Trench shield with adjustable vertical panels

a vertical panel and shielding unit technology, applied in the direction of shaft equipment, shaft lining, artificial islands, etc., can solve the problems that none of these systems is able to accommodate easily and quickly unplanned obstructions, and achieve the effect of restricting the twisting or torque of the panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

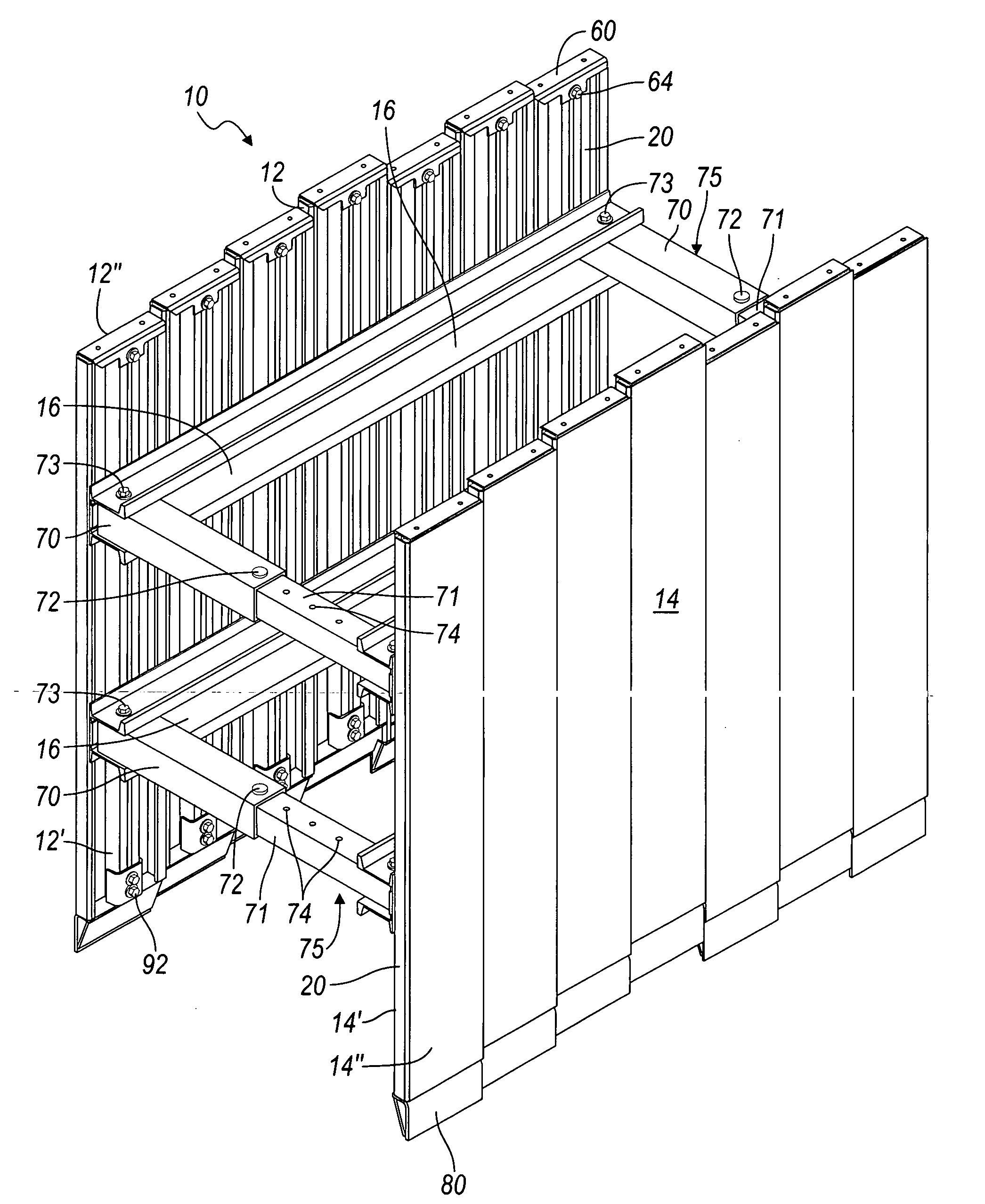

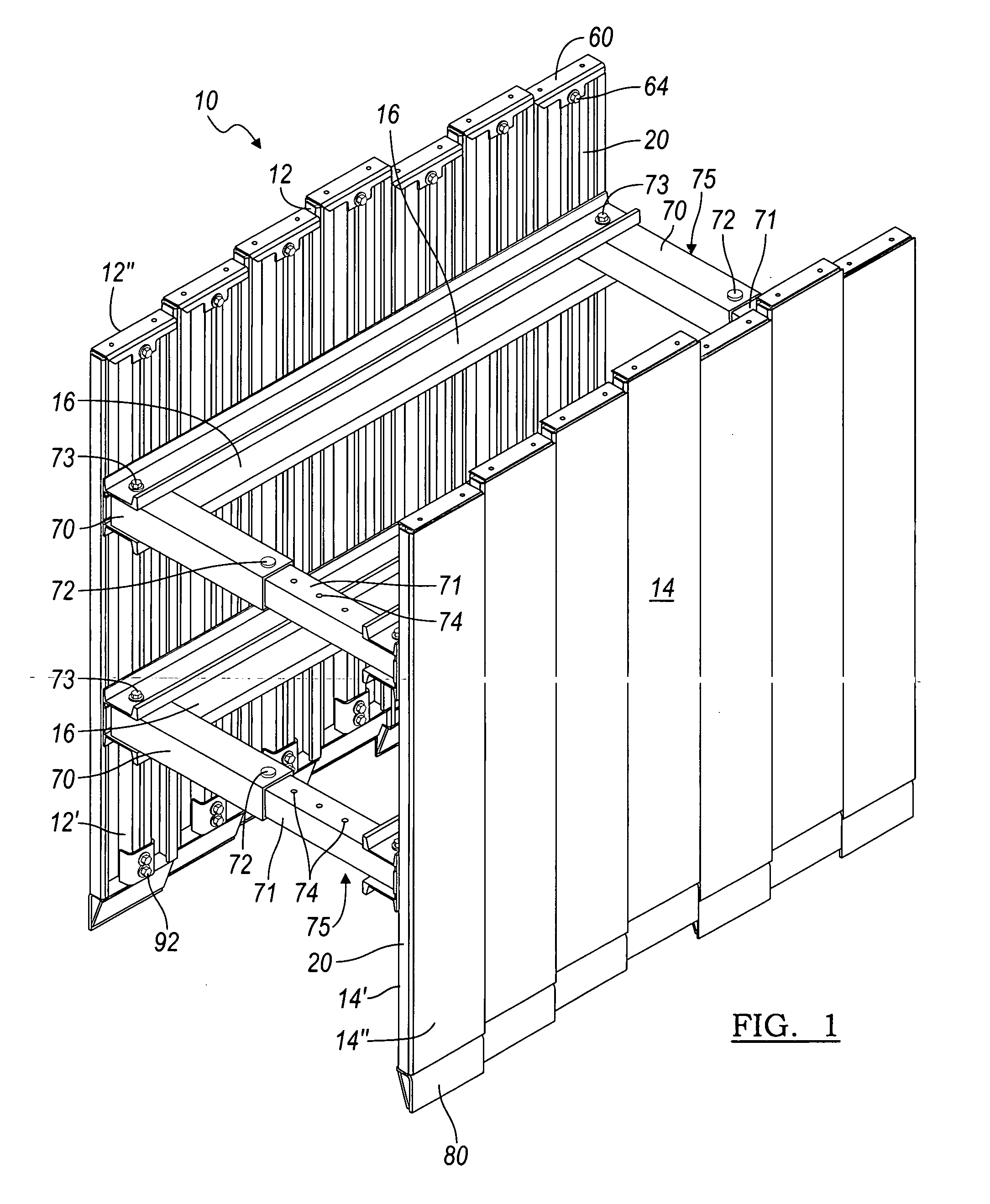

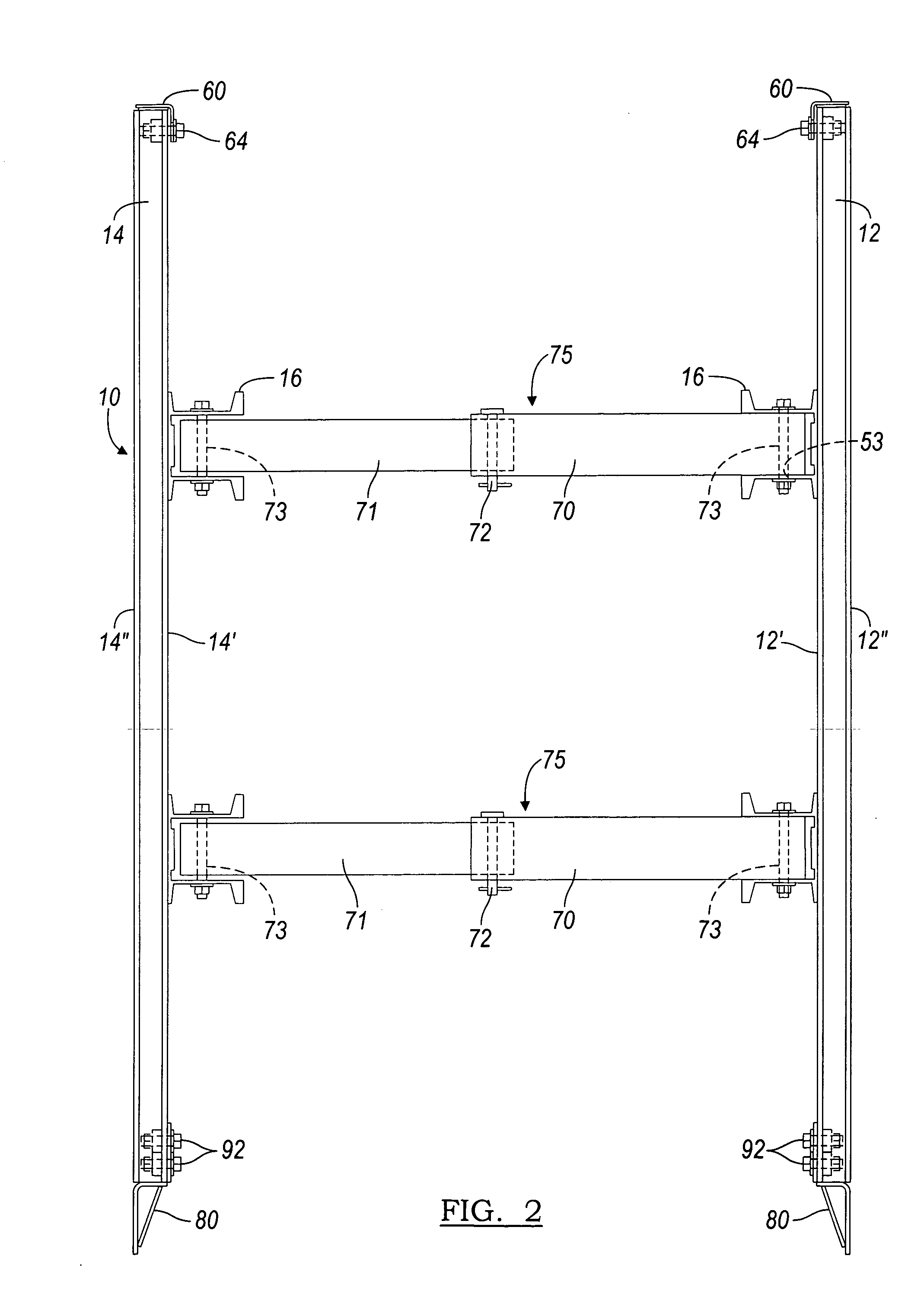

[0029]Referring to FIGS. 1 and 7, a trench shielding unit 10 includes opposing first and second sidewalls 12, 14, with each sidewall having an inside face 12′, 14′ and an outside face 12″, 14.″ Each sidewall 12, 14 includes a plurality of vertical panels 20, each panel having a height and opposing concave and convex side edges 28, 29, respectively, which extend along the full height of the panel for inter-engaging with its adjacent panels. Each vertical panel 20 also includes a C-shaped channel 26 having a constant width traversing the panel's height at its center.

[0030]As shown in FIG. 5, two longitudinal beams 16, also known as whalers, each of which traverses the length of the trench unit 10 along an inside face 12′, 14′ of a sidewall 12, 14, are each secured to each panel 20 of the respective sidewall 12, 14. Each whaler 16 has a U-shaped cross section, as shown in FIG. 8. Each panel 20 is secured to each corresponding whaler 16 by a clamp-like fastener 42, which includes a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com