Pneumatic mattress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

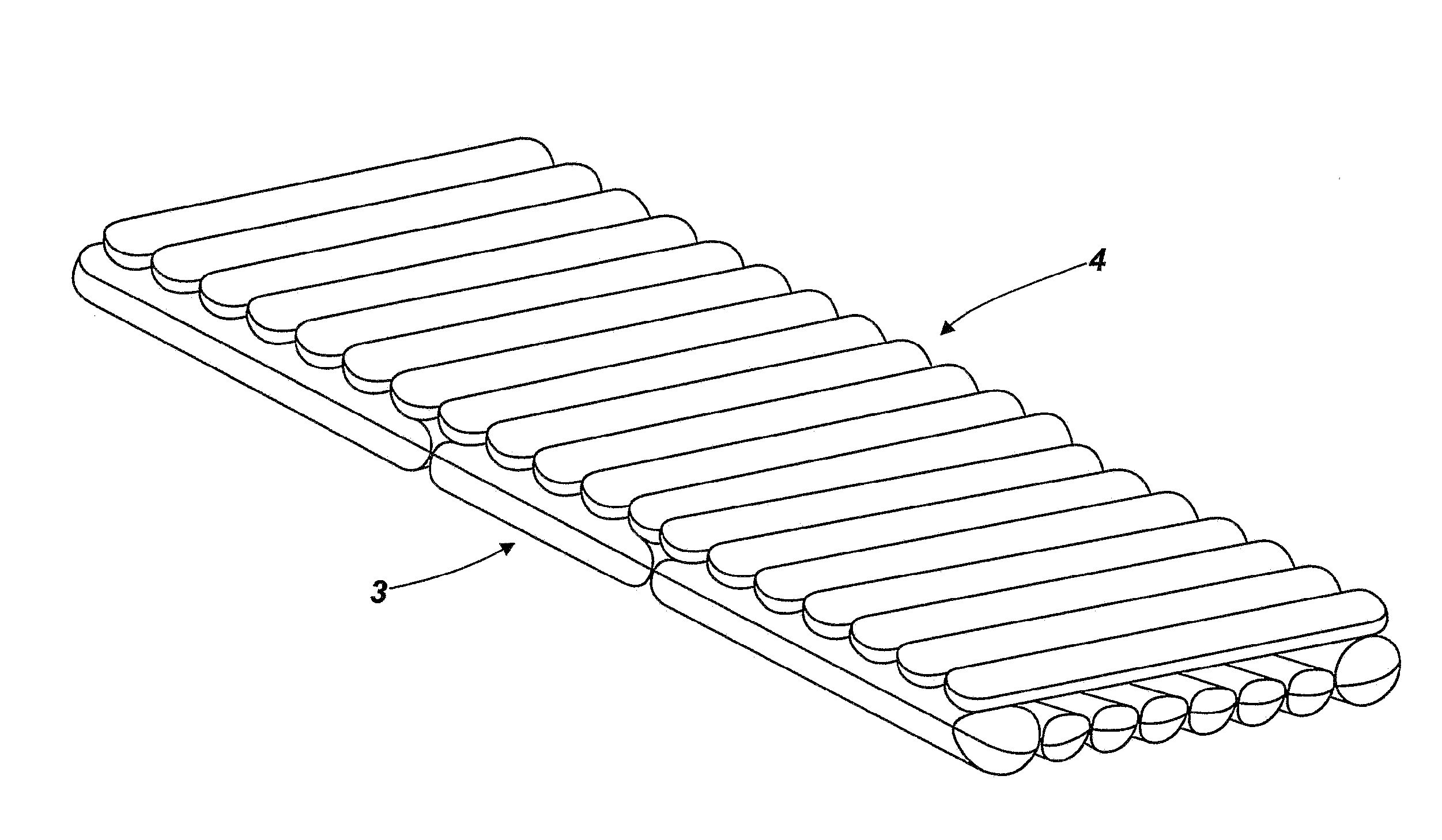

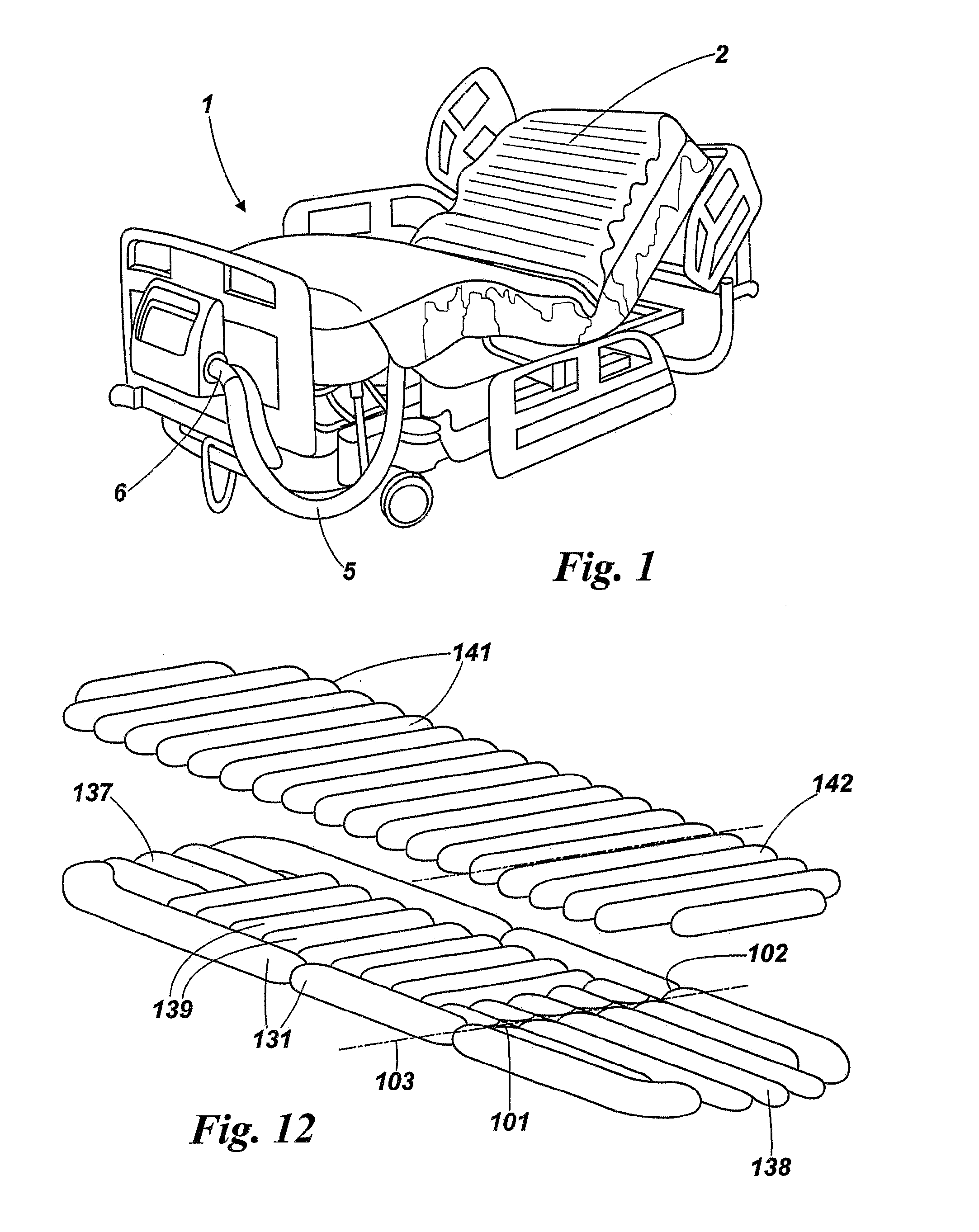

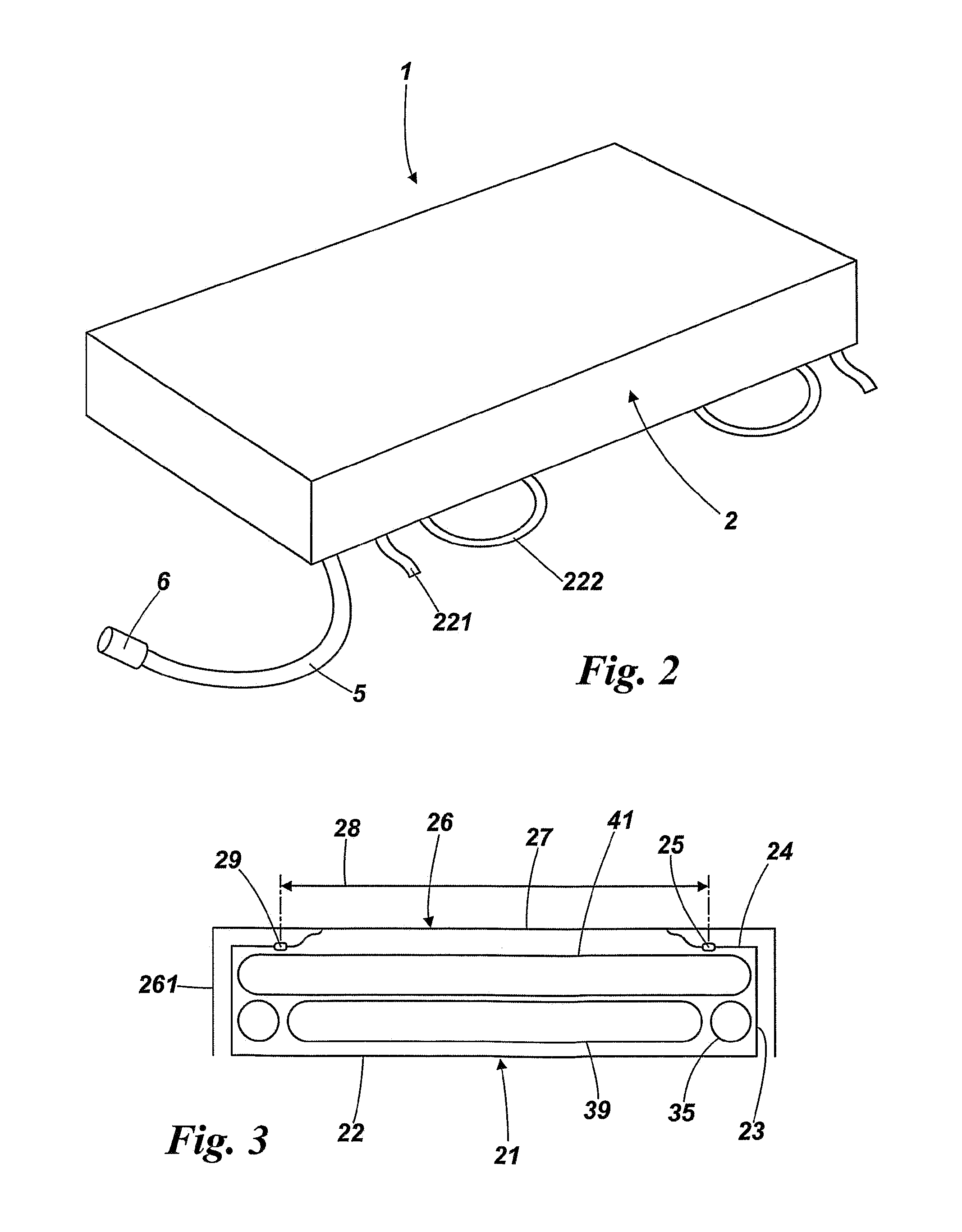

Referring to the drawings, a mattress 1 has a cover 2 enclosing two layers 3, 4 of pneumatic cells. The cells are made of impermeable sheet or tube material welded into desired shapes, typically of polyurethane material. The manner in which the cells are made is conventional, known to the skilled reader and will not be described here.

The bottom layer comprises edge cells 31 extending the full length of the mattress. These cells are closed at two positions, a hip position 32 and a knee position 33. Thus these cells have a head and back portion 34, an upper leg portion 35 and a lower leg portion 36. The portions can hinge or pivot with respect to their adjoining portions, without the pneumatic pressure in them tending to keep them rigid. Between the edge cells at the head end of the bed, i.e. between the head portions 34, six short head cells 37 are arranged with their cell length in the direction of the length of the mattress. The head cells are manufactured as a group separate from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com