Method for jointly producing polyhydroxyalkanoate by residual sludge and Baijiu wastewater

A technology of polyhydroxyalkanoate and excess sludge, applied in the fields of environmental protection and resource utilization, can solve the problems of low VFAs yield, limit the yield of PHA synthesis from activated sludge, etc., achieve high utilization value, and promote output increase. , the effect of promoting synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for joint production of polyhydroxyalkanoate by utilizing excess sludge and liquor waste water comprises the following steps:

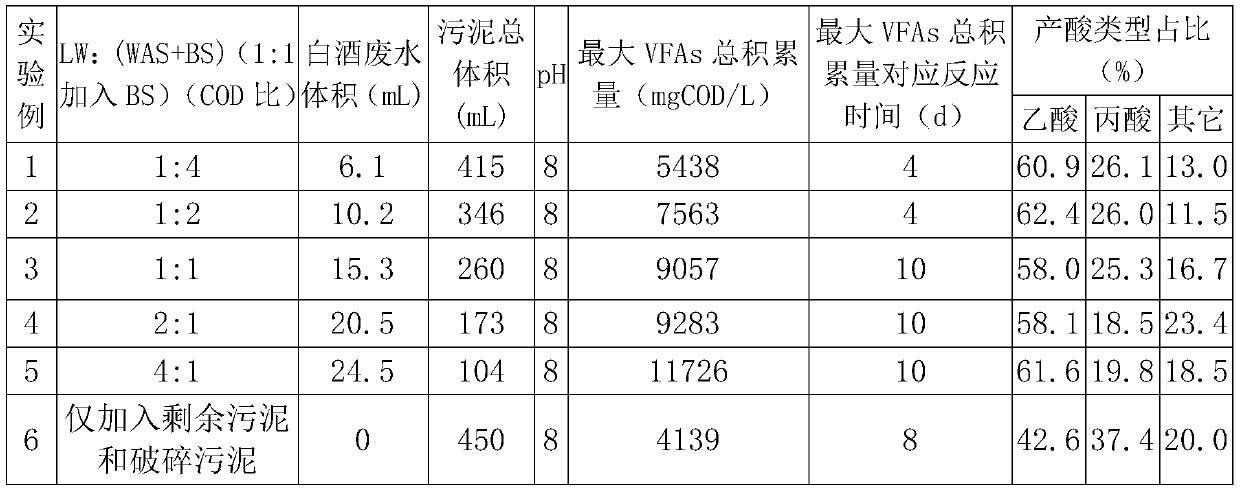

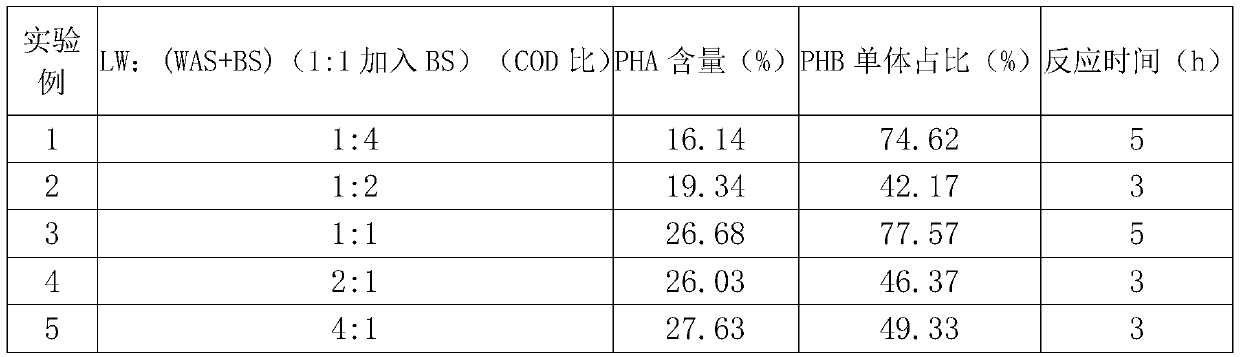

[0026] (1) Fill 6.1mL of liquor wastewater and 415mL of residual sludge added with crushed sludge into a sealed brine bottle with an effective volume of 450mL. Adjust the pH to 8. In order to ensure that the reaction is carried out under anaerobic conditions, use nitrogen to purify for about 3 minutes and then cork the bottle tightly. Finally, put the brine bottle in a constant temperature shaker with a temperature of 35 ° C and a speed of 180 rpm for the reaction. The maximum total accumulation of VFAs was 5438mgCOD / L, corresponding to a reaction time of 4 days.

[0027] (2) A sequencing batch reactor with an effective volume of 9L is used to control the SBR reaction platform with a timing controller, so that it can perform "feeding-aeration-sedimentation-drainage-feeding" according to the Feast-Famine mode cycle. The SBR was perf...

Embodiment 2

[0030] The method for joint production of polyhydroxyalkanoate by utilizing excess sludge and liquor waste water comprises the following steps:

[0031] (1) 10.2 mL of liquor wastewater and 346 mL of residual sludge added with crushed sludge were placed in a sealed brine bottle with an effective volume of 450 mL. Adjust the pH to 8. In order to ensure that the reaction is carried out under anaerobic conditions, use nitrogen to purify for about 3 minutes and then cork the bottle tightly. Finally, put the brine bottle in a constant temperature shaker with a temperature of 35 ° C and a speed of 180 rpm for the reaction. The maximum total accumulation of VFAs was 7563mgCOD / L, corresponding to a reaction time of 4 days.

[0032] (2) A sequencing batch reactor with an effective volume of 9L is used to control the SBR reaction platform with a timing controller, so that it can perform "feeding-aeration-sedimentation-drainage-feeding" according to the Feast-Famine mode cycle. The SBR...

Embodiment 3

[0035] The method for joint production of polyhydroxyalkanoate by utilizing excess sludge and liquor waste water comprises the following steps:

[0036] (1) 15.3 mL of liquor wastewater and 260 mL of residual sludge added with crushed sludge were placed in a sealed brine bottle with an effective volume of 450 mL. Adjust the pH to 8. In order to ensure that the reaction is carried out under anaerobic conditions, use nitrogen to purify for about 3 minutes and then cork the bottle tightly. Finally, put the brine bottle in a constant temperature shaker with a temperature of 35 ° C and a speed of 180 rpm for the reaction. The maximum total accumulation of VFAs was 9057mgCOD / L, corresponding to a reaction time of 10 days.

[0037] (2) A sequencing batch reactor with an effective volume of 9L is used to control the SBR reaction platform with a timing controller, so that it can perform "feeding-aeration-sedimentation-drainage-feeding" according to the Feast-Famine mode cycle. The SBR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com