Coverlet and Method of Producing a Coverlet

a coverlet and coverlet technology, applied in the field of unique type of coverlet and production method, can solve the problems of degrading long-term performance and not providing binding, and achieve the effect of balancing structural integrity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

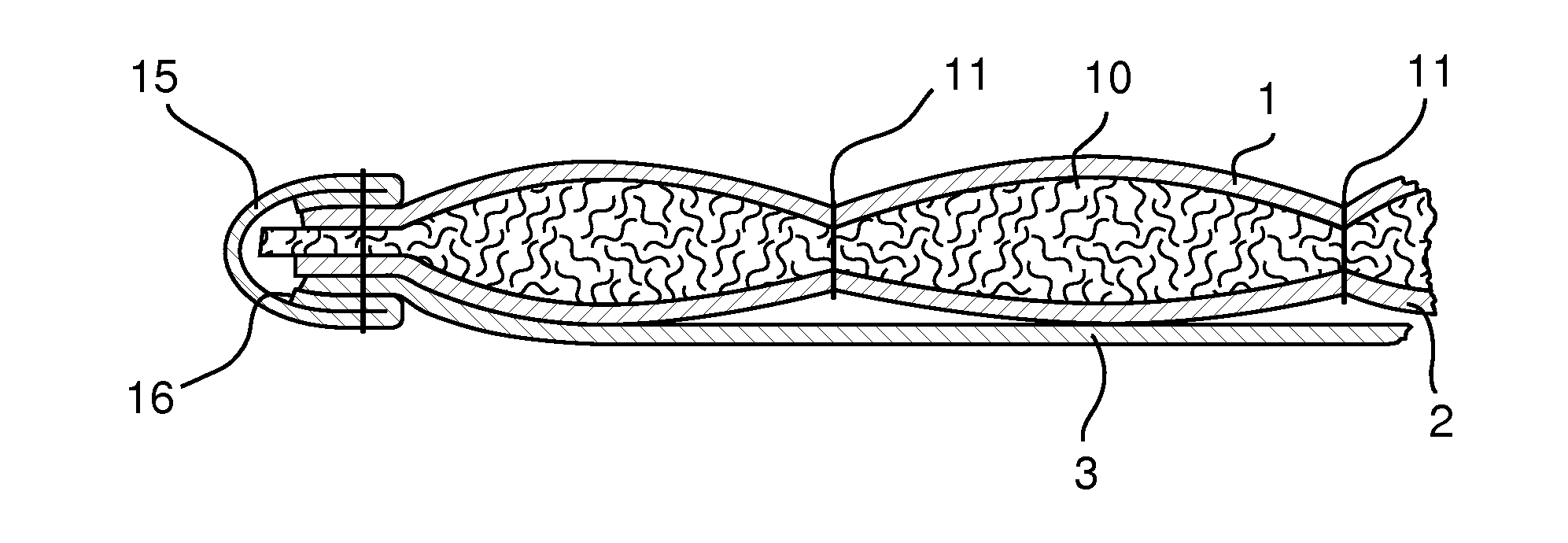

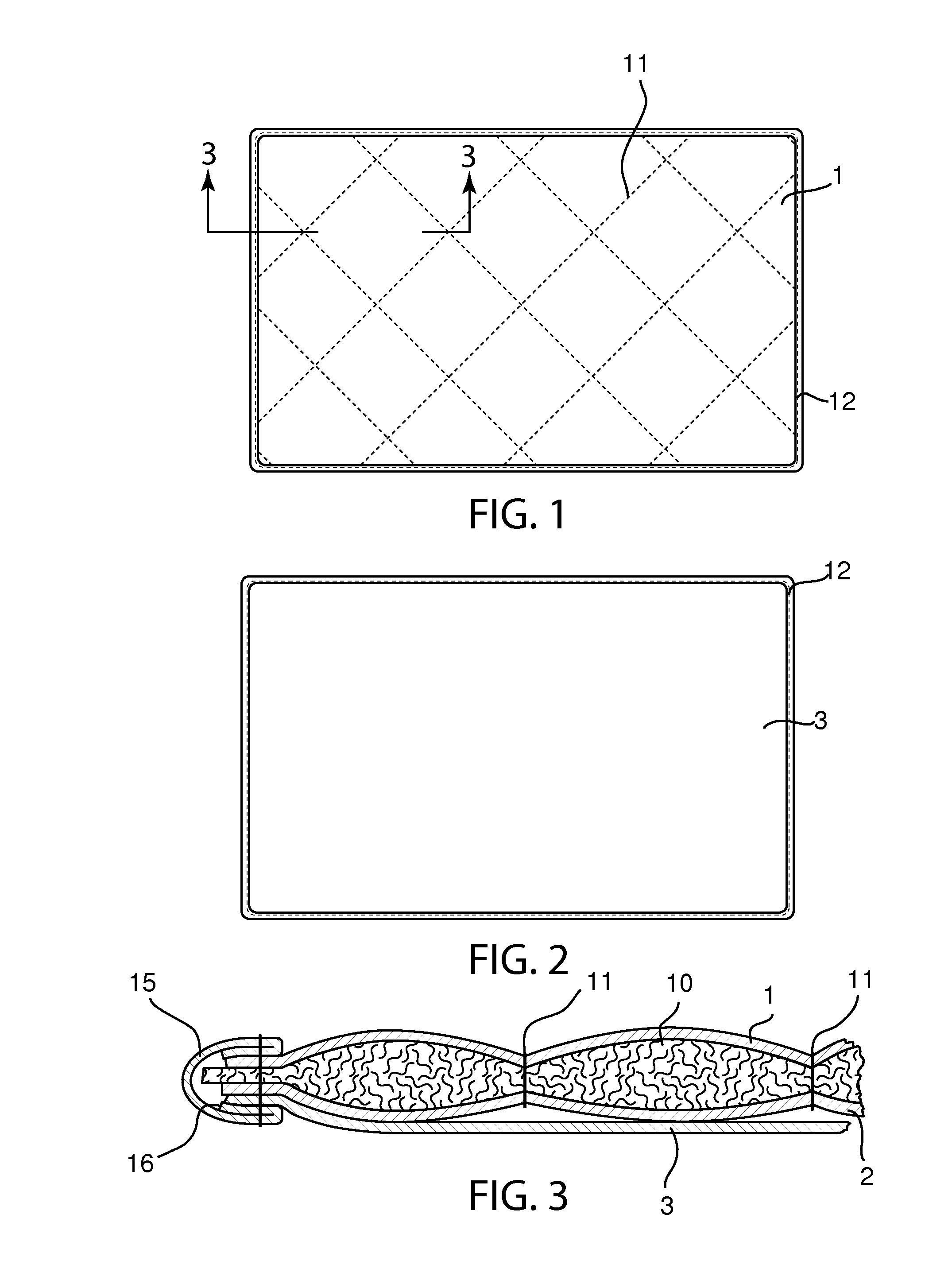

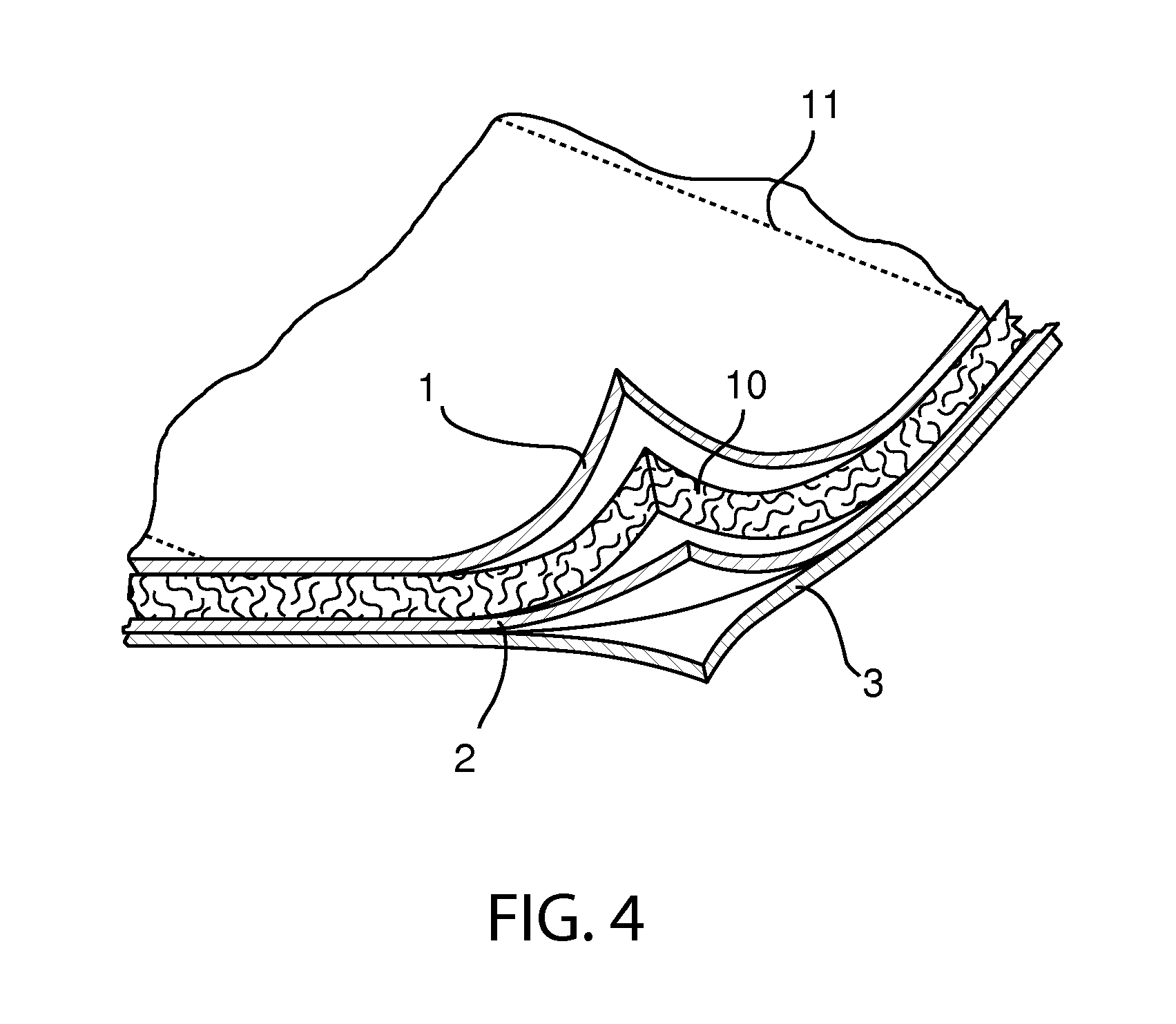

[0035]Referring now to the figures of the drawing in detail and first, particularly, to FIGS. 1 and 2 thereof, there is seen a first layer of fabric 1 forming a bottom of the coverlet and a third layer of fabric 3 forming a top of the coverlet, according to the invention.

[0036]In order to assemble the coverlet, fabric is supplied on non-illustrated rolls that are generally between 90 and 120 inches wide and between 100 and 300 yards long. The coverlet according to the invention is made in the following order. A first layer of fabric 1 is placed on a non-illustrated quilting machine. This layer 1 is known as a “back fabric” as it will be the back of the finished coverlet according to the invention. A batting 10 shown in FIG. 3 is placed on the back fabric 1. A second layer of fabric 2 is placed on the batting 10, effectively making a sandwich of the batting 10 between the two fabrics 1, 2. This second layer 2 is referred to as a “middle fabric” as it will be the middle of the finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com