Printing method for reducing stitch error between overlapping jetting modules

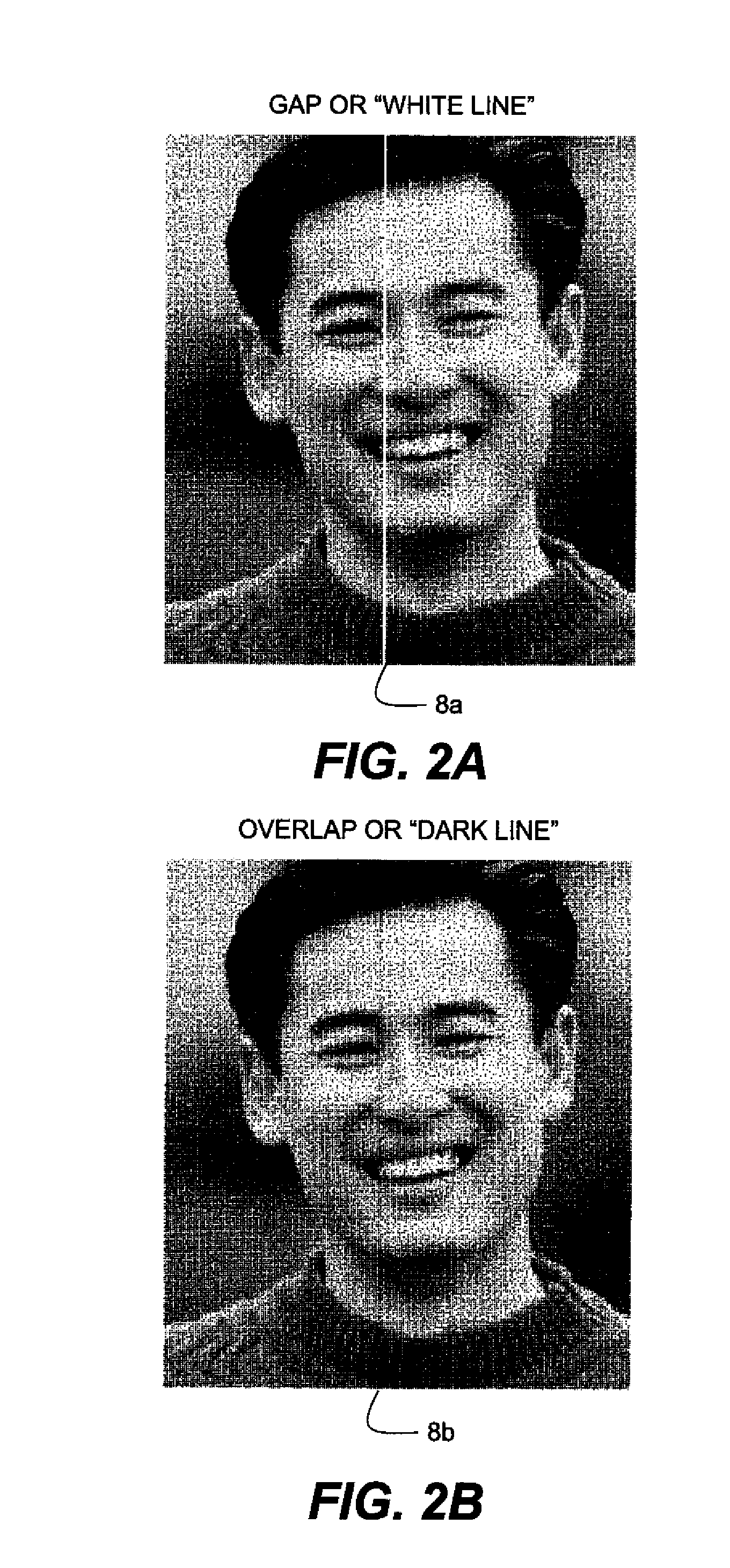

a printing method and stitching technology, applied in the field of page-width printing systems, can solve the problems that the correction amount obtained during the set-up procedure may not be suitable for all image content in the page-width printer, and the correction amount obtained during the set-up procedure may not be suitable for all density levels in the image, so as to achieve uniform correction throughout the tone scale of the image being printed, the effect of improving the distribution of data in the highlights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Because printing systems employing stitching methods are well known, the present description will be directed in particular to elements forming part of, or cooperating more directly with, methods in accordance with the present invention. Elements useful in practicing the methods but not specifically shown or described herein may be selected from those known in the art. Certain aspects of the embodiments to be described may be provided in software. Given an understanding of the system as shown and described according to the invention in the following materials, software not specifically shown, described or suggested herein that is useful for implementation of the invention is conventional and within the ordinary skill in such arts.

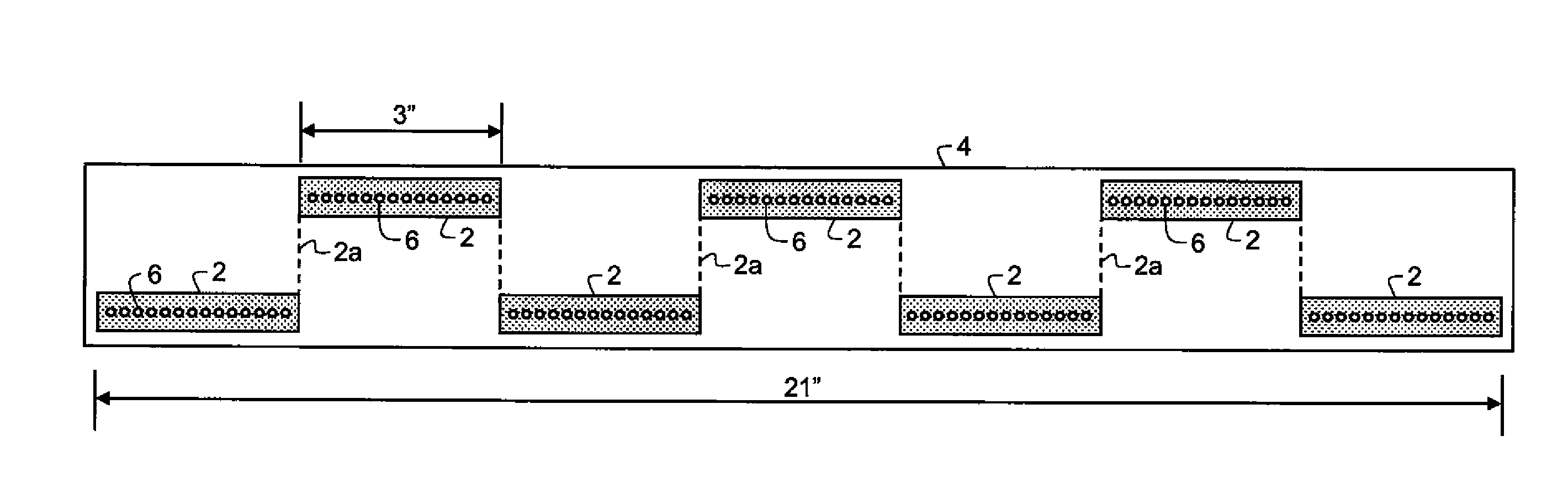

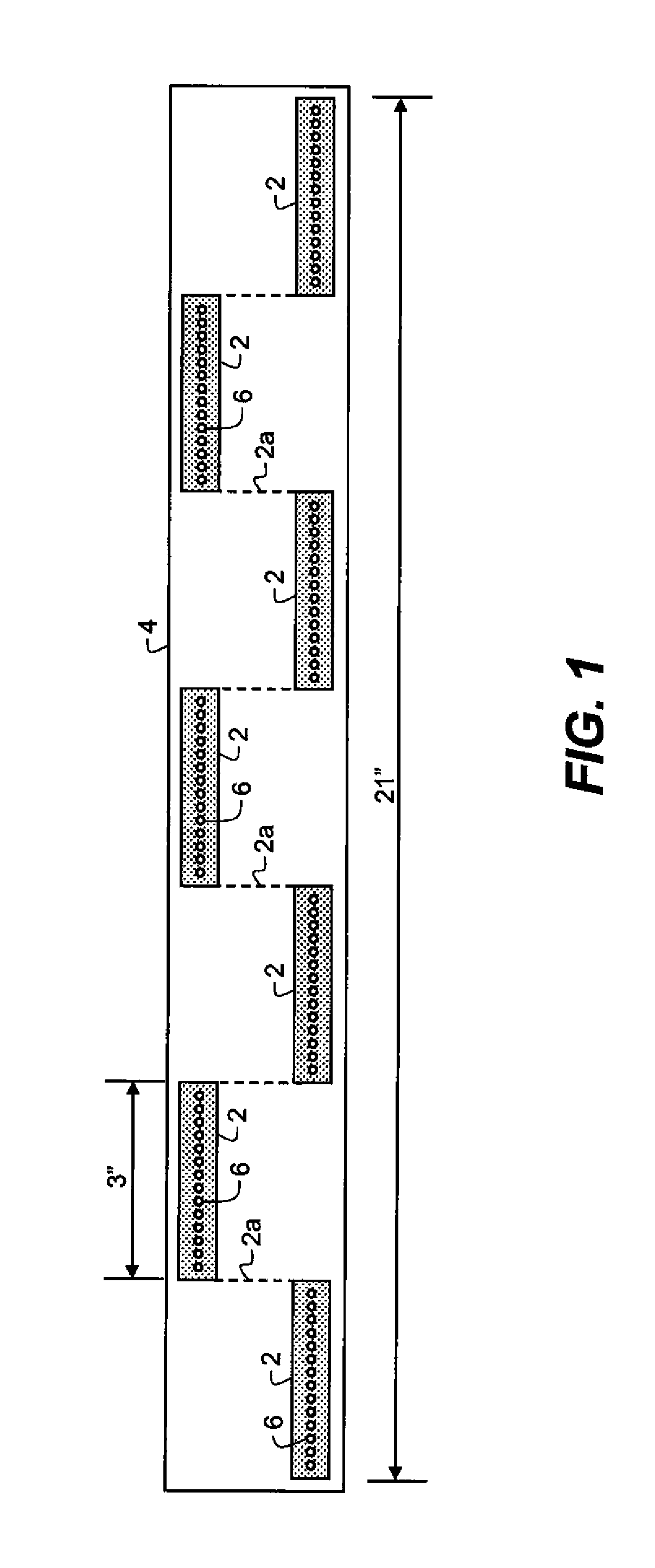

FIG. 3 shows an embodiment of a printer 10 incorporating the invention. In the embodiment of FIG. 3, the printer 10 comprises a housing 12 having a line head 14 that applies markings or otherwise forms an image on a receiver medium 16. The line head 14 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com