Phase-change composite granular material, preparation method and application thereof and battery heat sink

A technology of phase-change composite materials and heat dissipation devices, which is applied in the field of phase-change composite material pellets and its preparation, and battery heat dissipation devices. It can solve problems such as damage, short circuit, and high porosity of electronic devices, and achieve the effect of prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

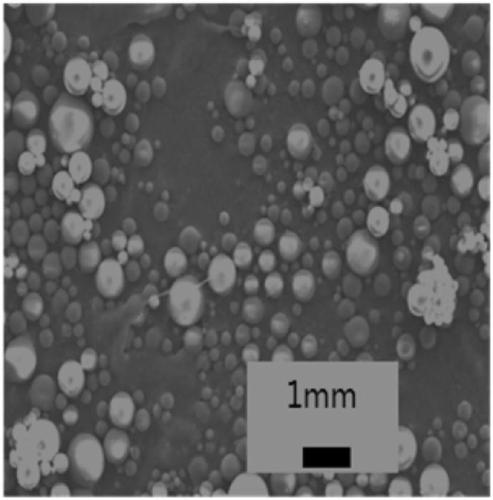

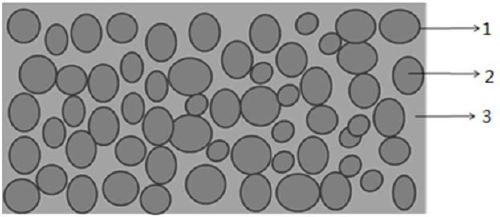

[0024] According to the first aspect of the present invention, the present invention provides a kind of preparation method of phase change composite material pellet, and this method comprises:

[0025] 1) impregnating the porous media matrix with liquid-solid phase change materials to obtain porous composite materials;

[0026] 2) granulating the porous composite material to obtain porous composite material pellets;

[0027] 3) Coating the porous composite pellets with an insulating resin to form an insulating layer on the surface of the pellets.

[0028] In the present invention, the porous medium matrix enables the liquid-solid phase change material to maintain a solid shape in appearance when the phase change occurs, and it can be a carrier commonly used in the preparation of shape-stable phase change materials (FSPCM), from the type of material The upper part can be selected from porous inorganic matrix, porous organic matrix and porous metal matrix. For the present inve...

Embodiment approach

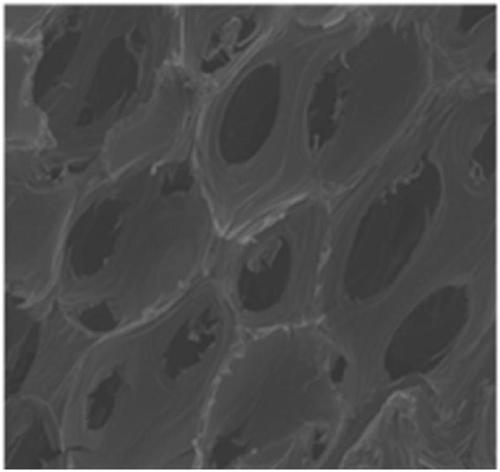

[0031] In the present invention, the porous carbon material can be prepared by self-foaming or foaming in the presence of a foaming agent using pitch or a mixture of pitch and graphite as a raw material, followed by carbonization and graphitization in sequence. According to a specific embodiment, the porous carbon material is prepared by the following method:

[0032] a) Add pitch to the autoclave, raise the temperature to 200-500°C under the pressure of 0-10MPa, preferably 3-8MPa, keep the pressure at constant temperature for 0.1-5h, and then cool;

[0033] b) Put the product obtained in step 1) into a carbonization furnace, raise the temperature to 500-1600°C, keep the temperature constant for 0.1-2h, and then cool to obtain a carbonized product;

[0034] c) Put the carbonized product into a graphitization furnace, raise the temperature to 2000-2800°C, keep the temperature constant for 0.1-1h, and then cool to obtain porous carbon.

[0035] In steps a)-c), the cooling tempe...

preparation example

[0068] This preparation example is used to illustrate the preparation methods of the porous carbons of the examples and comparative examples.

[0069] Put the mesophase pitch (the softening point is 300°C, the residual carbon rate is 85wt%) into the autoclave, and under the pressure of 5MPa, the temperature is raised to 500°C at a heating rate of 5°C / min, and the pressure is maintained for 30min, and then the temperature is lowered to room temperature. The obtained product was put into a carbonization furnace at a heating rate of 5°C / h to 1200°C, kept at a constant temperature for 0.5 hours, and then cooled to below 40°C to obtain a carbonized product. Put the carbonized product into a graphitization furnace at a heating rate of 300°C / h to 2500°C, and keep the temperature constant for 0.5h. After the constant temperature is completed, it is naturally cooled to below 50°C and then released from the furnace to obtain porous carbon. The density of the porous carbon is 0.5g / cm 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com