Insulation kit for hot water boiler

a technology for insulation kits and hot water boilers, which is applied in the direction of fluid heaters, container/bottle construction, rigid containers, etc., can solve the problems of increasing the cost of heating oil, joints that are known to open, and plastic-based materials that shrink with tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

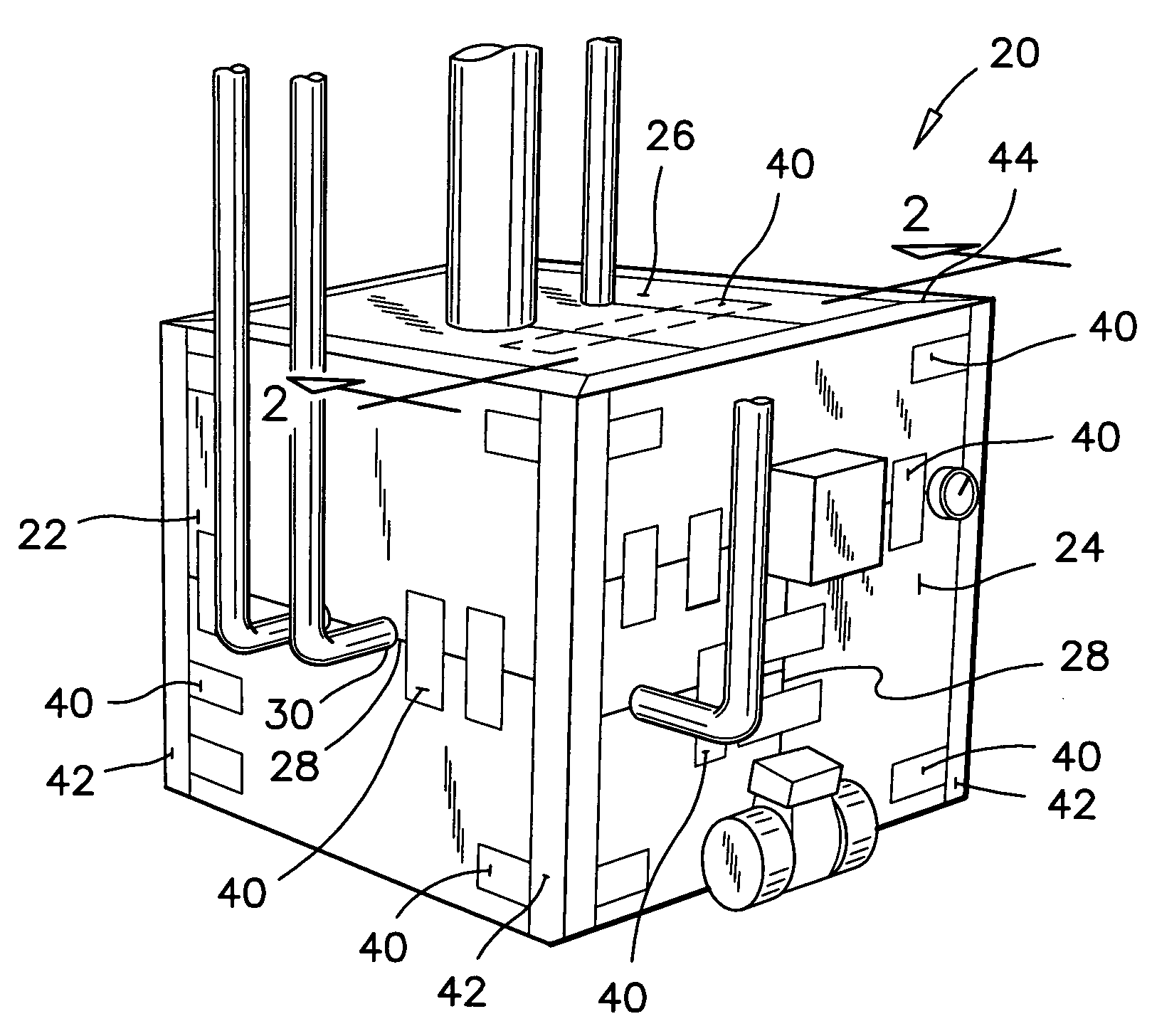

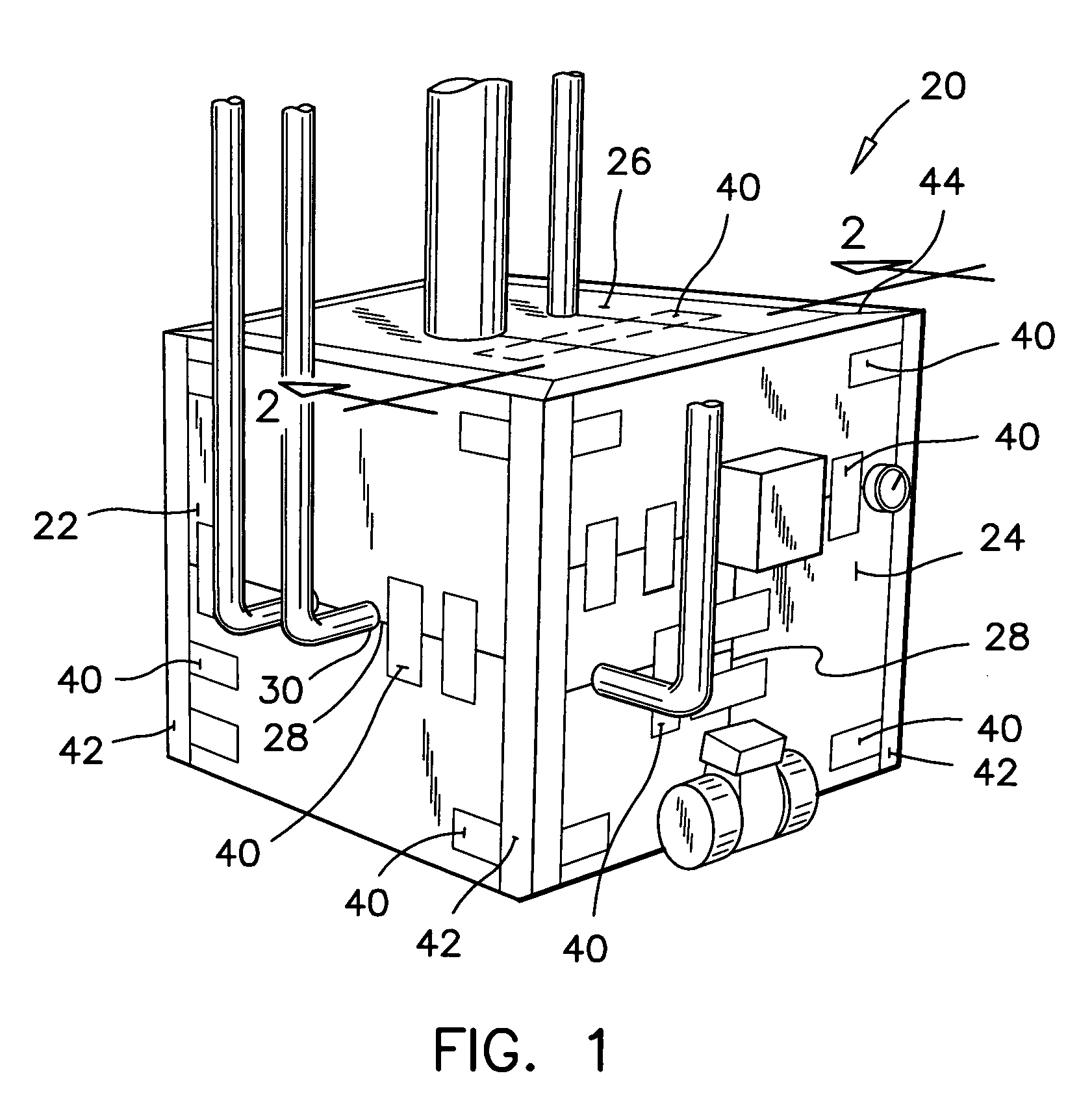

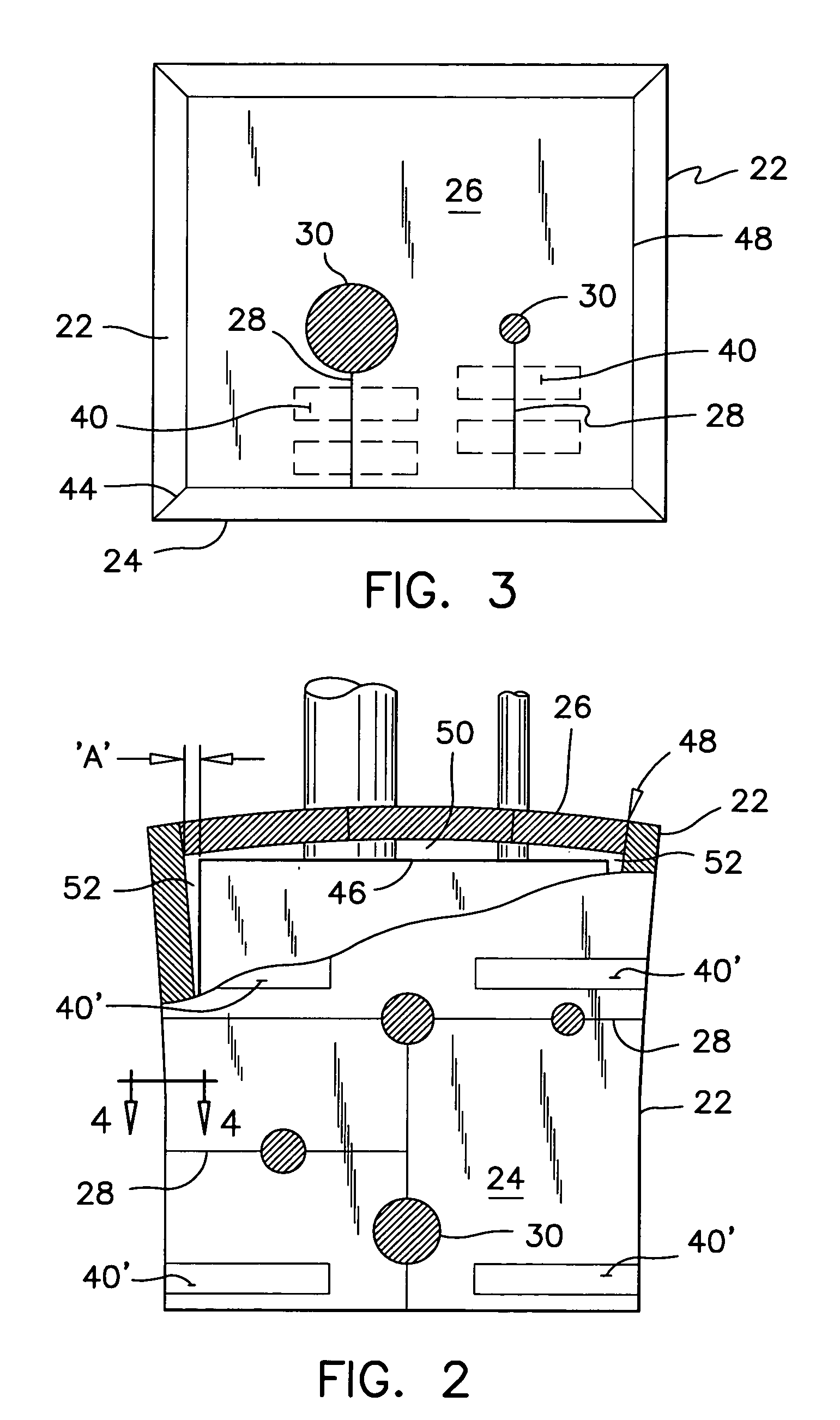

[0023]Referring firstly to FIG. 1, the preferred insulation kit 20 is made of two side panels 22, two end panels 24 and a top panel 26. The side, end and top panels have dimensions for enclosing a hot water boiler completely. Preferably, the top panel 26 is removable to allow a serviceman to periodically remove a cover plate on the boiler and to clean soot from the plenum of the boiler for example.

[0024]The side, end and top panels 22, 24, 26 have slits 28 therein and openings 30 along these slits, for enclosing pipes and instruments that are associated with a hot water boiler. Therefore these panels are made in two or more sections that are assembled together as a kit. All openings 30 have dimensions for tight-fit mounting around the pipes and instruments passing there through.

[0025]The panels are joined to each other at corner joints where the joint makes a right angle, and straight joints extending within a plane of a panel. The slits 28 are also referred to as straight joints.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com