Isothermal vapor chamber and support structure thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The technical characteristics, features and advantages of the present invention will become apparent in the following detailed description of the preferred embodiments with reference to the accompanying drawings. It is noteworthy to point out that the preferred embodiments are used for illustrating the present invention only, but not intended to limit the scope of the present invention.

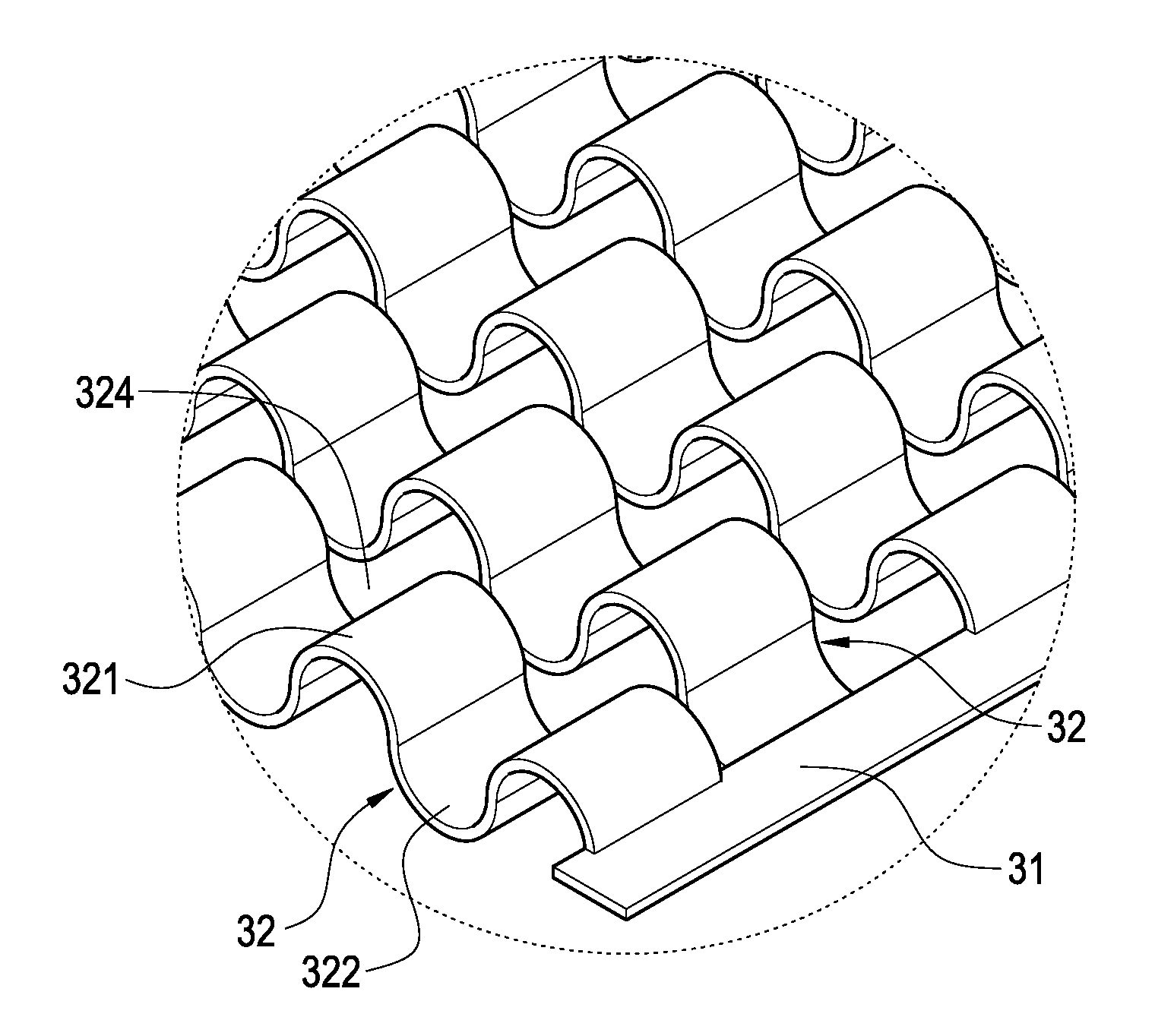

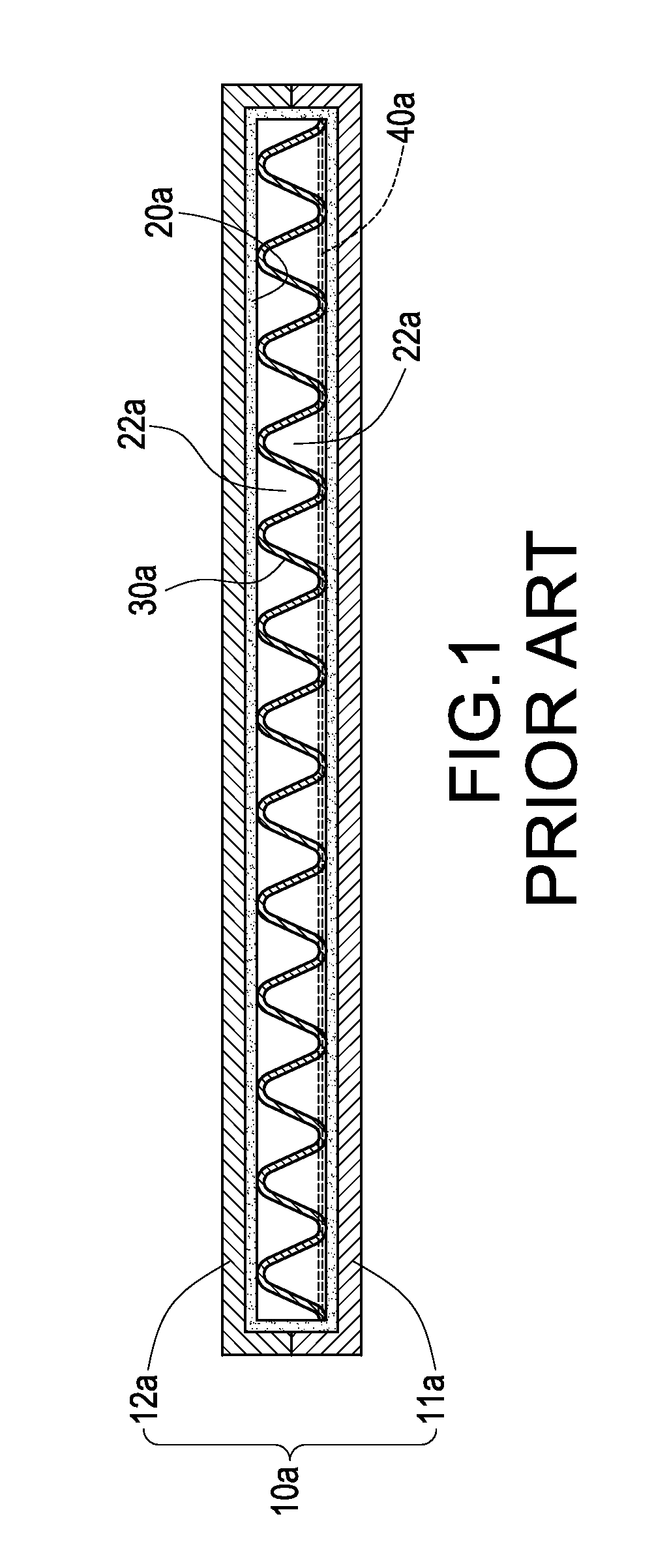

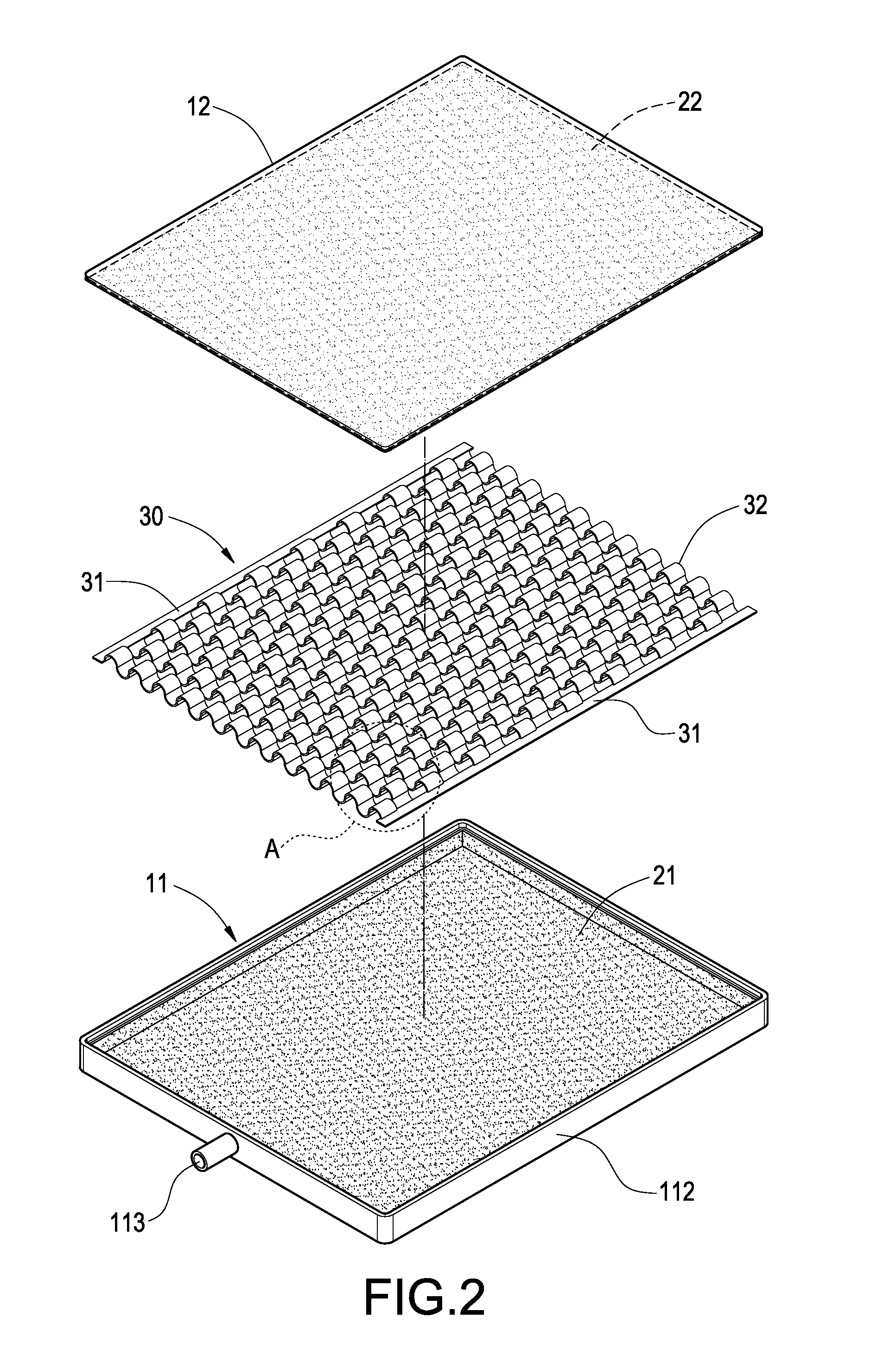

[0025]Referring to FIGS. 2 to 5, the isothermal vapor chamber of the invention is formed by a casing 10, a capillary wick 20, a support structure 30, and a working fluid 40.

[0026]The casing 10 comprises a lower casing panel 11 and an upper casing panel 12 sealed and coupled to the lower casing panel 11, and the lower casing panel 11 is formed by a bottom panel 111 and a plurality of surrounding panels 112 disposed around the periphery of the bottom panel 111, wherein the surrounding panel 112 installs a filling pipe 113 connected both to the interior and exterior of the casing 10.

[0027]The capil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com