Bristle configuration

a tufting and toothbrush technology, applied in the field of toothbrush bristle profiles, can solve the problems of not being as adept at cleaning interdental surfaces and providing interdental stimulation as toothbrushes with contoured bristle profiles, and not all individuals floss on a regular basis, so as to achieve superior interdental cleaning, improve cleaning power, and improve cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

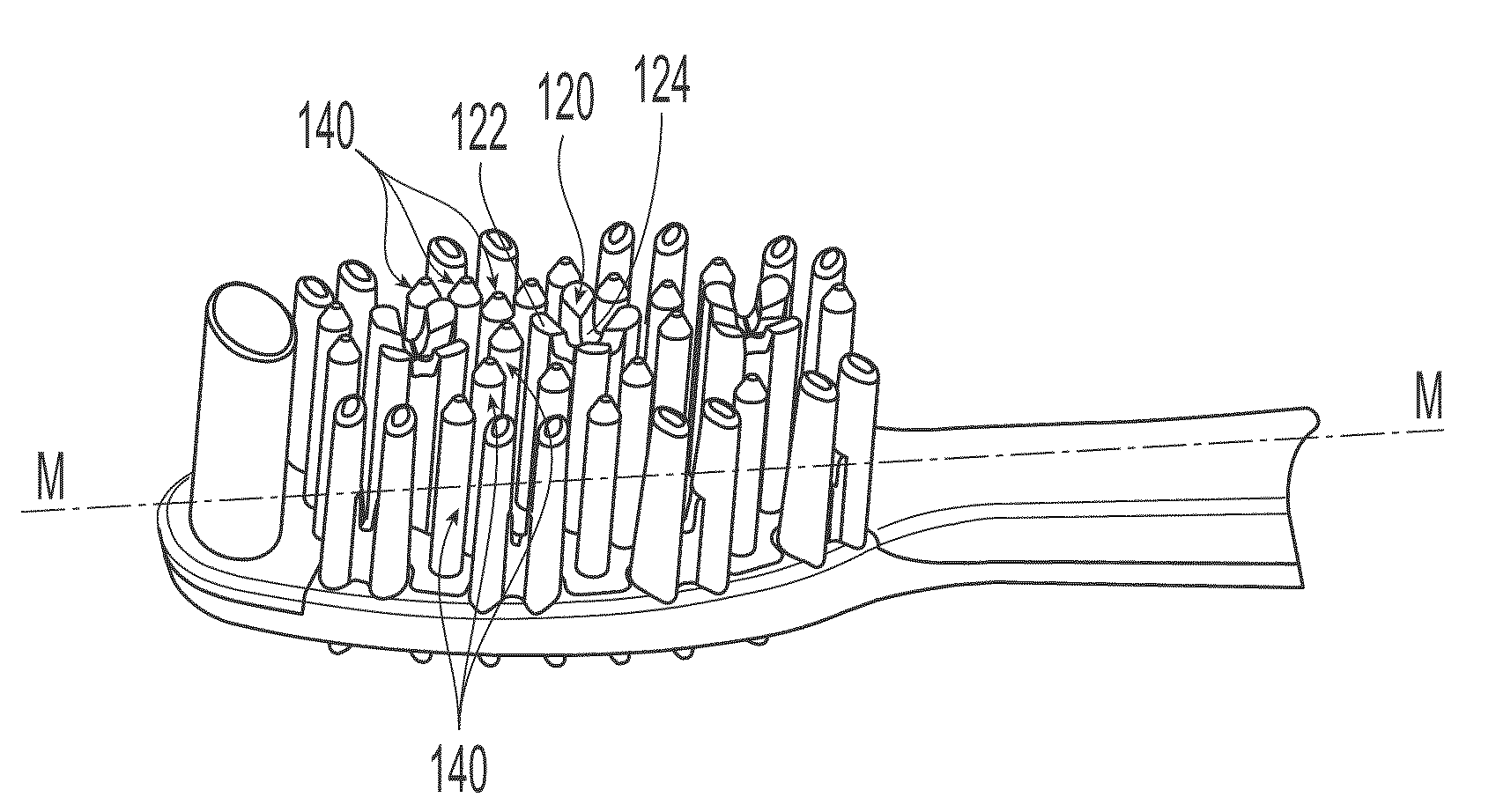

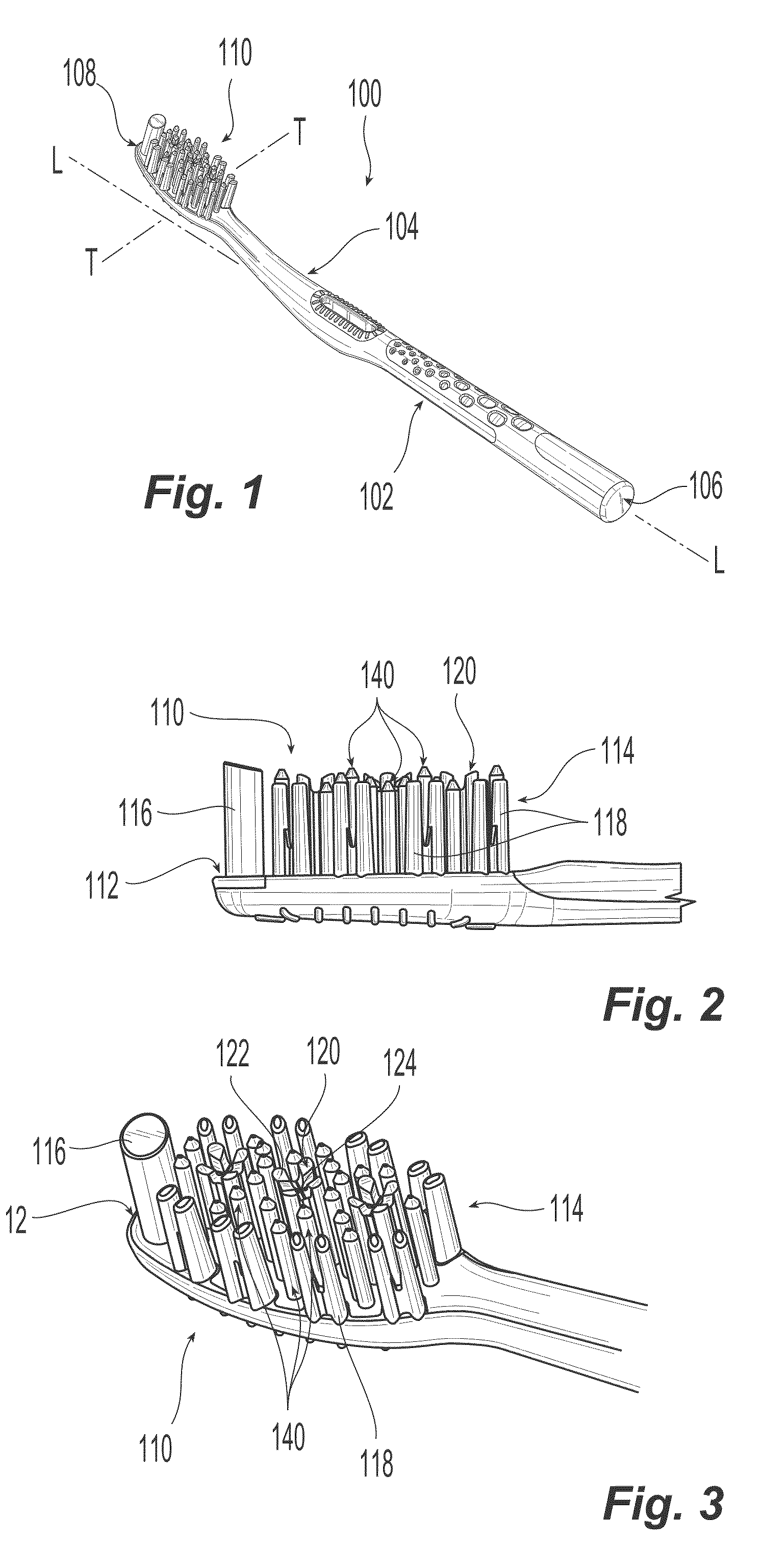

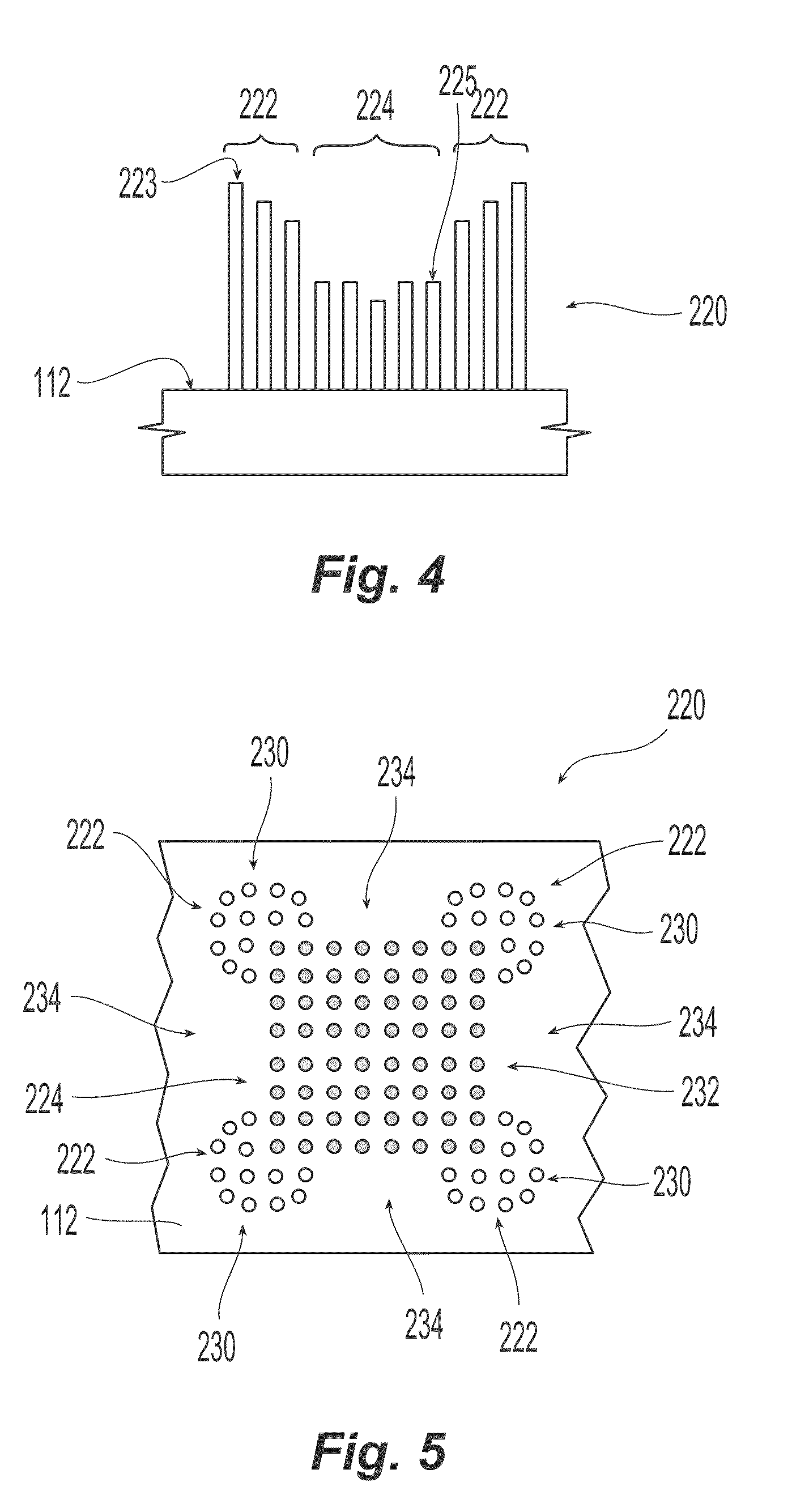

[0048]Three toothbrushes were constructed. The first toothbrush was constructed with three cross-shaped tufts as laid out in FIG. 3 with all bristles at substantially the same height (9.2 mm). A second toothbrush was constructed with three cross-shaped tufts in the same configuration and bristle density as the first brush, but with raised bristle sections and lowered bristle sections having a height difference of 1.2 mm (9.2 mm, 8.0 mm). A third toothbrush was constructed with tufts as laid out in FIGS. 1-3, but without gum massagers. The toe tuft, and frustoconical-shaped bristles, and cross-shaped tufts yielded an overall, repeating inverted “V” pattern. A fourth toothbrush was constructed with frustoconical tufts and a toe tuft as laid out in FIGS. 1-3 and 15, but without gum massagers or the large cross-shaped tufts.

[0049]Simulated plaque was applied to a human jaw model in the area between the teeth. Three hundred grams of force was applied to each head to push the bristles aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com