Use of alpha-amino ethers for the removal of hydrogen sulfide from hydrocarbons

a technology of alpha-amino ethers and hydrocarbons, which is applied in the treatment of hydrocarbon oils, organic chemistry, chemistry apparatus and processes, etc., can solve the problems of significant mixing and achieve the effect of reducing the amount of hydrogen sulfide released

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

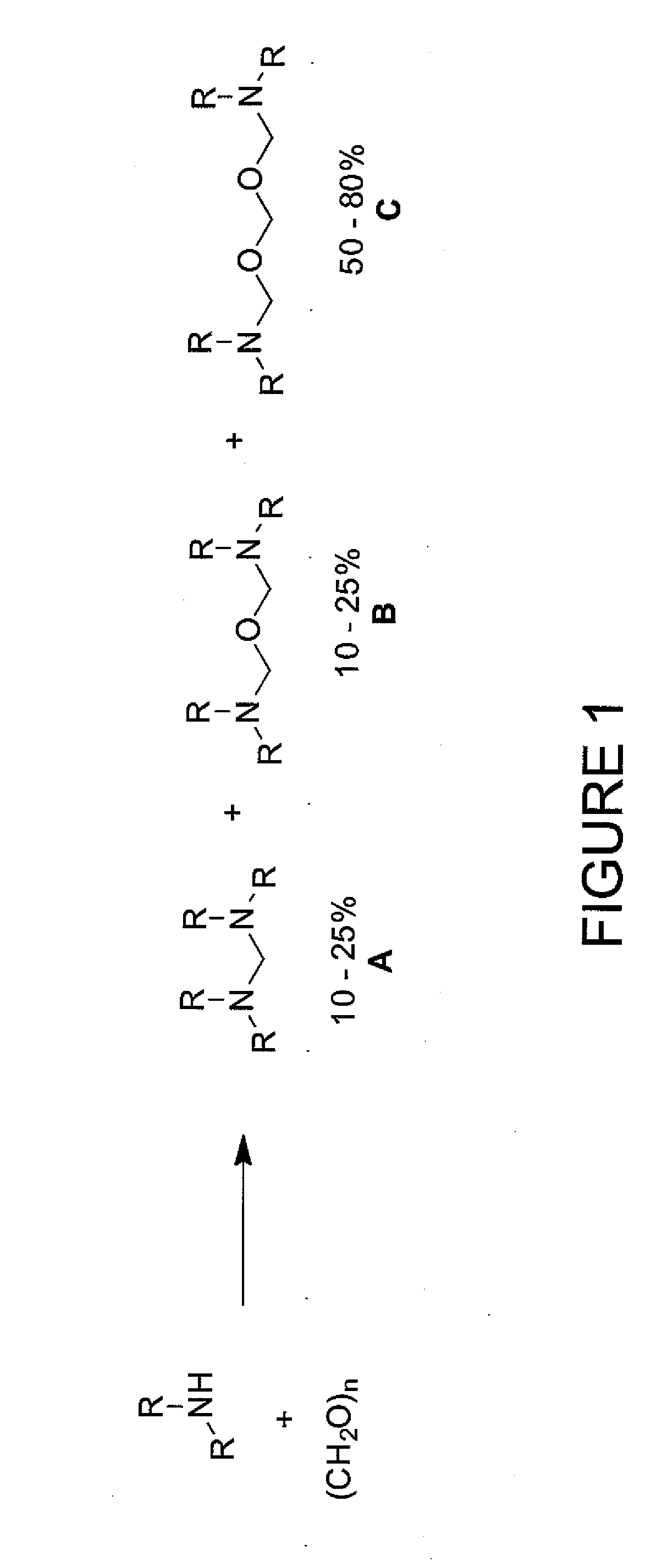

Method used

Image

Examples

examples

[0032]The foregoing may be better understood by reference to the following example, which is presented for purposes of illustration and is not intended to limit the scope of the invention.

[0033]Samples of hydrocarbon fluids were tested to determine the efficiency of the scavenger. Table 1 compares the inventive composition in naphtha at 22 degrees C., Table 2 kerosene at 22 degrees C., and Table 3 slurry oil (such as carbon black oil, decant oil, and clarified slurry oil produced in a refinery) at 97 degrees C. The samples contained variable levels of hydrogen sulfide and were comparatively treated with various dosages of alpha-amino ether scavenger or left untreated, and the amounts H2S reduced in each sample was recorded.

Table 1: Naphtha 22° C.H2Slevlesppm H2SPercentDoseTreatment(ppm)ReducedReductionRatioTimeUntreated800Compounds A-C2078097.50.22 hCompounds A-C679499.20.32 hCompounds A-C379799.60.224 hCompounds A-C>79999.90.324hCompounds A-C12 788 98.5 0.22 h(4)(796)(99.5)(24 h)Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| soluble | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap