Production Of Chain Agglomerations Of Nano-Scale Metal Particles

a technology of nano-scale metal particles and chain aggregations, which is applied in the direction of metal/metal-oxide/metal-hydroxide catalysts, physical/chemical process catalysts, instruments, etc., can solve the problem of difficult and expensive process operation, inability to meet the requirements of bianchini methods, etc. problem, to achieve the effect of facilitating the flow of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

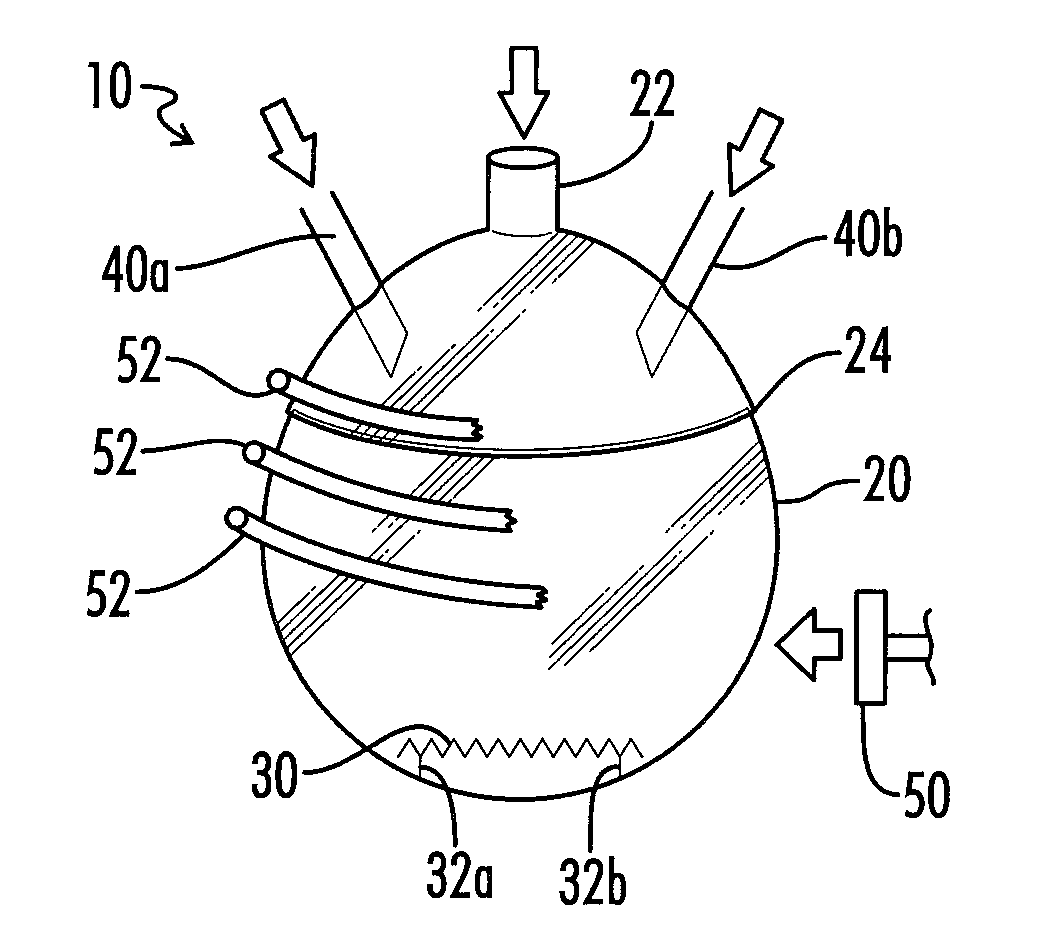

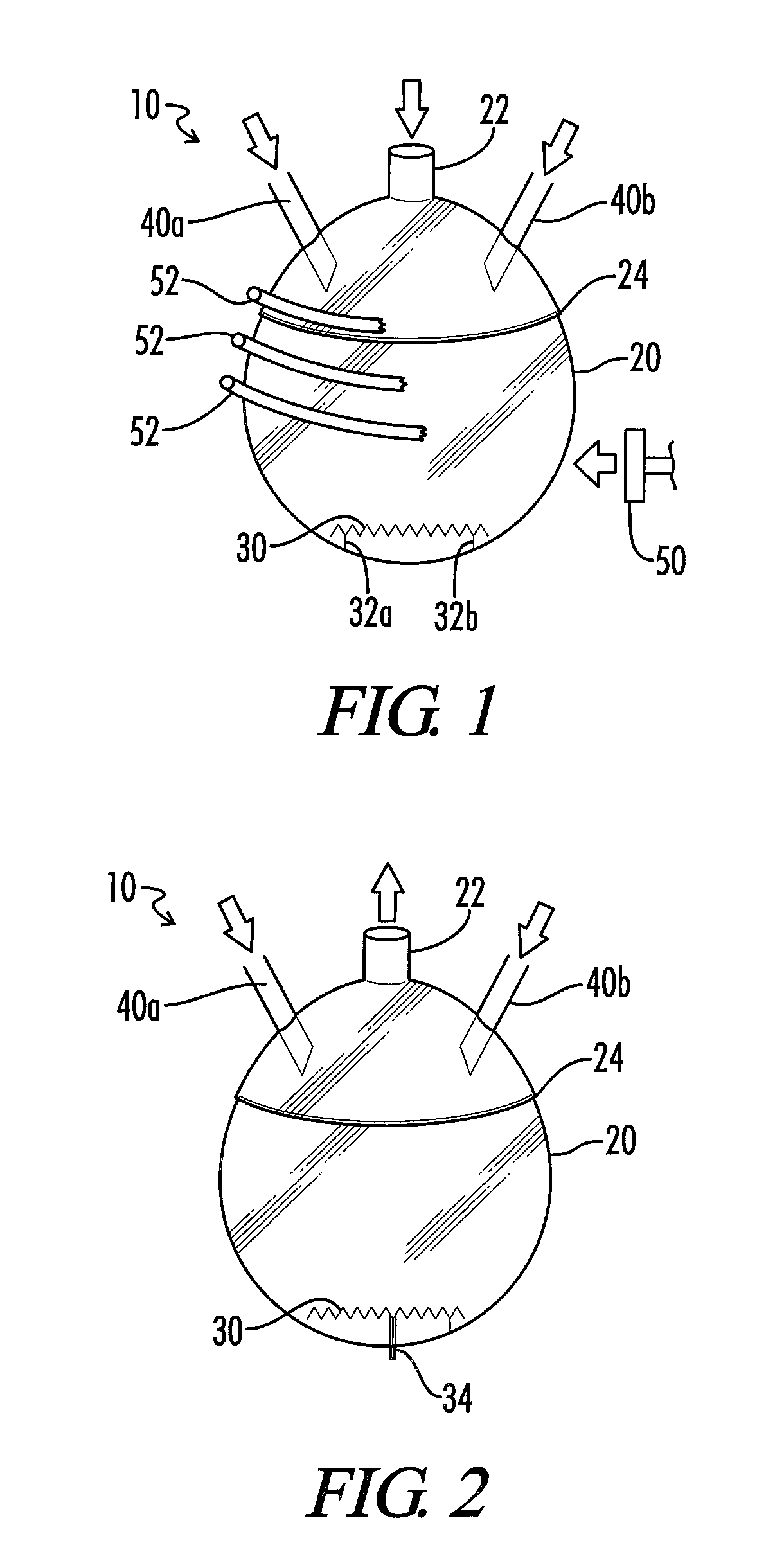

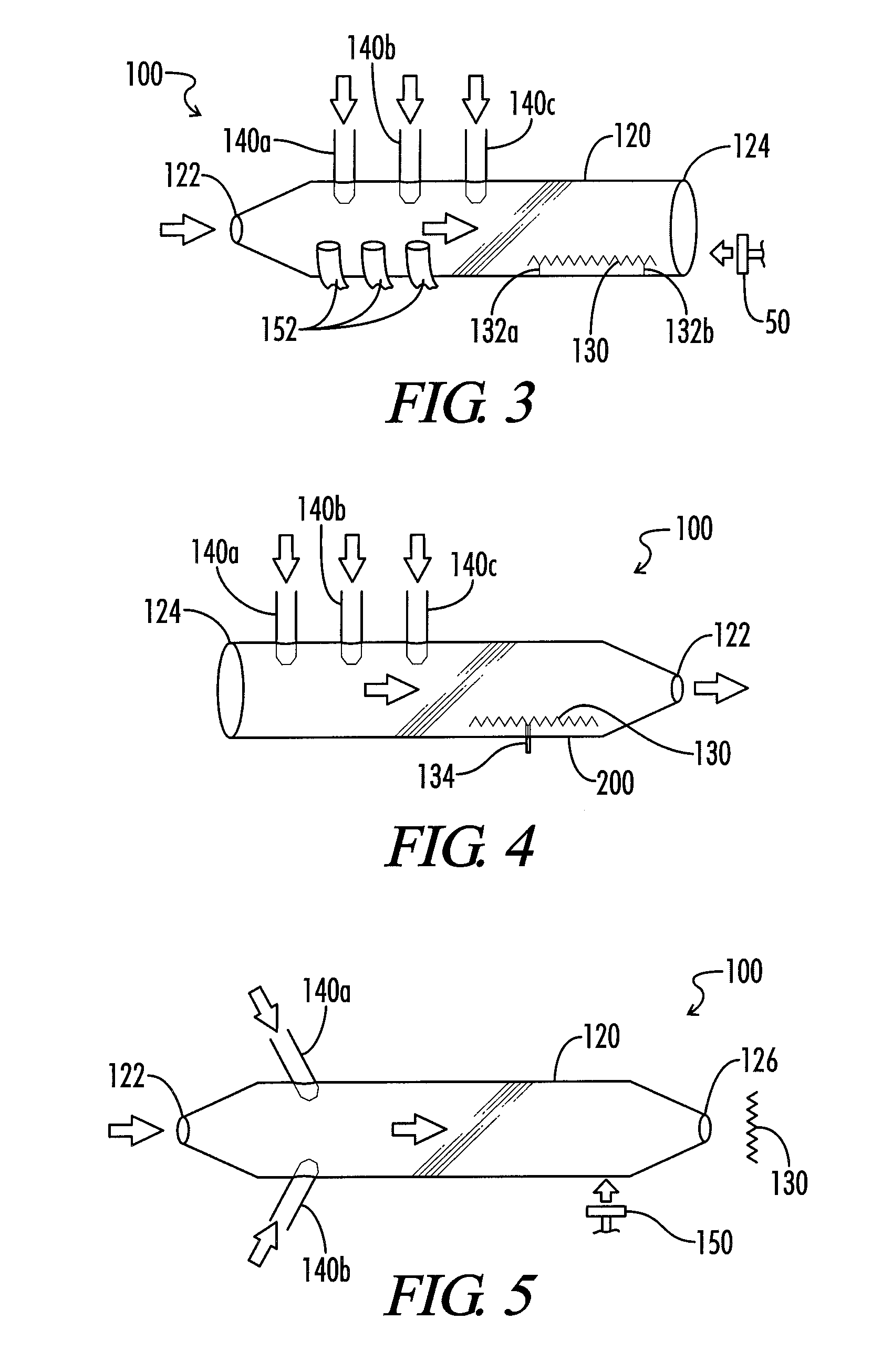

[0055]Referring now to the drawings, an apparatus in which the inventive process for the production of nano-scale metal particles can be practiced is generally designated by the numeral 10 or 100. In FIGS. 1 and 2 apparatus 10 is a closed system comprising closed reactor vessel 20 whereas in FIGS. 3-5 apparatus 100 is a flow-through reaction apparatus comprising flow-through reactor vessel 120.

[0056]It will be noted that FIGS. 1-5 show apparatus 10, 100 in a certain orientation. However, it will be recognized that other orientations are equally applicable for apparatus 10, 100. For instance, when under vacuum, reactor vessel 20 can be in any orientation for effectiveness. Likewise, in flow-through reactor vessel 120, the flow of inert carrier gas and decomposable moieties or the flow of decomposable moieties as drawn by a vacuum in FIGS. 3-5 can be in any particular direction or orientation and still be effective. In addition, the terms “up”“down”“right” and “left” as used herein re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com