Big drawer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

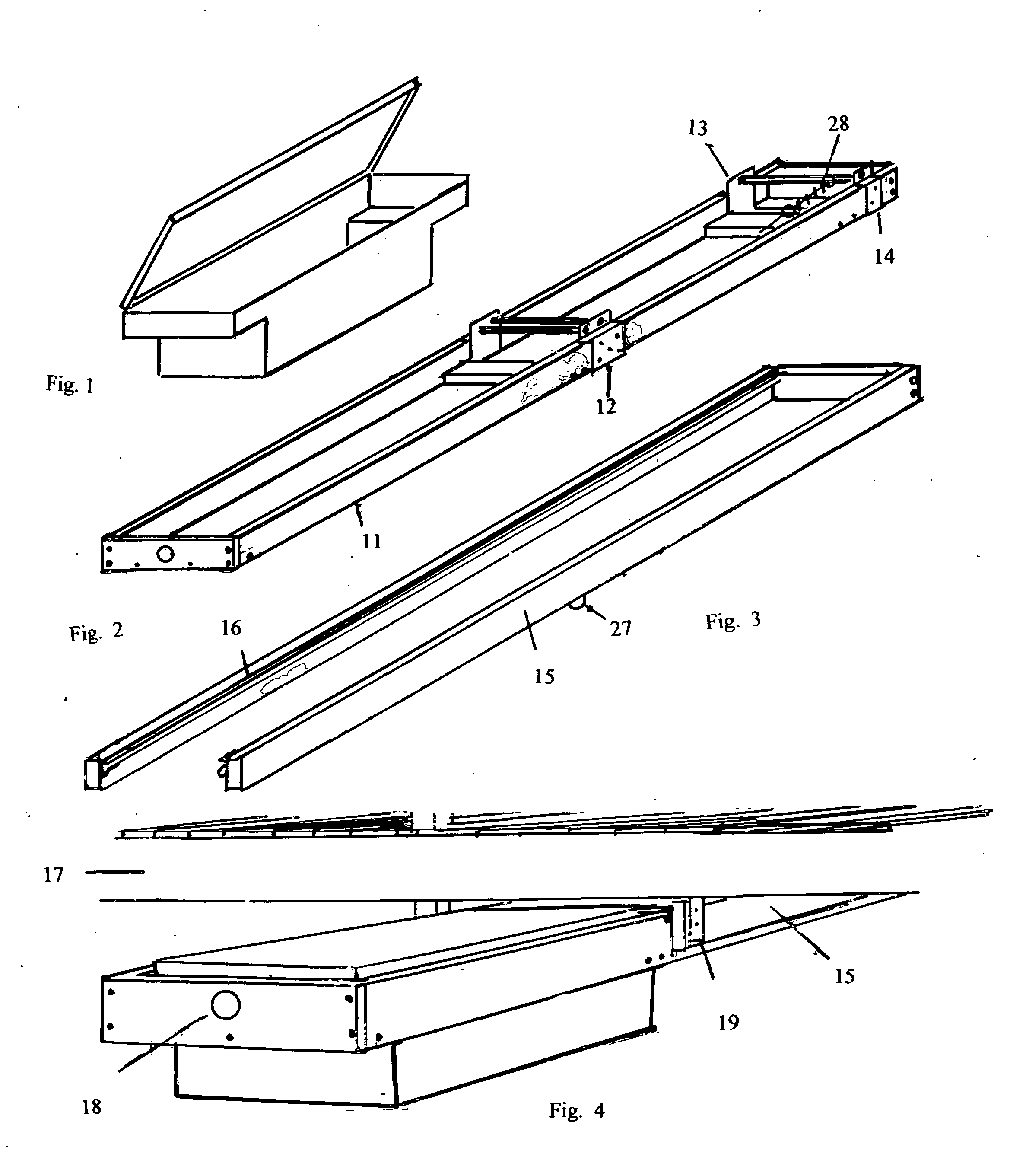

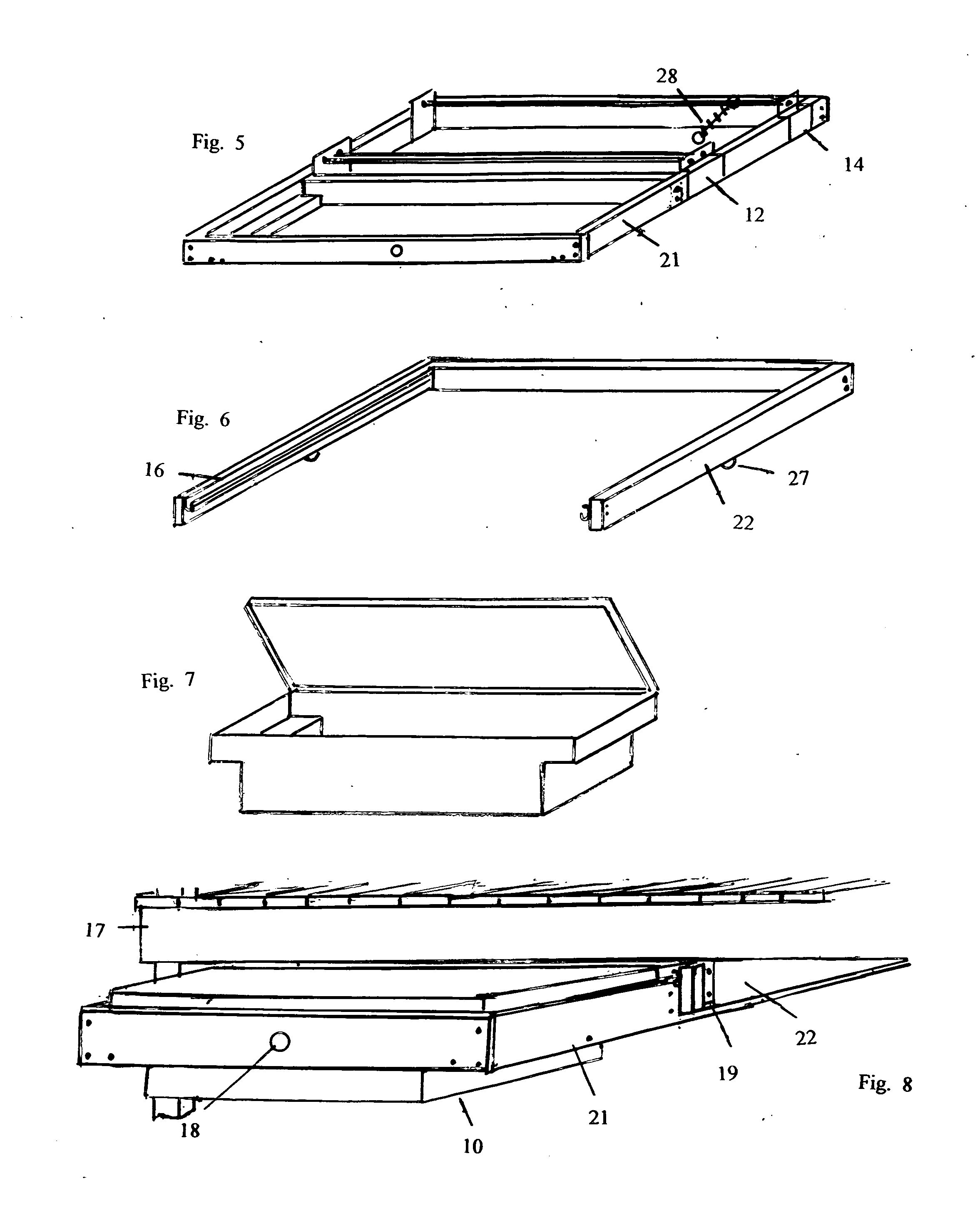

[0036]10 Full size truck crossover toolbox.

[0037]11 Side rail of trolley such as 2×6 Inch treated fir.

[0038]12 Bracket with two axle openings.

[0039]13 Axle housing such as ⅜ Inch ID galvanized pipe.

[0040]14 Bracket with one axle opening.

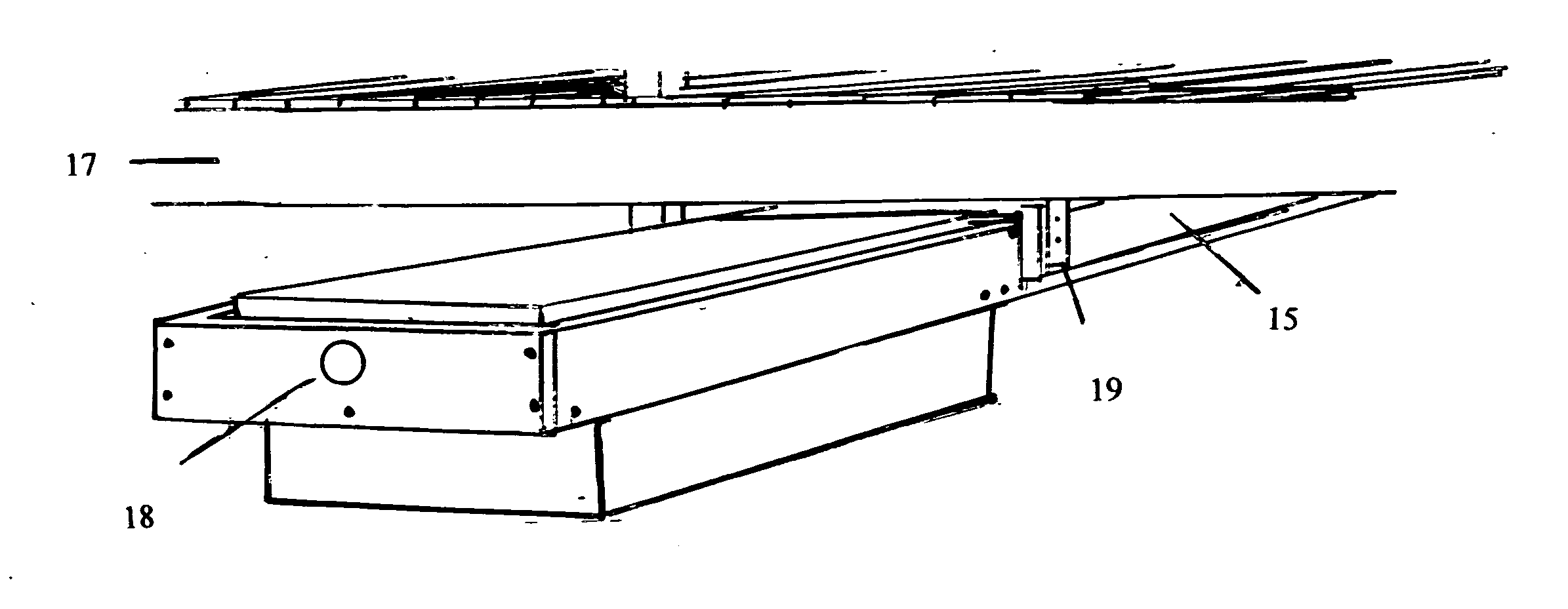

[0041]15 Side rail of carrier such as 2×6 Inch treated fir.

[0042]16 Galvanized J channel for 2 Inch rollers.

[0043]17 Typical wooden deck.

[0044]18 Access hole for unlocking toolbox.

[0045]19 Heavy Galvanized L brackets such as 1 ½×1 ½×10 Inch for attaching carrier to deck.

[0046]20 Access hole for unlocking toolbox.

[0047]21 Trolley side rail such as 2×6 Inch treated fir.

[0048]22 Carrier side rail.

[0049]23 Axle housing holes of 11 / 16 Inch.

[0050]24 Hole for 10×1 ½ Inch galvanized pan head metal screws.

[0051]25 Weatherproof 2 Inch rollers with ⅜ Inch axles.

[0052]26 Axle housings such as ⅜ Inch ID galvanized pipe.

[0053]27 Attachment point for ⅛ Inch cable.

[0054]28 Spring attached to axle housing and ⅛ Inch cable.

[0055]29 Twelve Inch piece of J track in an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com