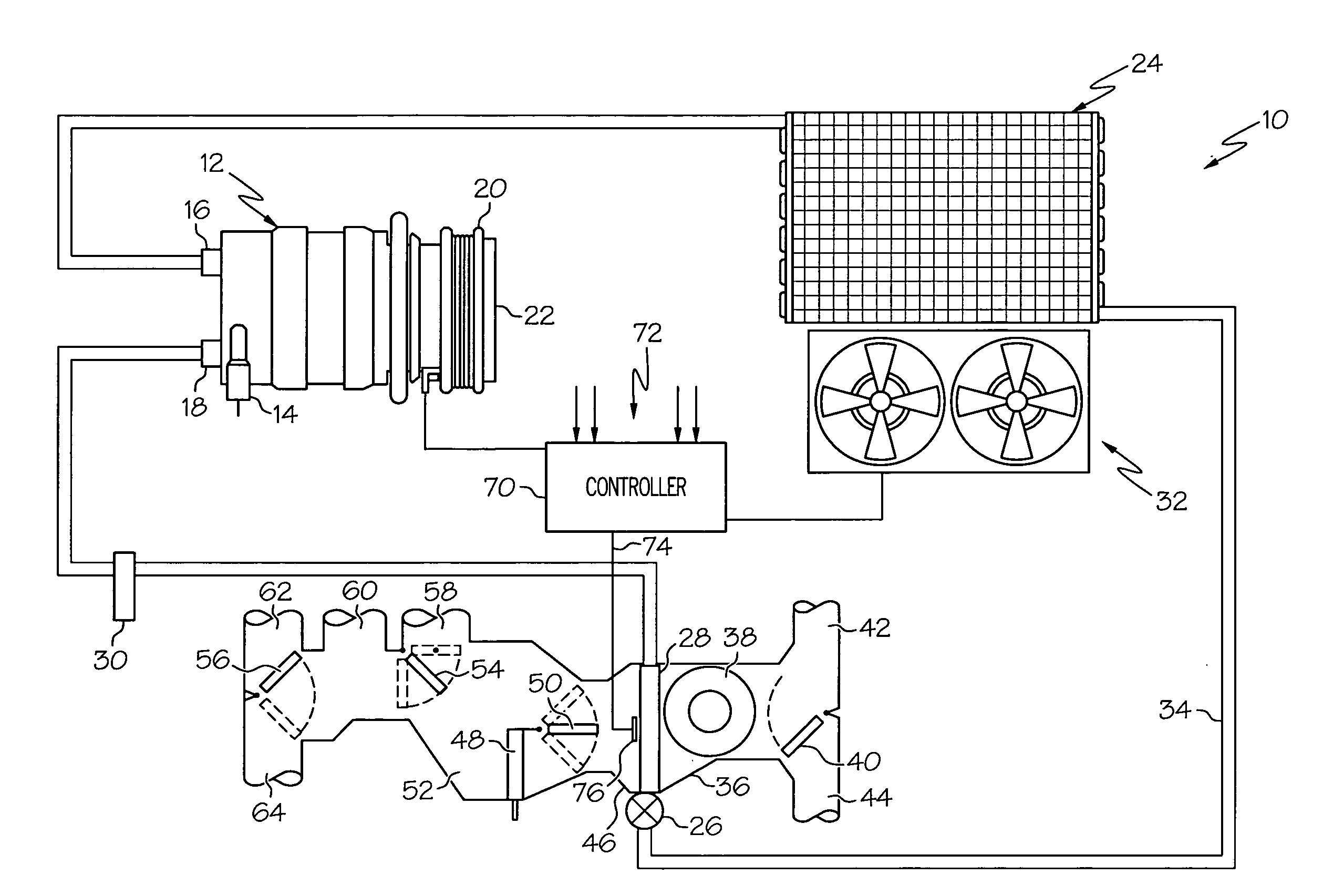

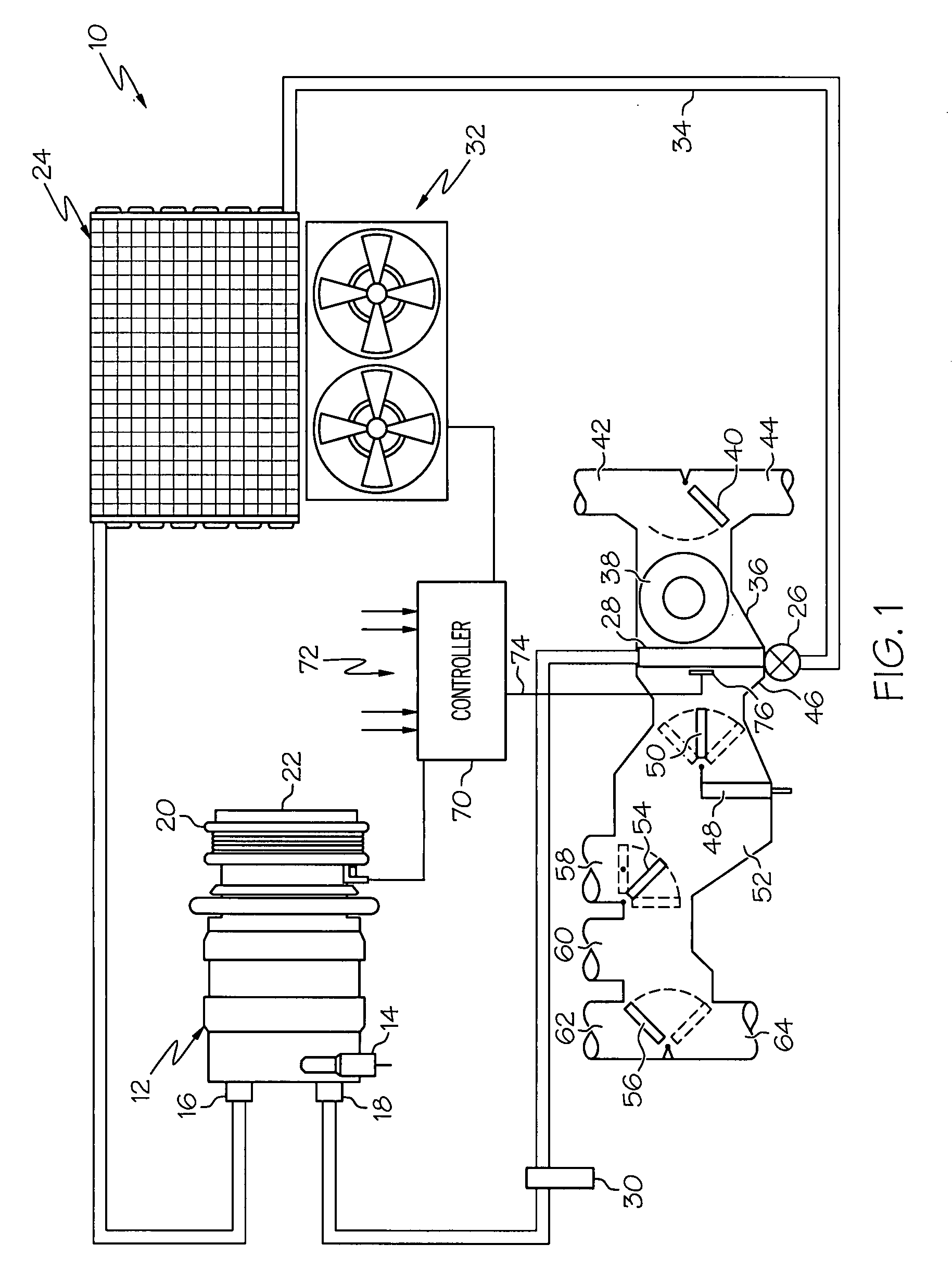

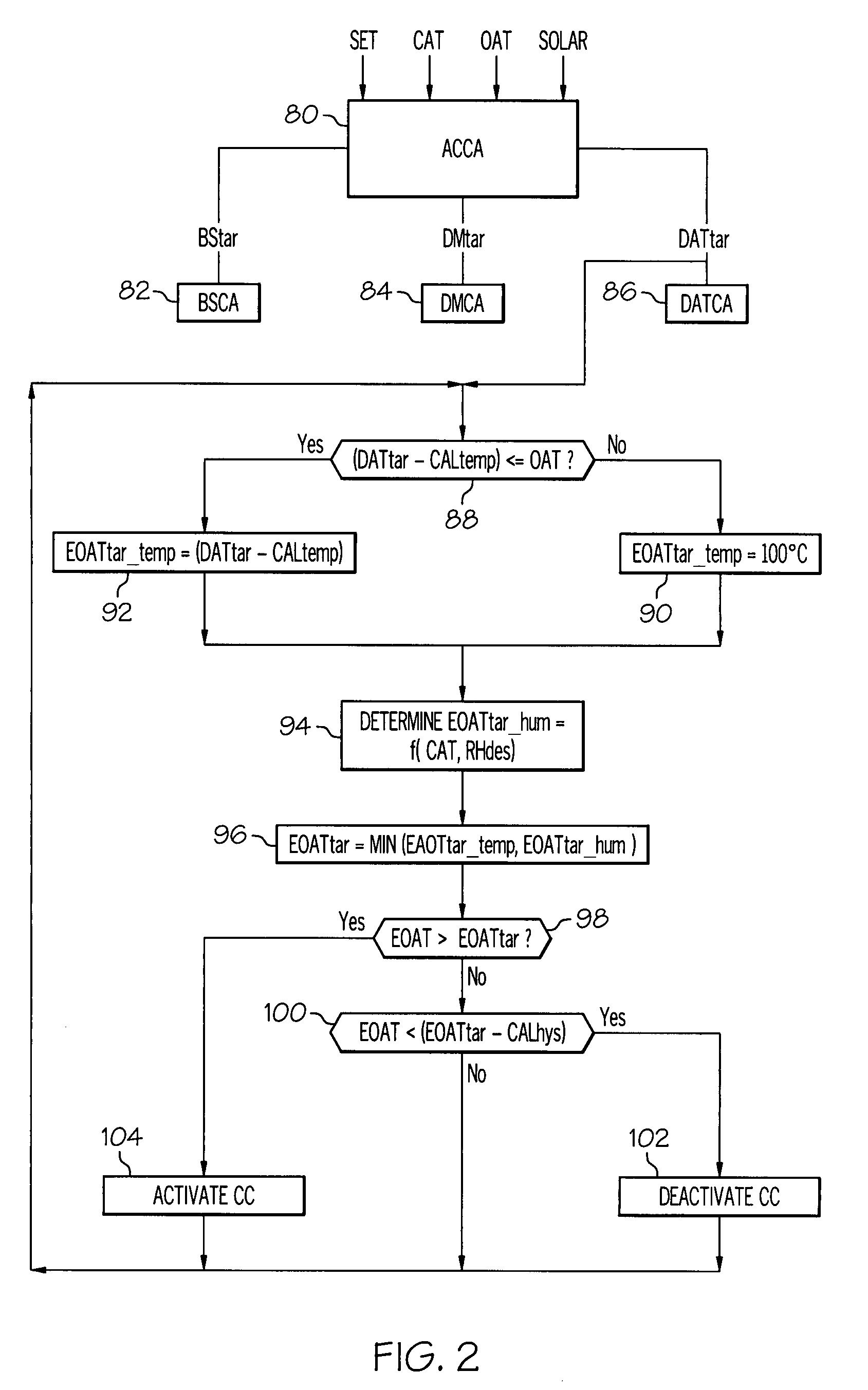

[0007]The present invention recognizes that the fuel efficiency benefits described in the aforementioned U.S. Pat. No. 6,293,116 to Forrest et al. can be achieved at a reduced system cost by combining a pneumatically-controlled variable displacement compressor (such as shown and described in the U.S. Pat. No. 4,428,718 to Skinner, for example) with a compressor clutch cycle control that comes into play when series re-heating of the conditioned air is required to achieve the desired air discharge temperature. The system cost is reduced because a pneumatically-controlled variable displacement compressor is less expensive to produce than an electronically controlled variable displacement compressor, and the control electronics required to carry out the clutch cycling control are simpler and less expensive than with traditional electronically controlled displacement. Ordinarily, of course, a pneumatically-controlled variable displacement compressor is not cycled on and off during activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com