Portable bimodal tile saw

a bimodal tile and sawing technology, applied in the field of tools, can solve the problems of imposing a safety hazard on the operator, unsuitable for making precision cuts in large pieces, and limiting the size and shape of tiles that can be cut using such devices, and achieves the effect of convenient transportation and setup, and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

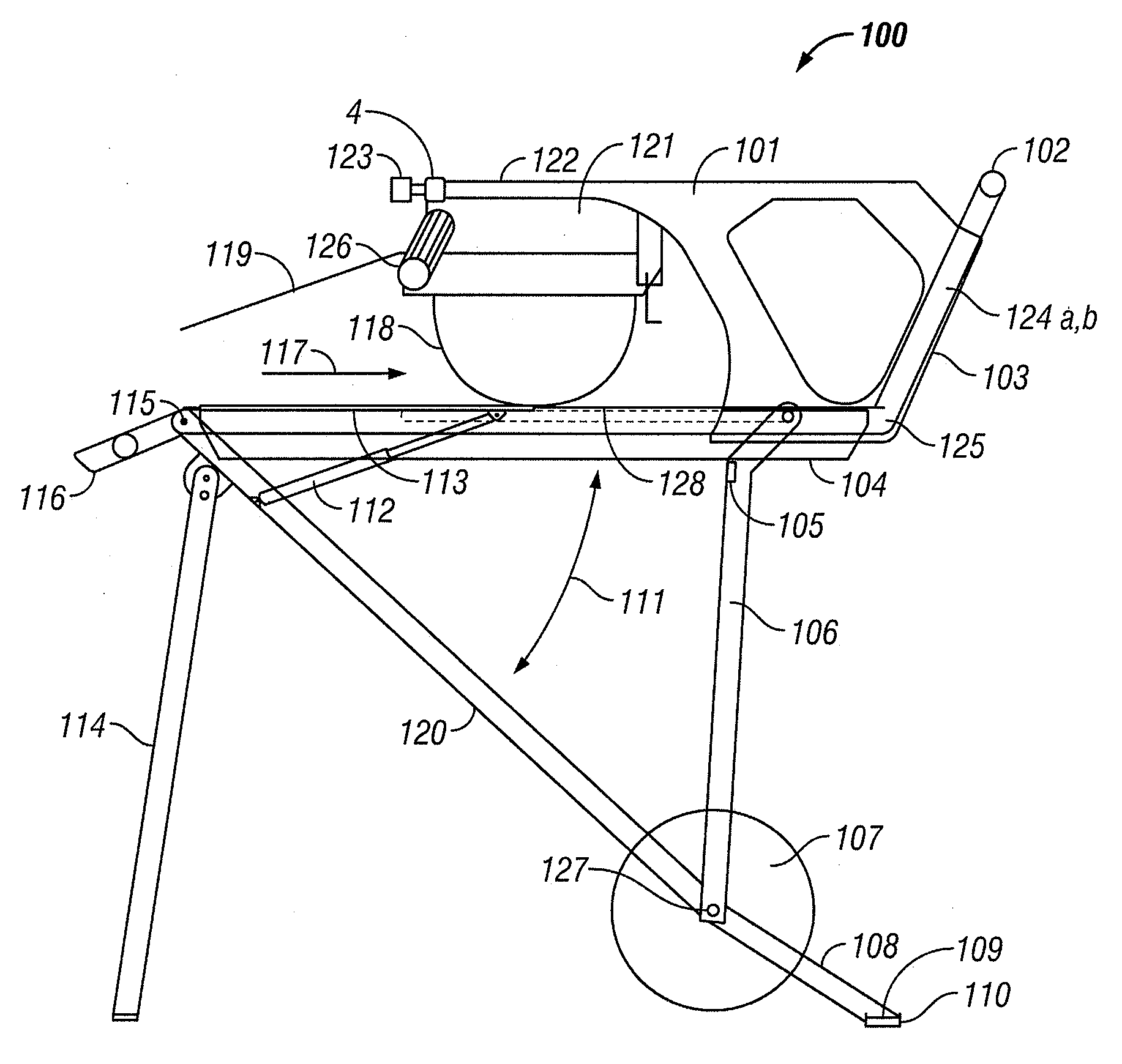

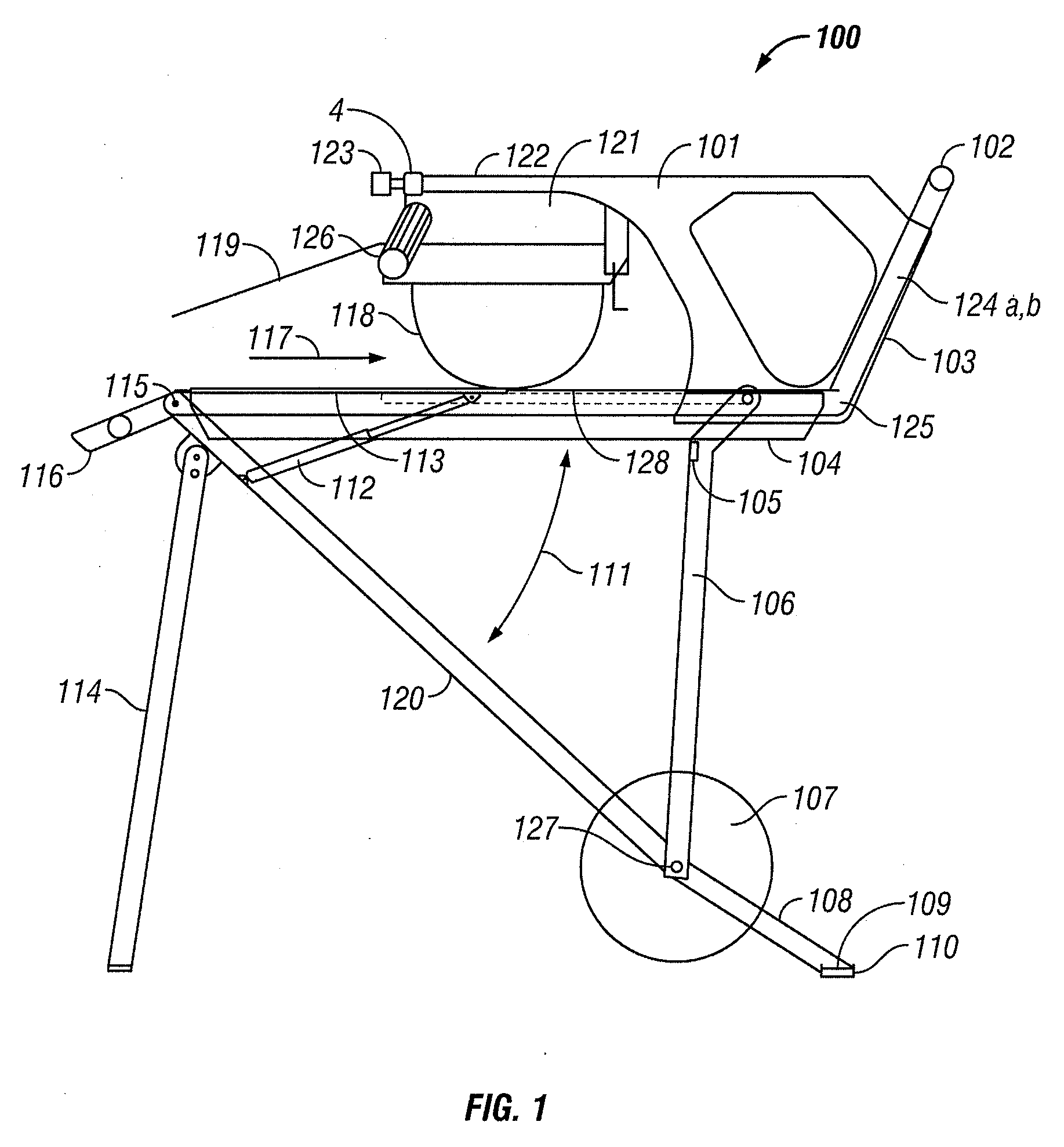

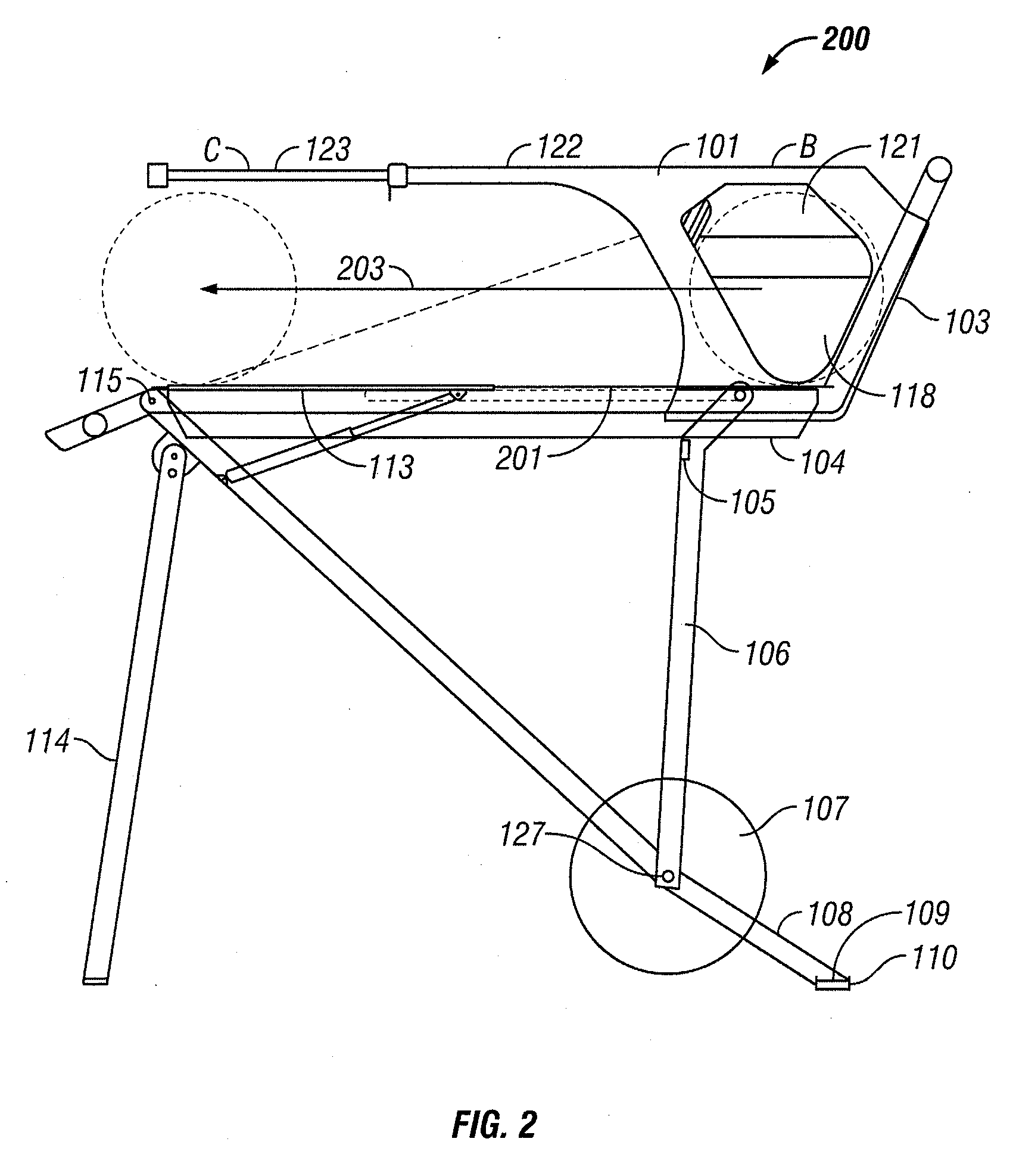

[0024]A bimodal tile saw includes a tray supported on a base extending in a first direction and a water-cooled saw unit suspended from a telescoping arm. Both the tray and the saw unit move relative to the base along the first direction. In a first mode, the saw unit is fixed and the substrate is fed to the saw unit by advancing the tray. In a second mode, the table is fixed and the telescoping arm is advanced using ergonomic handles to bring the blade into contact with the substrate. A laser cutting guide casts a precise beam across the work piece for accurate cutting. An integrated handtruck, having a handle and folding legs actuated by gas pistons allows easy transport and setup of the tile saw. During use, a retractable foot elevates the wheels off of the ground. Water shields protect the saw unit's motor and external environment.

[0025]Referring now to FIG. 1, shown is a view 100 of a portable, bimodal tile saw set up to be used in sliding tray mode. A housing 101 is securely af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap