Firetube heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

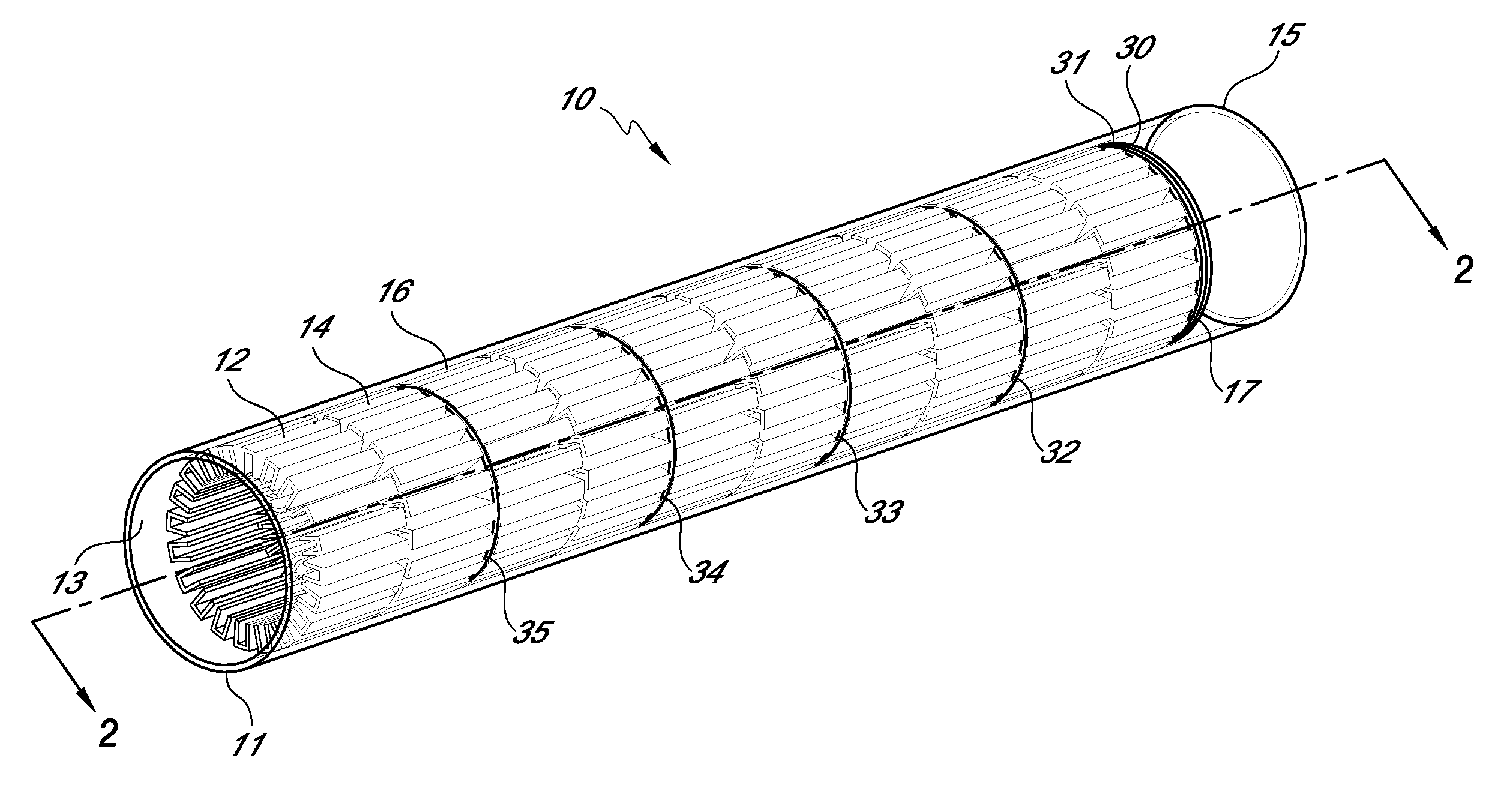

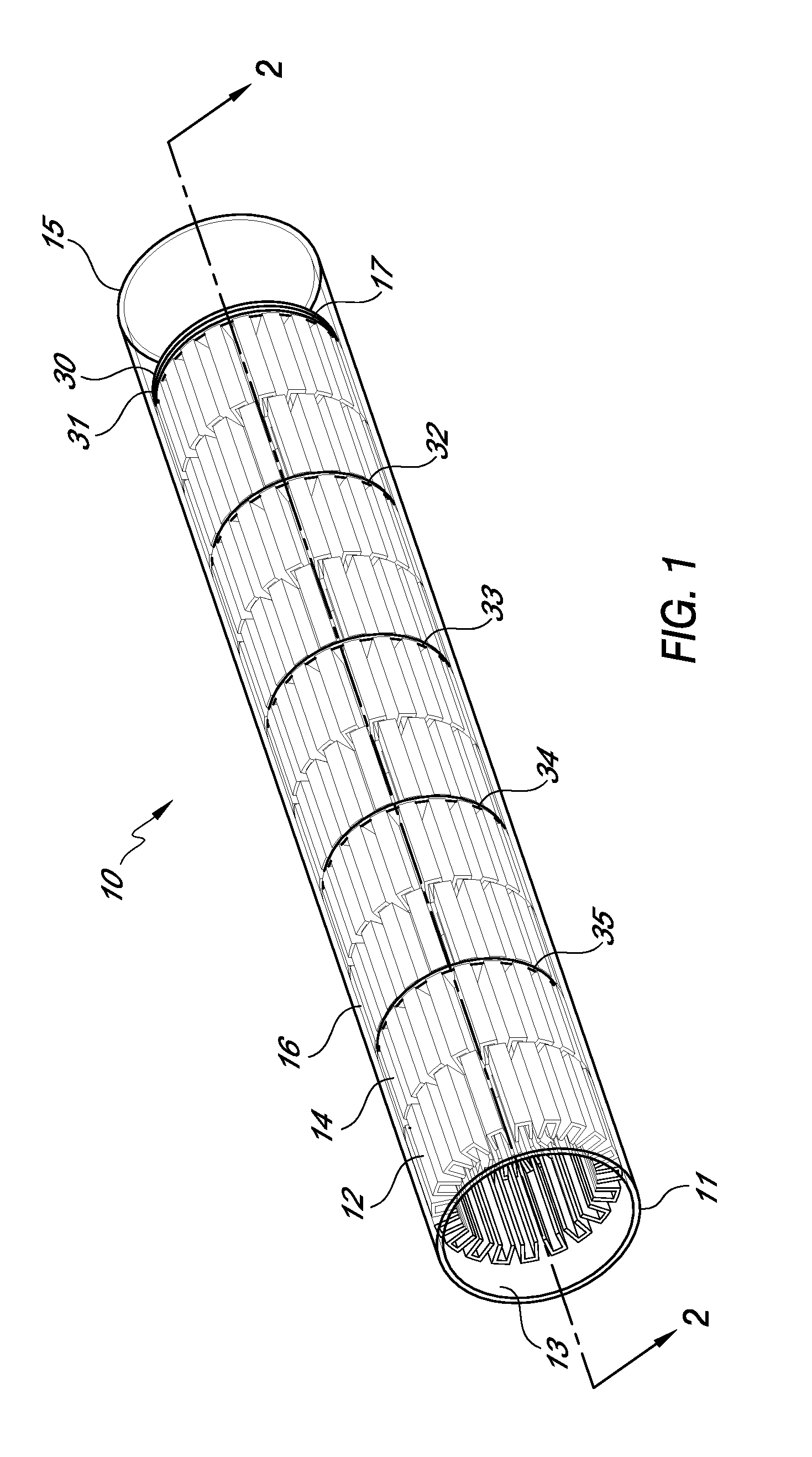

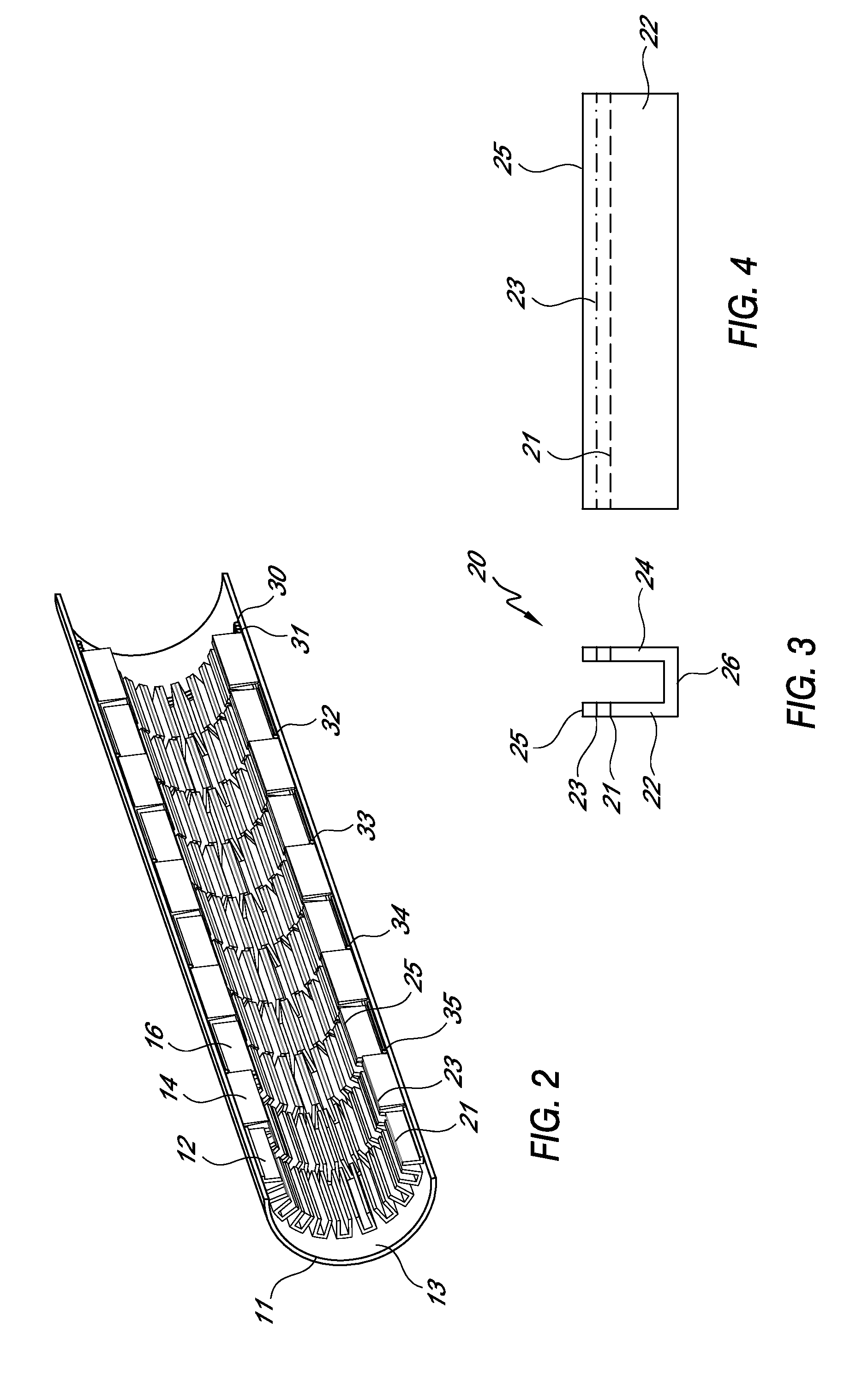

[0008]One embodiment is a firetube heat exchanger that includes an outer shell. Disposed along the interior surface of the shell is a fin assembly having a plurality of circular rows of elongated U-shaped fins. In one embodiment, each fin has a bottom surface that is secured to an inner surface of said cylindrical shell. Each fin may also have two sides extending upwardly from said bottom surface and defining an elongated interior channel. The sides may be planar and flat. In addition, in one embodiment, the fins in each row may be aligned substantially parallel along the axis of the cylindrical shell. In one embodiment, the sides of the fins in different rows have differing heights.

[0009]In FIG. 1 a firetube heat exchange assembly 10 is illustrated with the cylindrical shell 11 shown in semi-transparency for viewing the interior fins. Reference is also made to the cross-sectional view of FIG. 2 in which the cylindrical shell has been sectioned to show more particular features of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap