Hazardous drywall remediation method and system

a remediation method and remediation system technology, applied in the field of hazardous drywall remediation methods and systems, can solve the problems of occupants of the structure, sulfide gas that smells like rotten eggs, emits hazardous gas,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

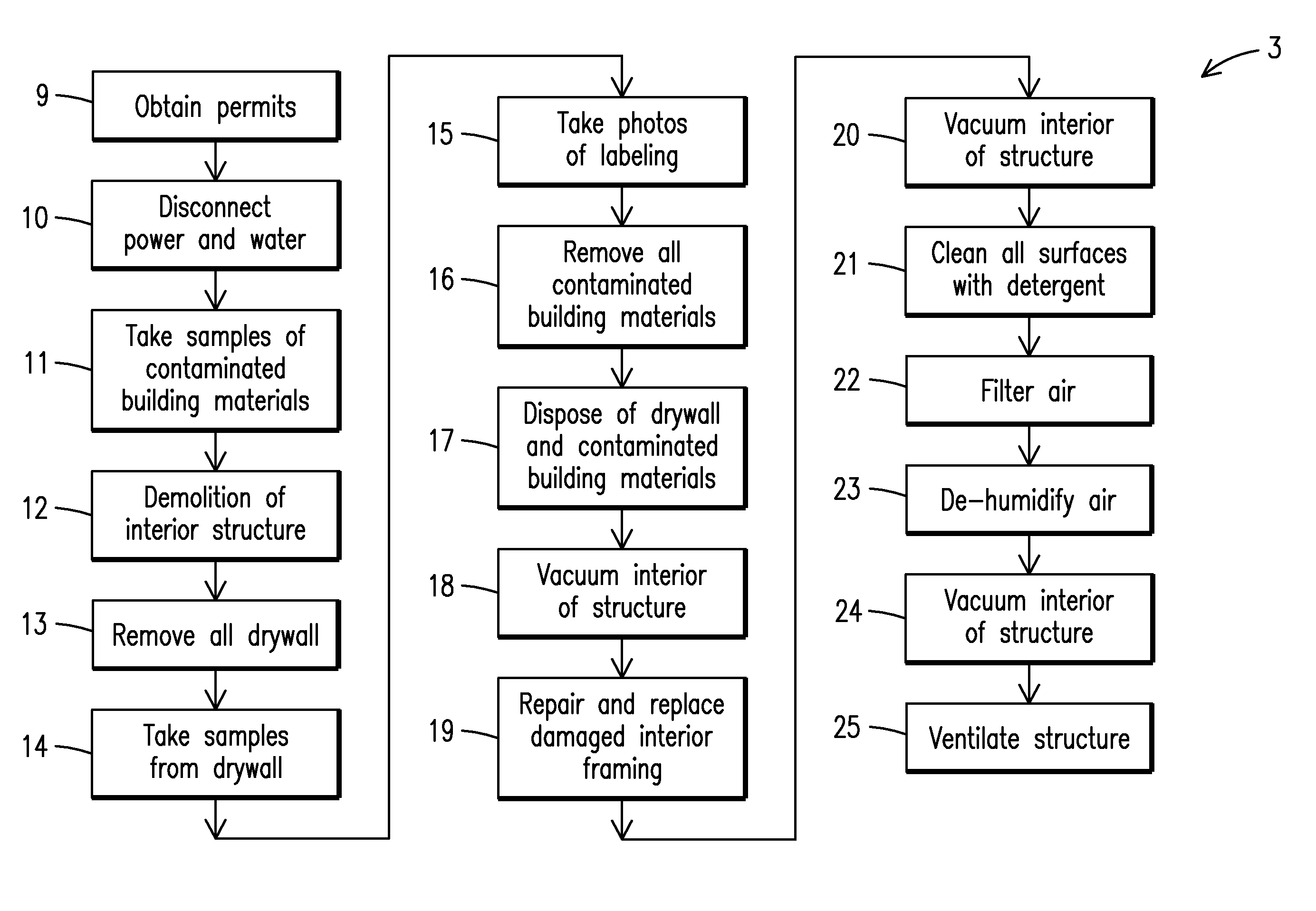

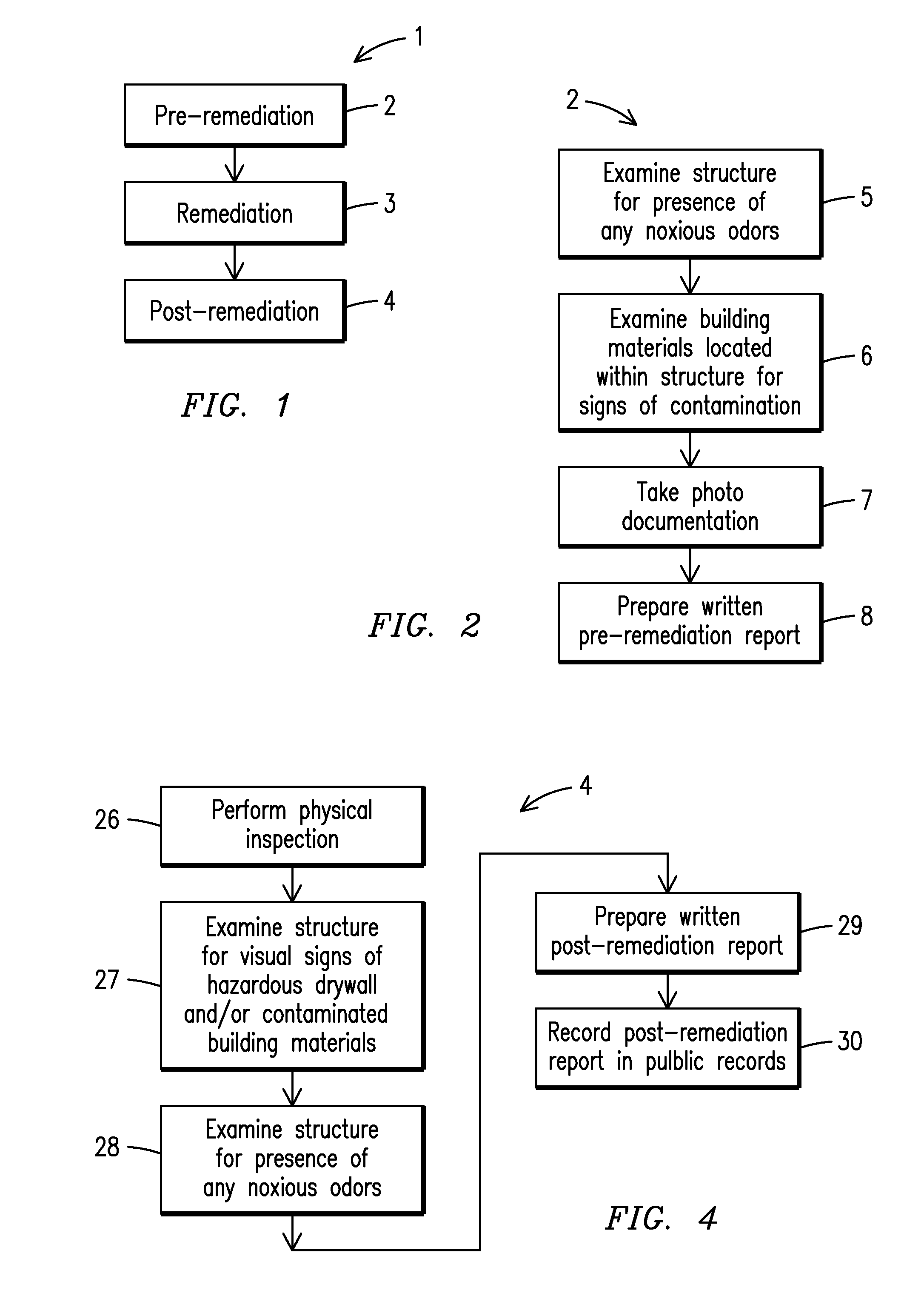

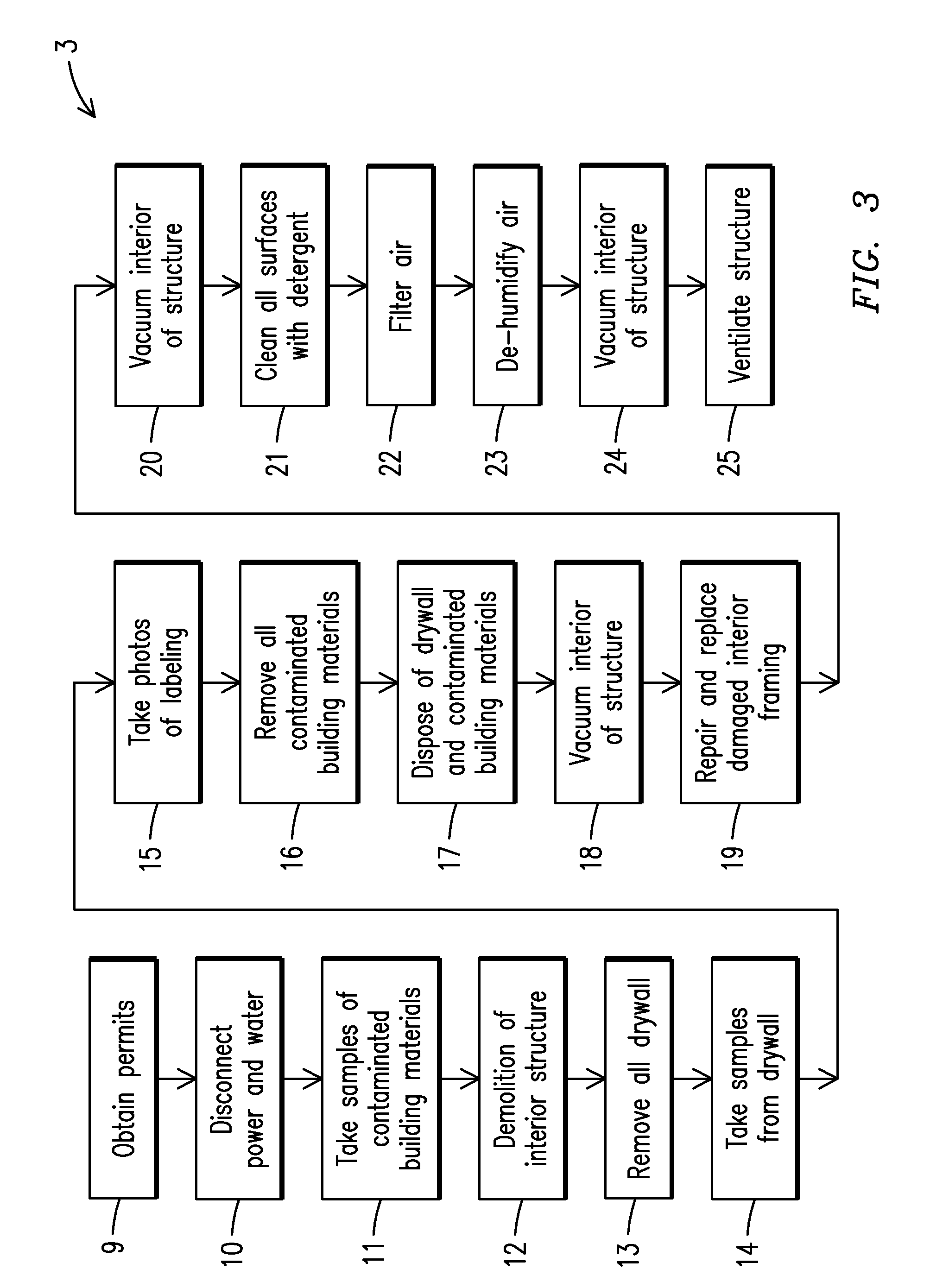

[0020]For purposes of describing the preferred embodiment, the terminology used in reference to the numbered accessories in the drawings is as follows:[0021]1. hazardous drywall remediation method and system[0022]2. pre-remediation[0023]3. remediation[0024]4. post-remediation[0025]5. examine structure for presence of noxious odors[0026]6. examine structure for visual signs of contaminated building materials[0027]7. take photo documentation[0028]8. prepare written pre-remediation report[0029]9. obtain necessary permits[0030]10. disconnect power and water[0031]11. collect samples of contaminated building materials[0032]12. demolition of interior structure[0033]13. remove all drywall[0034]14. collect samples of drywall[0035]15. take photos of labeling on drywall[0036]16. remove all contaminated building materials[0037]17. dispose of drywall and contaminated building materials[0038]18. vacuum interior of structure[0039]19. repair and / or replace damaged interior framing[0040]20. vacuum i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com