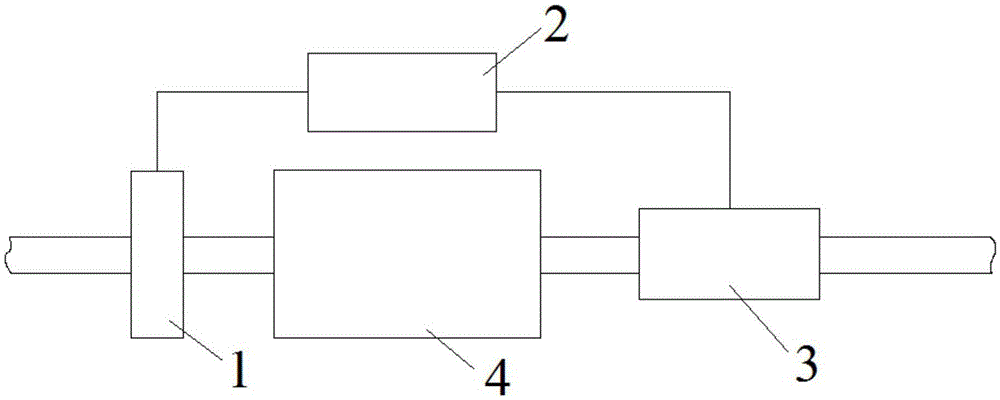

Heating device of three-way catalytic converter

A technology for catalytic converters and heating devices, applied in muffler devices, exhaust devices, machines/engines, etc., can solve the problems of increasing the cost of three-way catalytic converters, unable to exert the maximum conversion efficiency of three-way catalytic converters, etc. Good purification effect, improving conversion efficiency and increasing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0015] Because the three-way catalytic converter of the post-treatment system of general vehicles needs to reach a certain working temperature to have a certain conversion efficiency, it is called the light-off temperature (for the exhaust gas when the conversion efficiency of the exhaust pollutants of each vehicle reaches more than 50%) Temperature), generally around 300°C, and to make the conversion efficiency of the three-way catalytic converter reach more than 90%, its inlet temperature needs to reach at least 600°C, and the rear stage of ordinary gasoline vehicles no matter whether it is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com