Assembly, system, and method for cable tension measurement

a technology of tension measurement and cable, applied in the direction of tension measurement, force/torque/work measurement, instruments, etc., can solve problems such as damage to winch cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

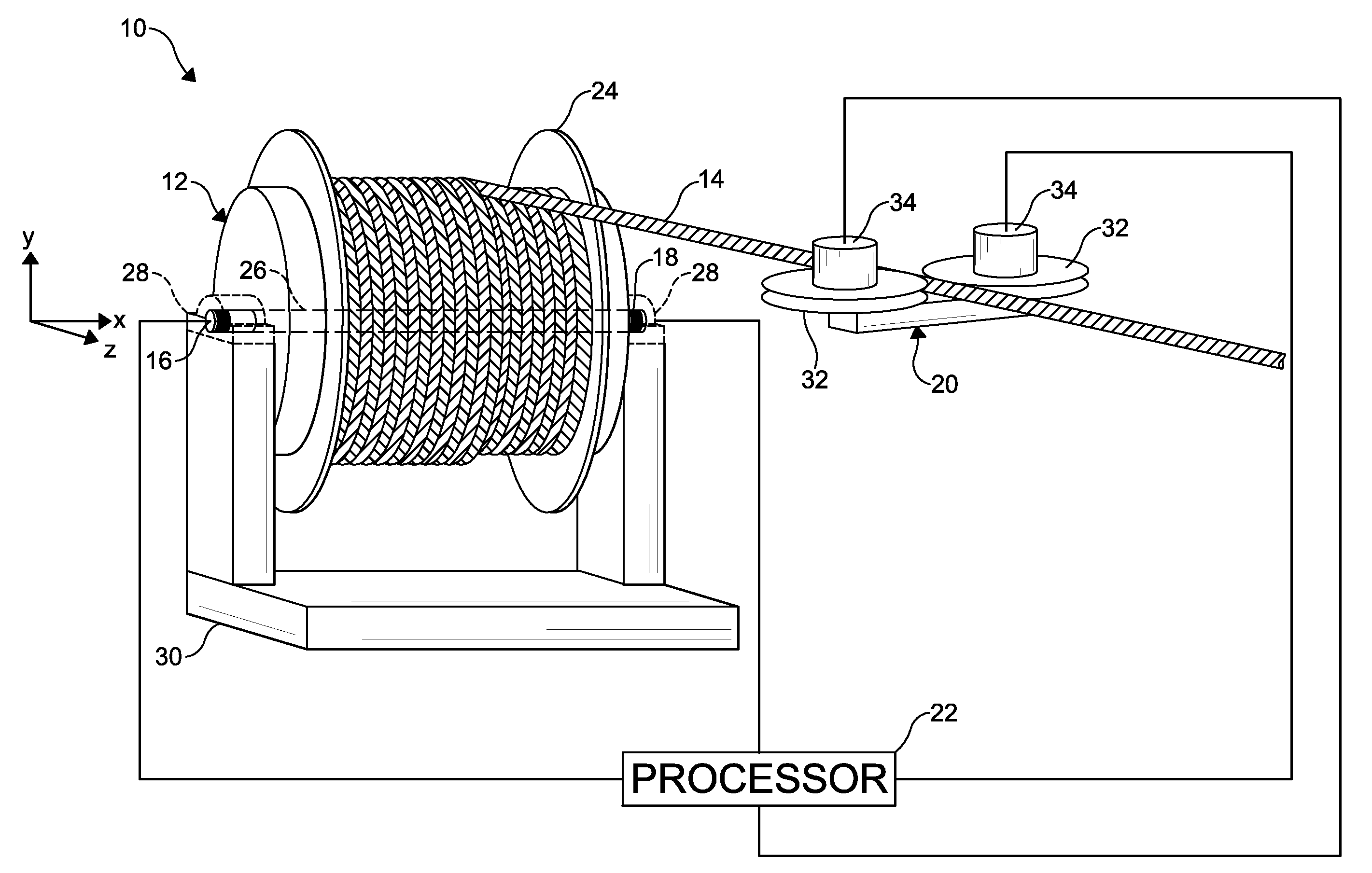

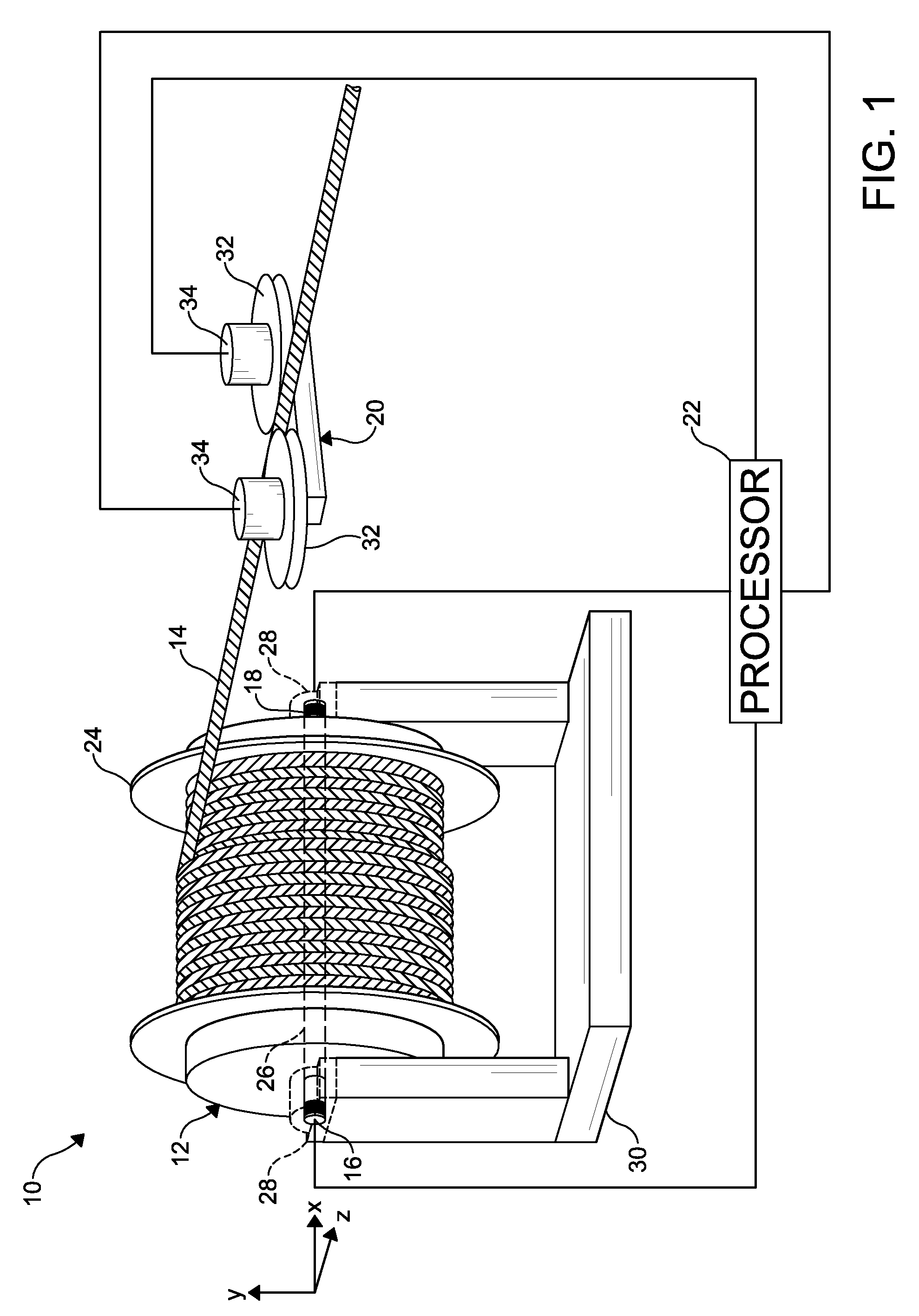

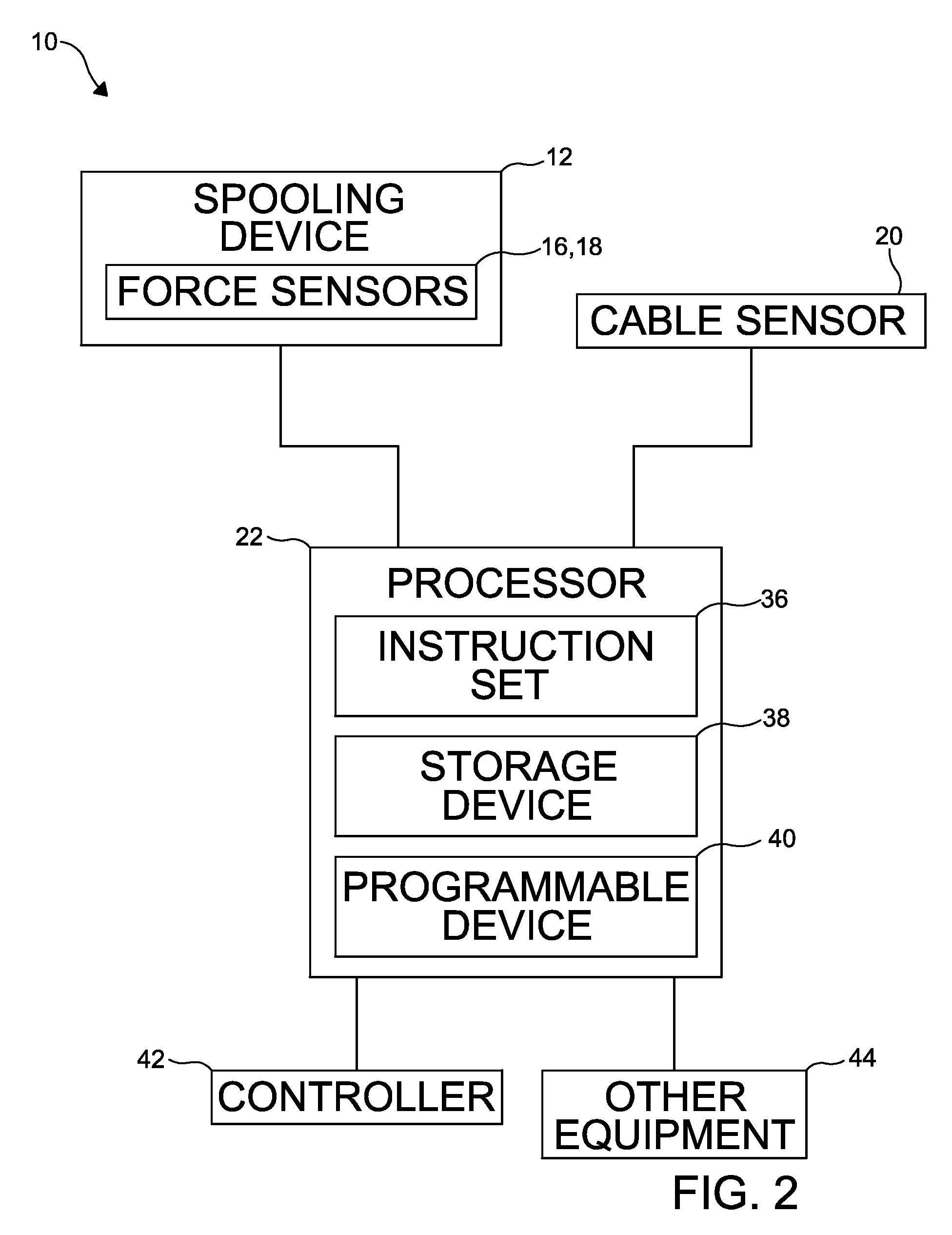

Referring now to FIGS. 1-2, there is shown an embodiment of a tension measurement system, indicated generally at 10. As shown, the tension measurement system 10 includes a spooling device 12 for spooling a cable 14, a plurality of force sensors 16, 18 positioned to measure forces acting on the spooling device 12, a cable sensor 20, and a processor 22 in communication with the force sensors 16, 18 and the cable sensor 20. Those skilled in the art will appreciate that the cable 14 may comprise a wireline electrical or electro-optical cable, a slickline cable, a length of coiled tubing, or a similar suitable spoolable device that is operable to be spooled onto the spooling device 12.

As shown in FIG. 1, the spooling device 12 includes a drum 24 having a shaft 26 (i.e. support member) disposed therethrough, wherein a portion of the shaft 26 extends from opposites sides of the drum 24. A pair of bearings 28 are disposed on a chassis 30 (e.g. cradle) and positioned to receive the portion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension measurement | aaaaa | aaaaa |

| tension force | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com