Variable Planing Inflatable Hull System

a technology of inflatable hull and variable planing, which is applied in the direction of special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of loss of efficiency, propulsion systems advantageous to shallow water operations, and ineffective use of existing vessels that use inflatable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

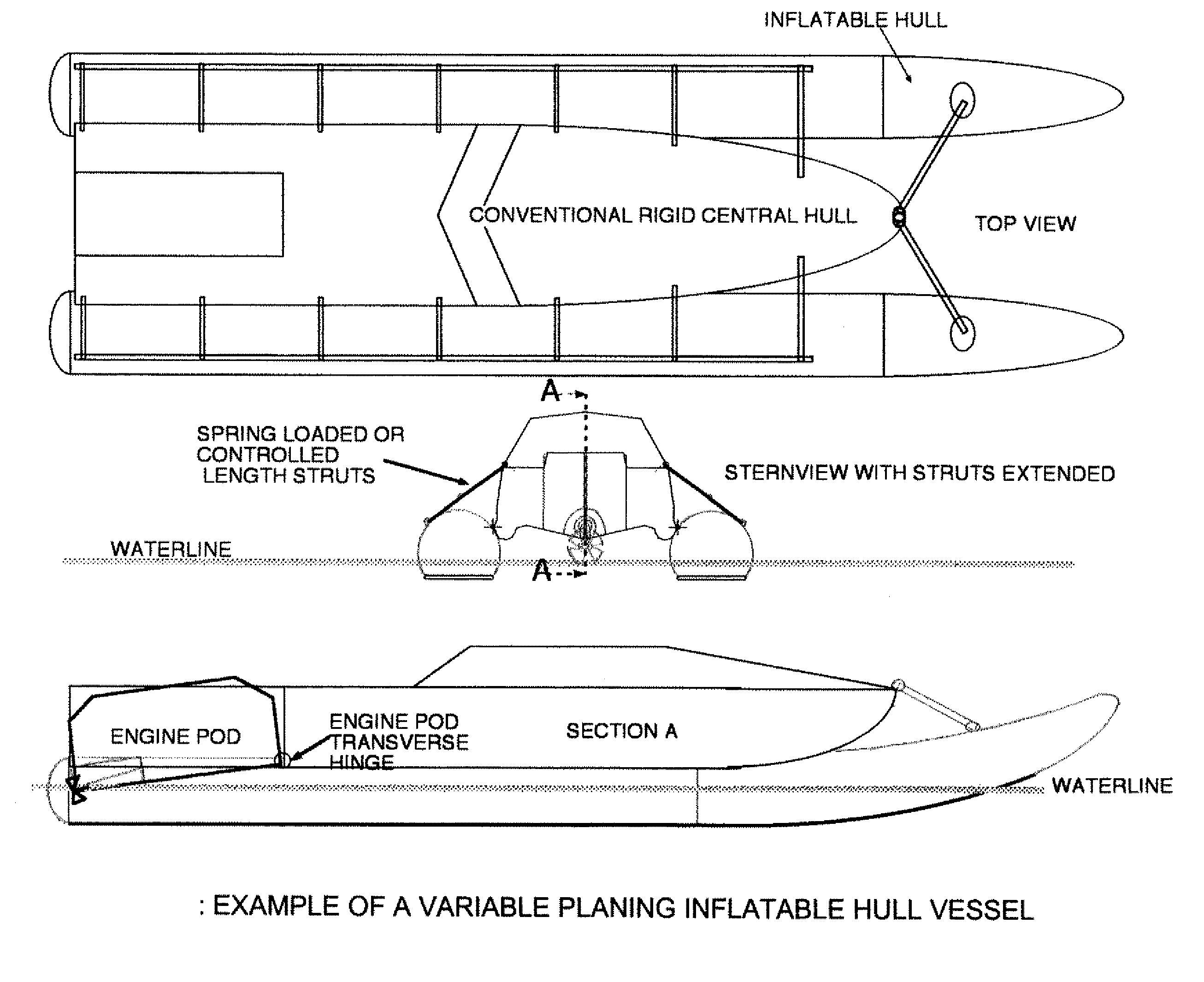

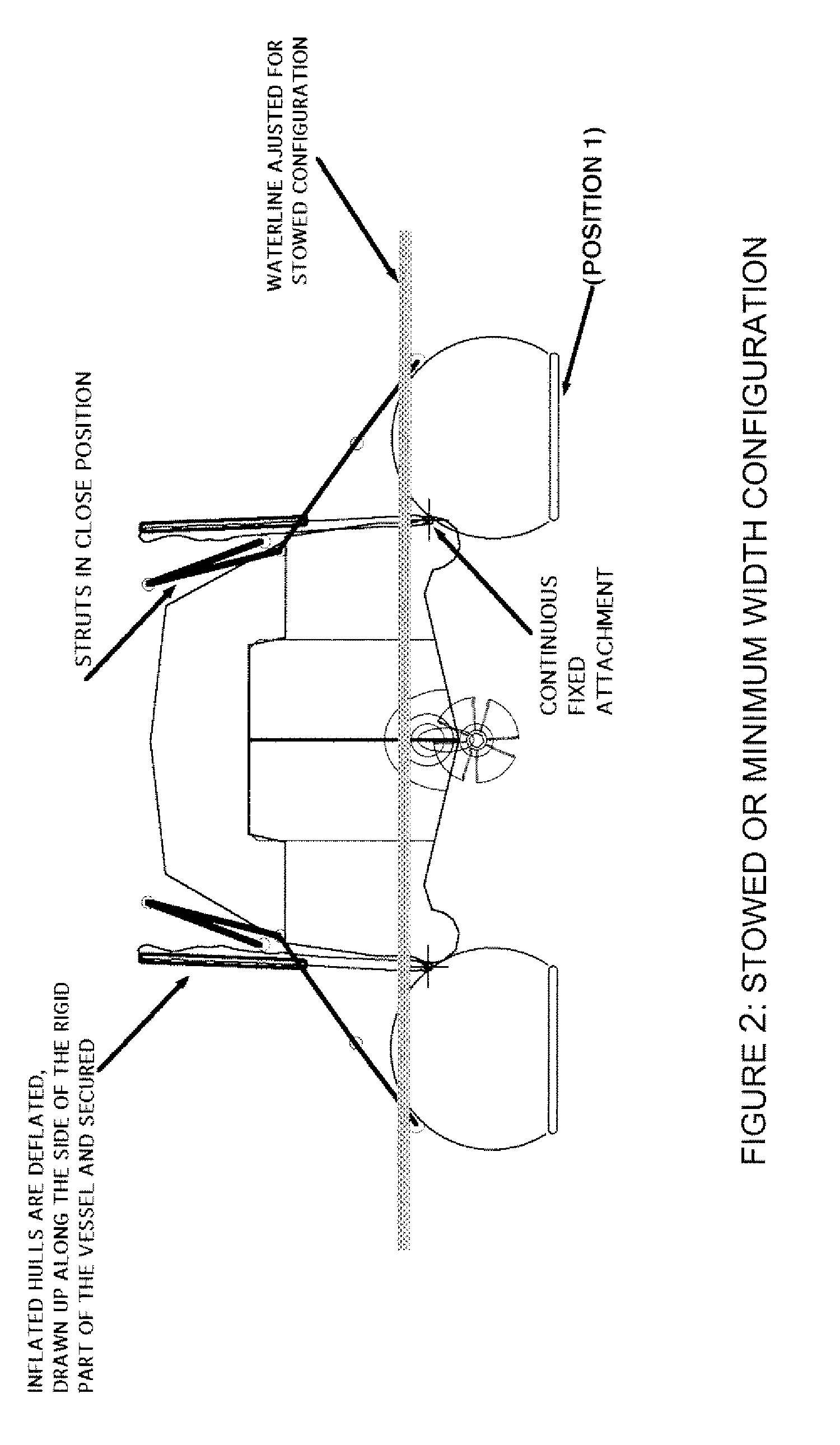

[0016]This invention provides for a vessel that utilizes a variable planing inflatable hull system in order to increase speed, efficiency, acceleration, shock absorption and maneuverability. A hinged engine pod can be added to ensure proper propulsion. The engine pod will itself follow the water surface, assuring that the propeller remains in the water under all operating conditions, but could be withdrawn up against the central hull section when not in use. Such vessel can also reduce its footprint considerably using this technique, so that it can be stowed and shipped in a smaller space. For example, a vessel with a 50′L×17′W×8′H configuration could be reduced to 40′L×9′W×6′H and transported in the cargo hold of a C-130 aircraft.

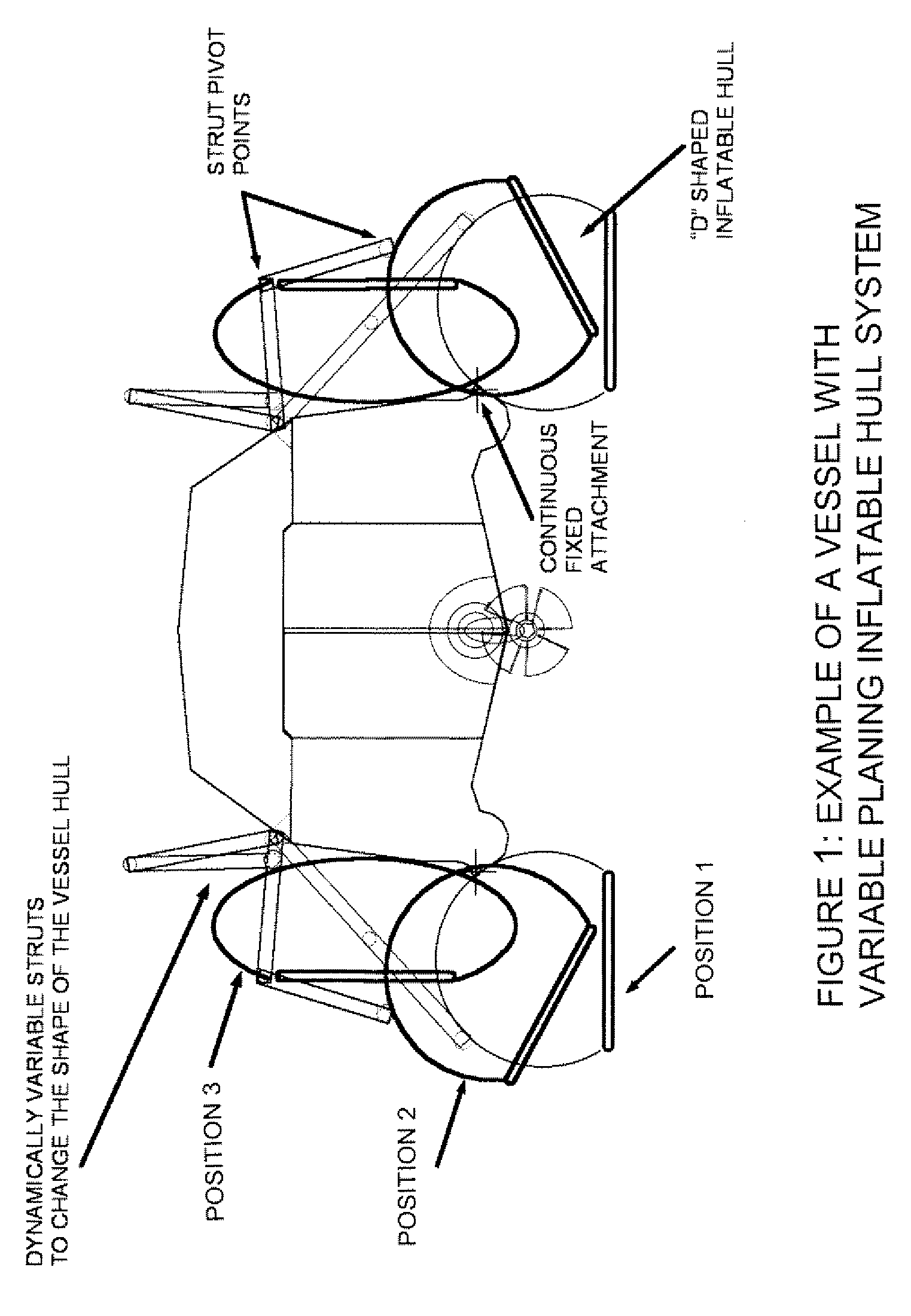

[0017]FIG. 1 shows the “D” shaped inflatable air chambers attached to a more conventional boat hull, typically a rigid (in comparison to the inflatable hull sections) such as may be fabricated of fiberglass or other composite materials or metal. We call th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com