Chemical barrier fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0076]Referring to FIG. 11a, a known polypropylene co-polymer film 48 of thickness 30 microns was tested in its unprocessed state for permeation of ammonia solution using test method EN 369: 1993. The breakthrough time was 8 minutes.

example 2

[0077]A known co-extruded polymer film 46a of total thickness 40 microns is shown in FIG. 11b. This film 46a comprises a 4 microns thick core layer 50 of EVOH bonded by means of tie layers (not shown) to first 52a and second 52b outer polypropylene co-polymer layers 14 microns thick. This film 46a was tested in its unprocessed state for permeation of a 35% ammonia solution as for Example 1. The breakthrough time for this film was 21 minutes.

example 3

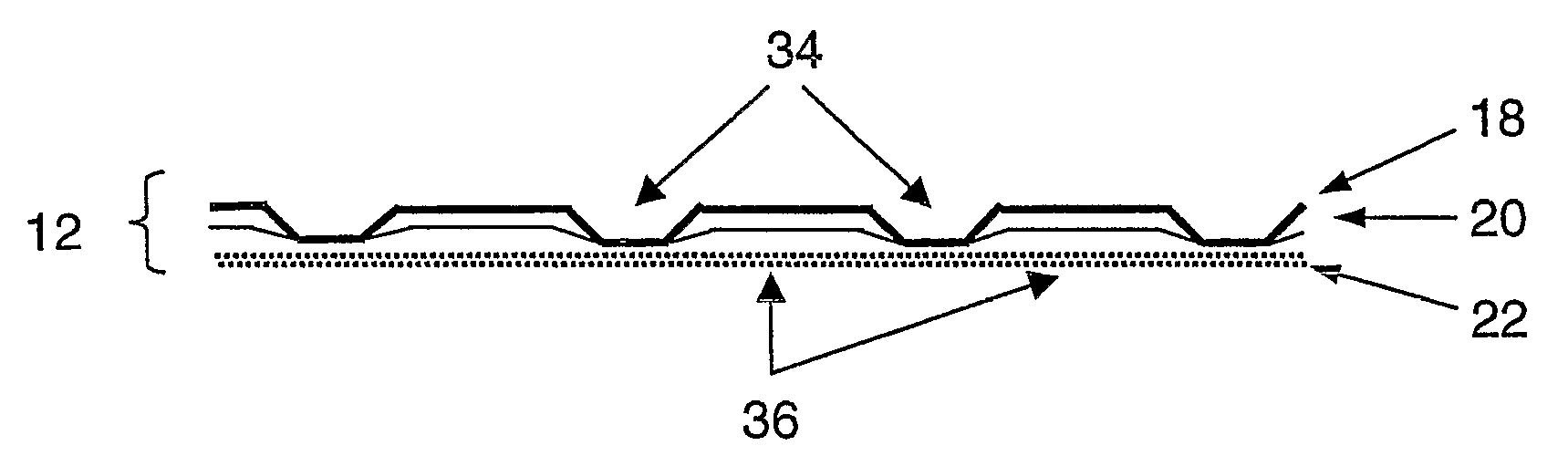

[0078]The 30 microns polypropylene co-polymer film 48 of Example 1 and the co-extruded polymer 46a film of Example 2 were bonded together with a 40 g / m2 basis weight polypropylene spunbonded non-woven fabric 58 using thermal point-bonding in a single calender bonding lamination step. The resultant chemical barrier fabric 12 thus comprised a 30 microns polypropylene co-polymer film forming the upper layer 18 (and upper surface 38) of the fabric, a non-woven layer 58 forming the lower layer 22 (and lower surface 40) of the fabric, and a co-extruded film layer disposed therebetween forming the middle layer 20 of the fabric. This fabric structure is shown in FIG. 11c.

[0079]The diamond point-bond pattern of FIG. 10 was utilised in the manufacture of this chemical barrier fabric 12, giving a point-bond area of substantially 19% of the surface of the fabric. Approximately 81% of the area of the fabric surface was un-bonded. The extent of the bonding between the component layers 18, 20 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap