Ammunition supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

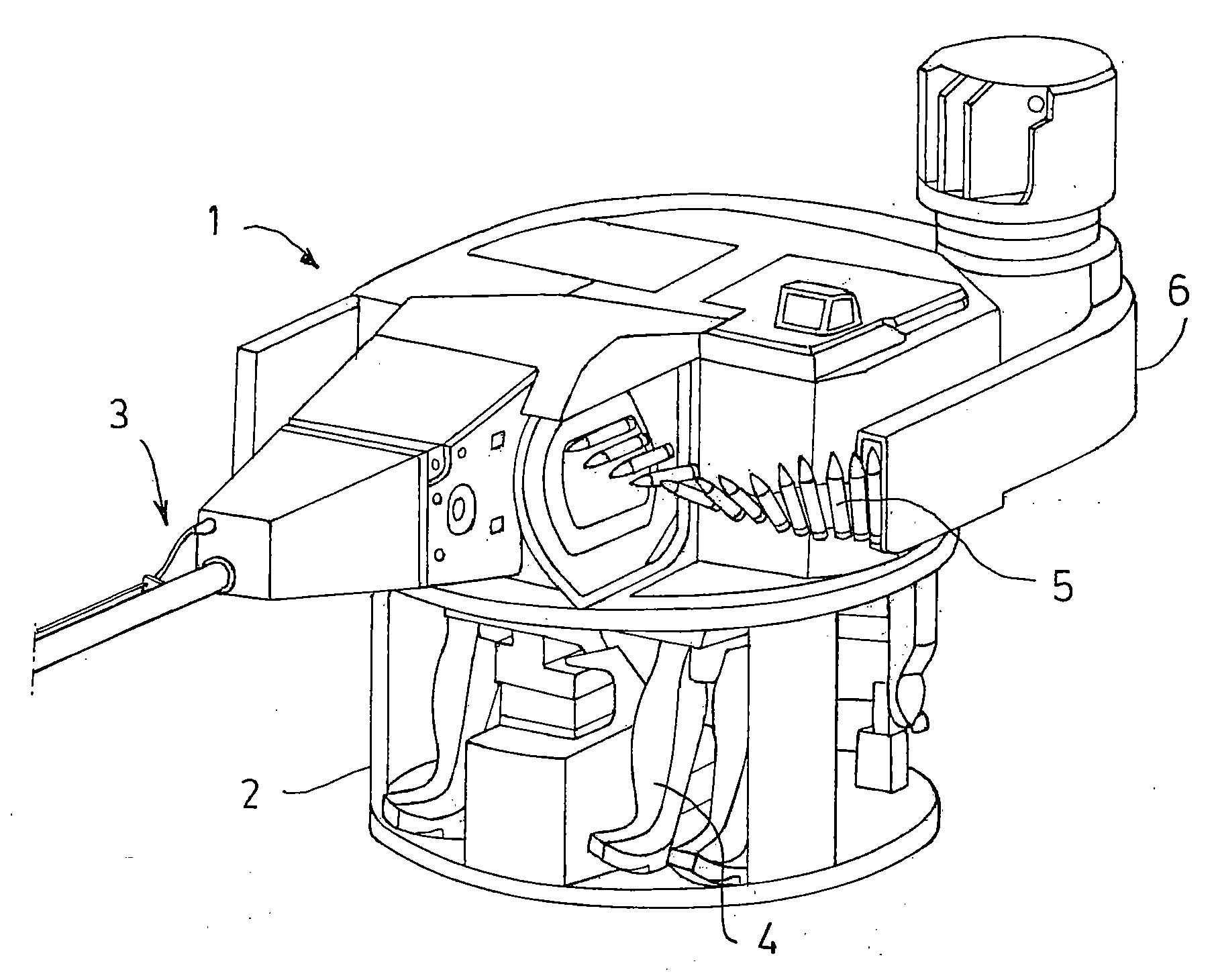

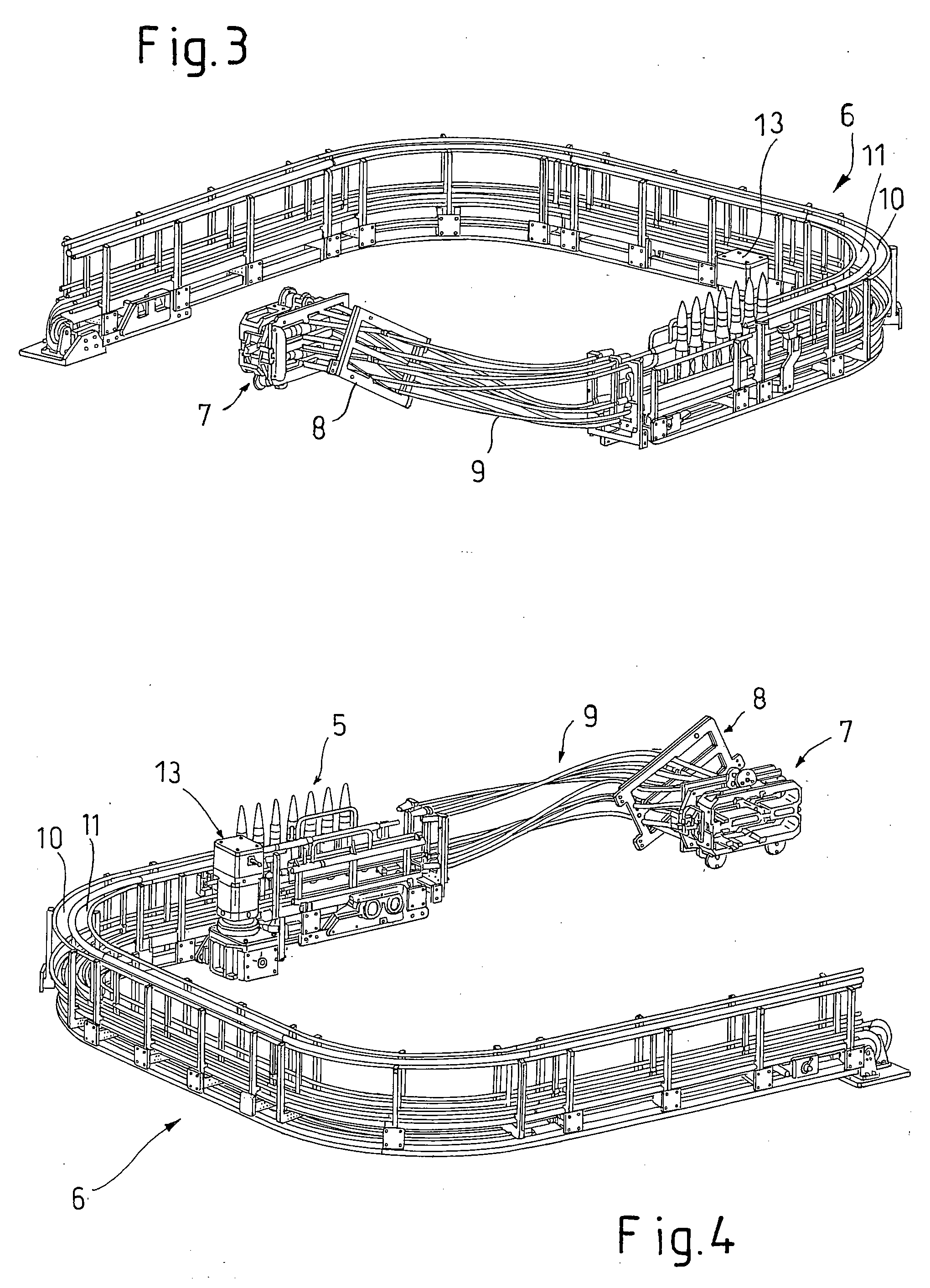

[0024]FIG. 1 shows a turret 1 with a protected cell 2, a weapon system 3, as well as indicated operators 4. Two types of ammunition 5 are fed laterally to the weapon 3. As a rule, there are at least two different types of ammunition that may be fed into the weapon 3. The ammunition 5 is fed to the weapon 3 from an ammunition supply system 6 rotating around the turret 1. The ammunition feed to the weapon takes place in a preferred embodiment by means of a support 7, a torsion apparatus 8, and a manifold 9, which are functionally connected to the ammunition supply system 6 (See FIG. 2).

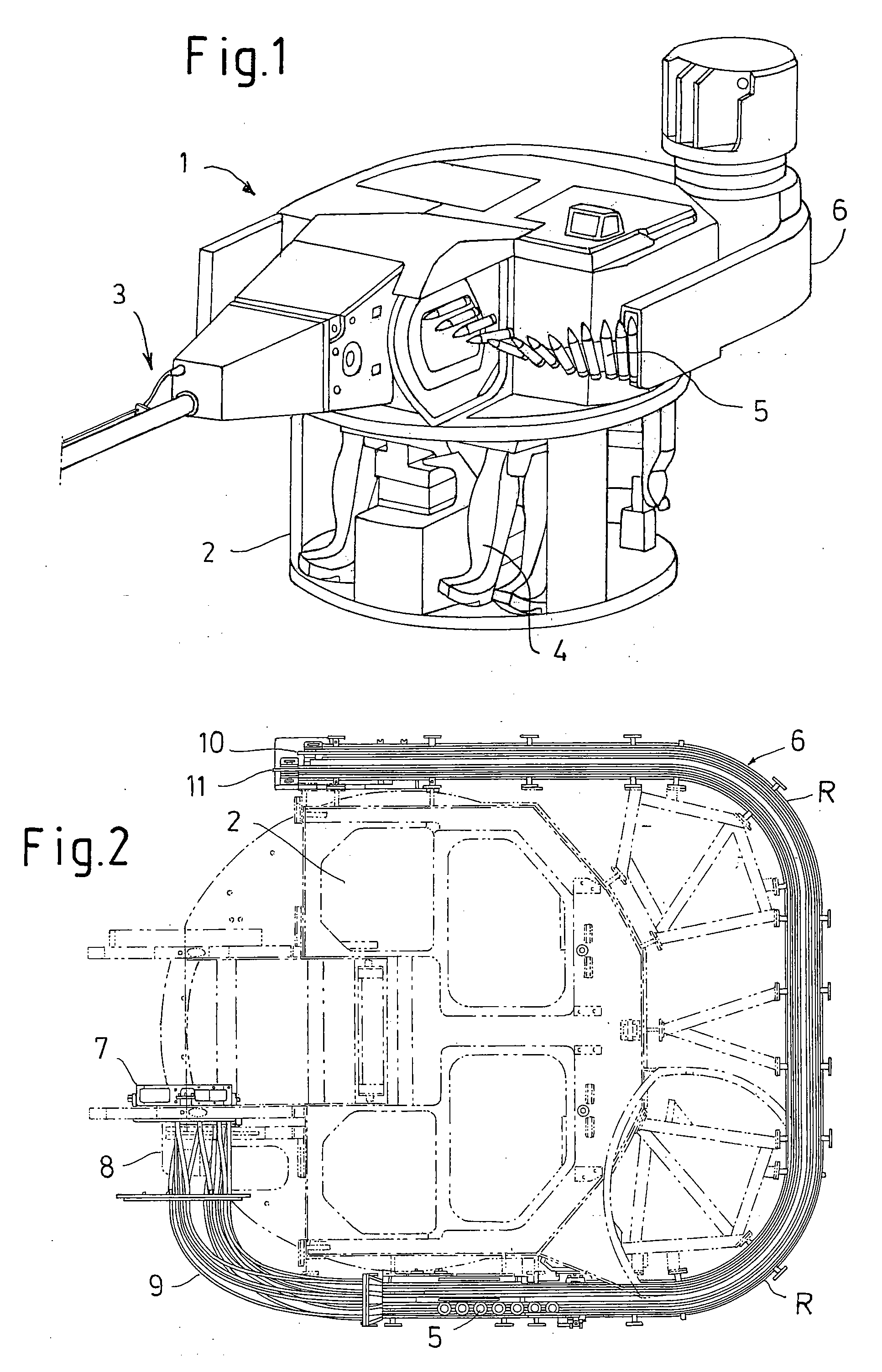

[0025]FIG. 2 shows the turret 1 with the rotating ammunition supply system 6, which is shown in more detail in FIGS. 3 and 4. The ammunition supply system 6 has two ammunition channels 10, 11, in which different types of ammunition are deposited. The transport to the manifold 9 takes place in the preferred embodiment with the aid of a rotating chain 12. The chain 12 is moved by means of an electric driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com