Automatic fast rewinder for shaftless packing film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

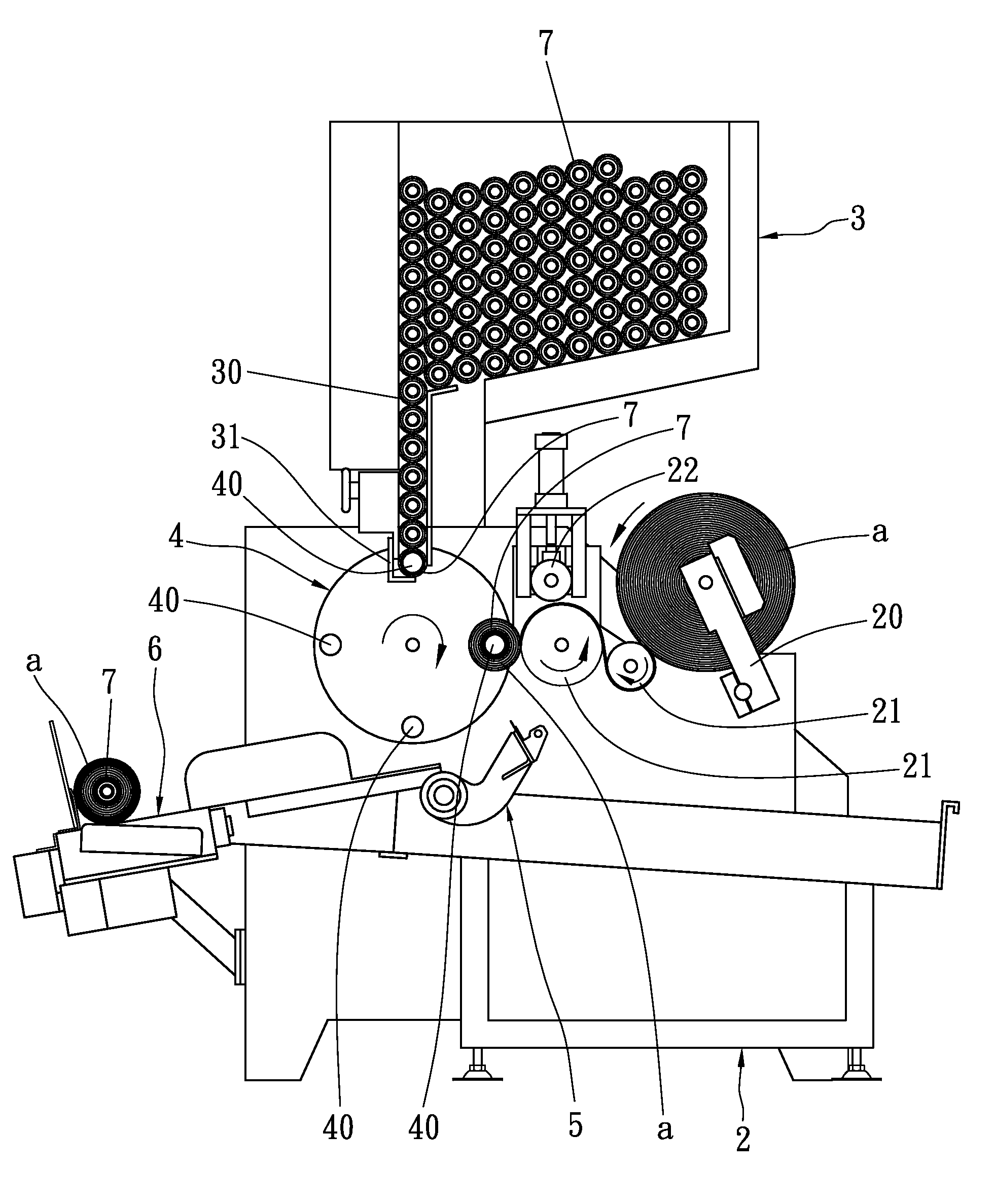

[0017]A preferred embodiment of an automatic fast rewinder for shaftless packing film in the present invention, as shown in FIGS. 4, 5 and 6, includes a body 2, a support frame 20, plural guide wheels 21, a pressing wheel 22, a feeding box 3, a pair of rotary discs 4, a saw-teeth cutting unit 5, a collect unit 7 and plural inflatable shafts 7.

[0018]The support frame 20 is positioned on the body 1 for holding a large roll of packing film (a).

[0019]The plural guide wheels 21 and the pressing wheel 22 are arranged orderly on the body 2 and rotated to move the packing film (a) from the large roll held on the support frame 20.

[0020]The feeding box 3 is placed on the body 2 for containing a number of the inflatable shafts 7 in the inflated condition, provided with a guide passage 30 extending down from one side of the bottom for the inflated shafts 7 to orderly falling down, and a stopper 31 fixed at a lower end of the guide passage 30 for stopping a lowest inflated shaft 7.

[0021]The pair...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com