Exhaust throttle valve system and method for diesel particulate filter regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

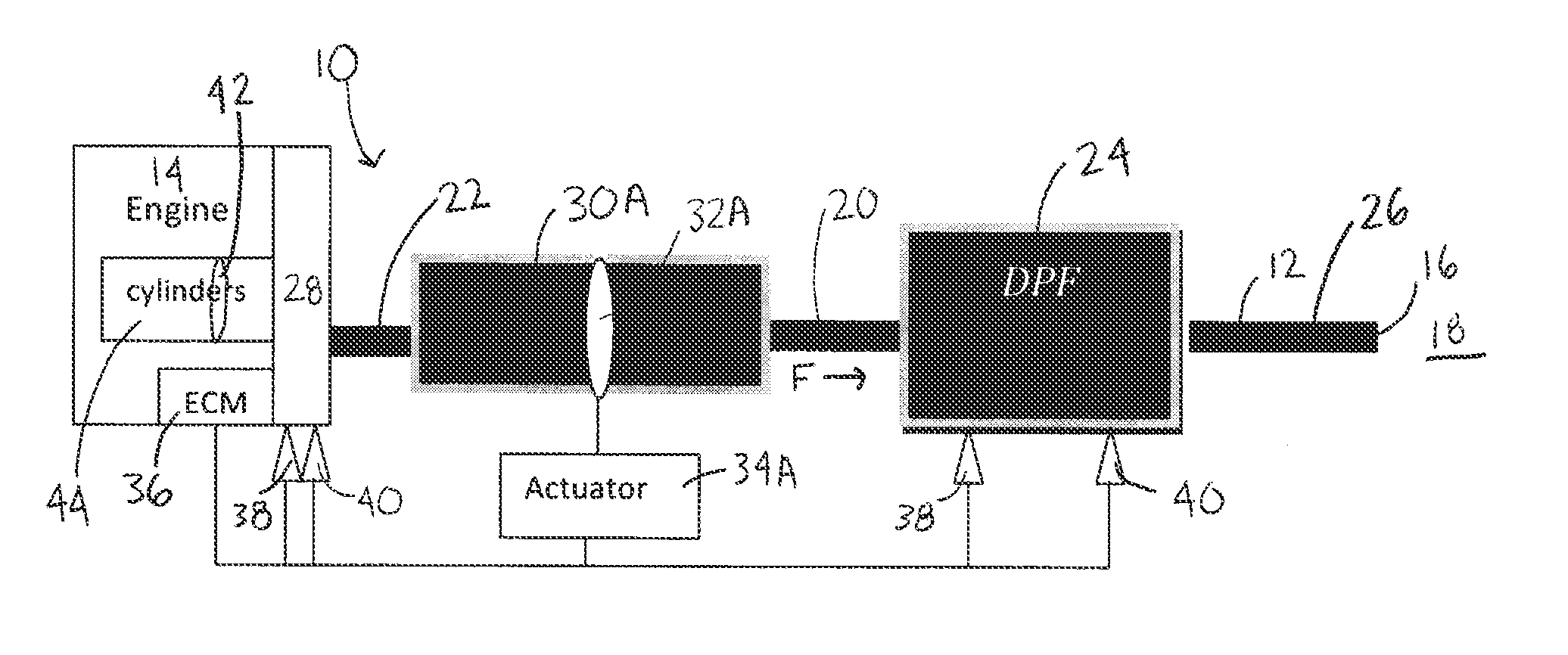

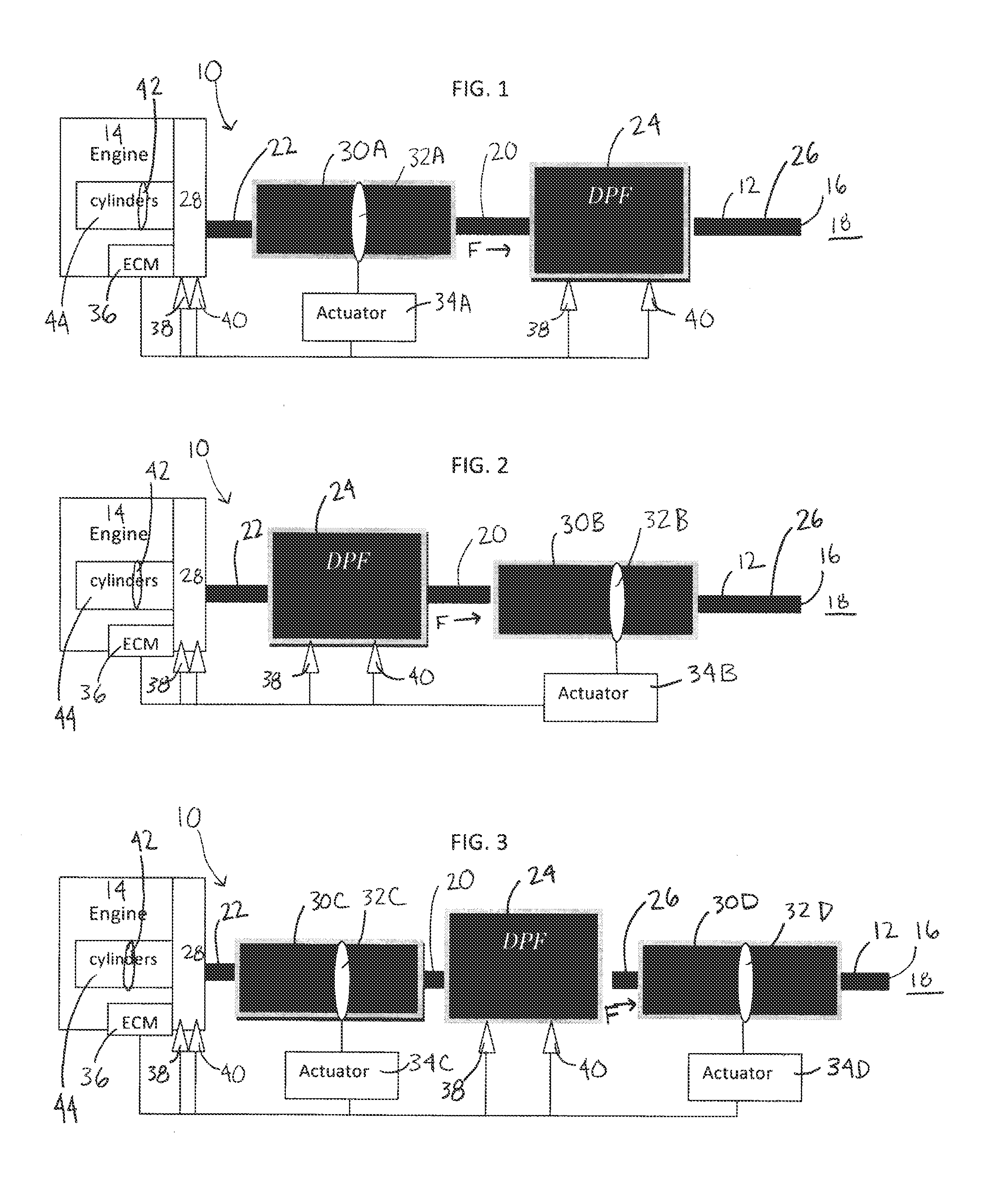

Referring to FIGS. 1-3, an exhaust gas aftertreatment system for a vehicle is indicated generally at 10, and has an exhaust pipe assembly 12 extending from an engine 14 to an outlet 16, such as the outlet to an ambient 18. The exhaust pipe assembly 12 forms a fluid passageway 20 for the flow of exhaust gas F from the engine 14 to the ambient 18. The downstream direction of exhaust gas flow F is from engine 14 to outlet 16.

A first portion 22 of the exhaust pipe assembly 12 extends from the engine 14 to a diesel particulate filter (DPF) 24. The DPF 24 is a filter constructed from a very high temperature resistant material. The DPF 24 catches and holds particulate matter entrained within the exhaust gases discharged into the exhaust aftertreatment system 10. The DPF 24 is periodically regenerated to limit increases in exhaust aftertreatment system 10 back pressure and to maintain engine 14 efficiency. A second portion 26 of the exhaust pipe assembly 12 extends from the DPF 24 to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com