Inertia free drive for cryogenic piston expander

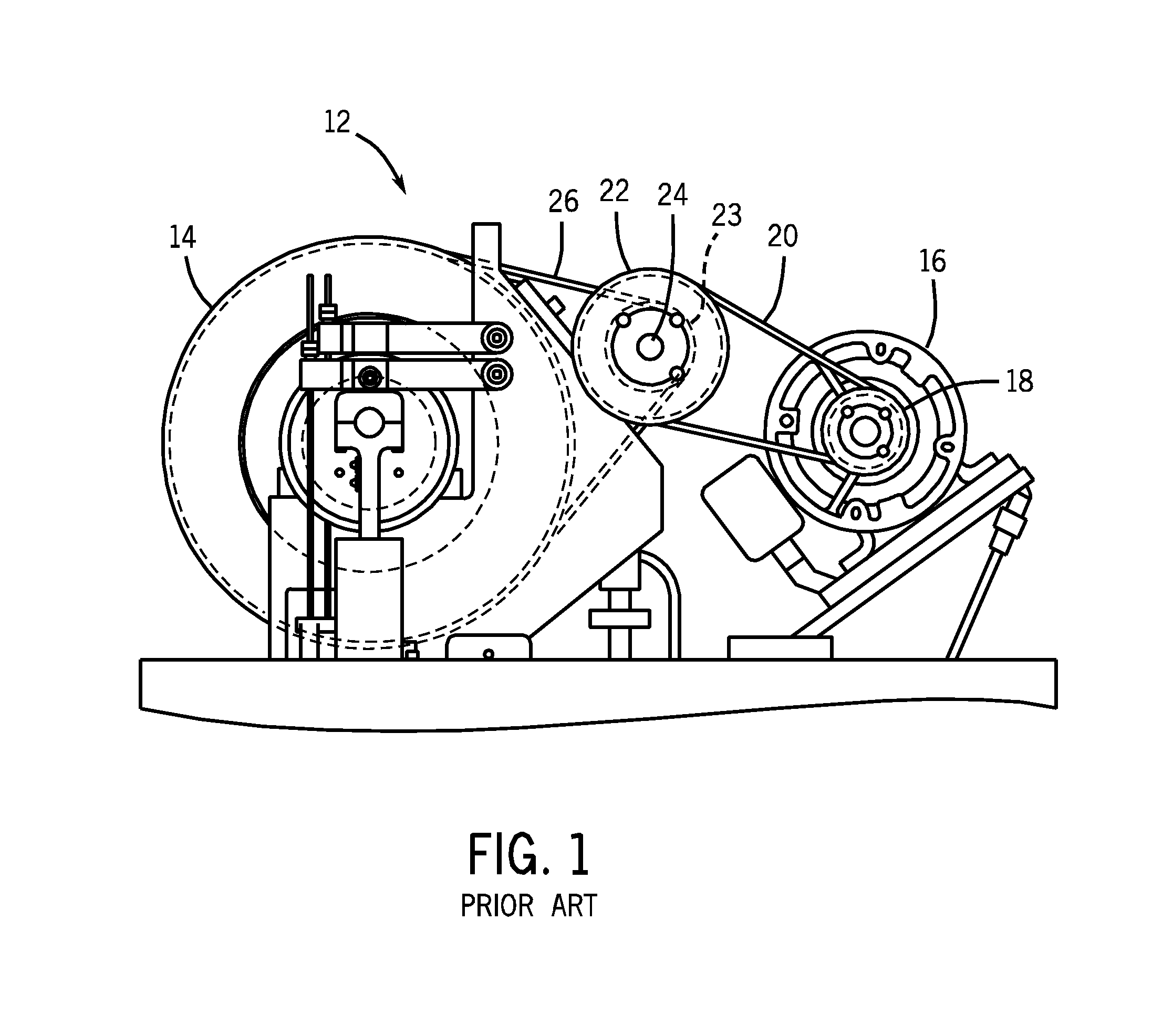

a cryogenic piston and expander technology, applied in the direction of reciprocating piston engines, machines/engines, positive displacement engines, etc., can solve the problems of belt dusting, frequent maintenance, and large amount of inertia of conventional cryogenic piston expanders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The following detailed description is of the best currently contemplated modes of carrying out exemplary embodiments of the invention. The description is not to be taken in a limiting sense, but is made merely for the purpose of illustrating the general principles of the invention, since the scope of the invention is best defined by the appended claims.

[0013]Various inventive features are described below that can each be used independently of one another or in combination with other features.

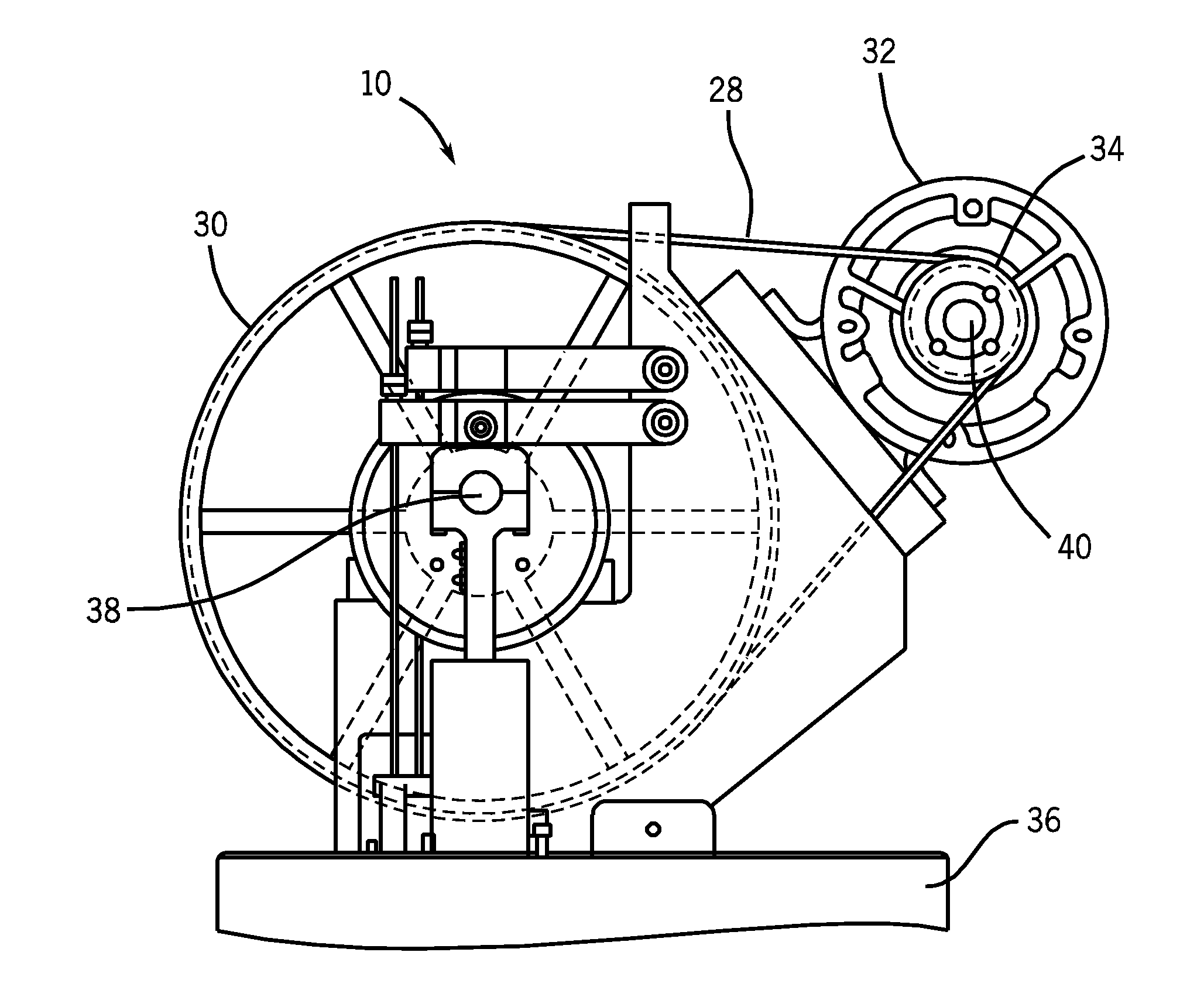

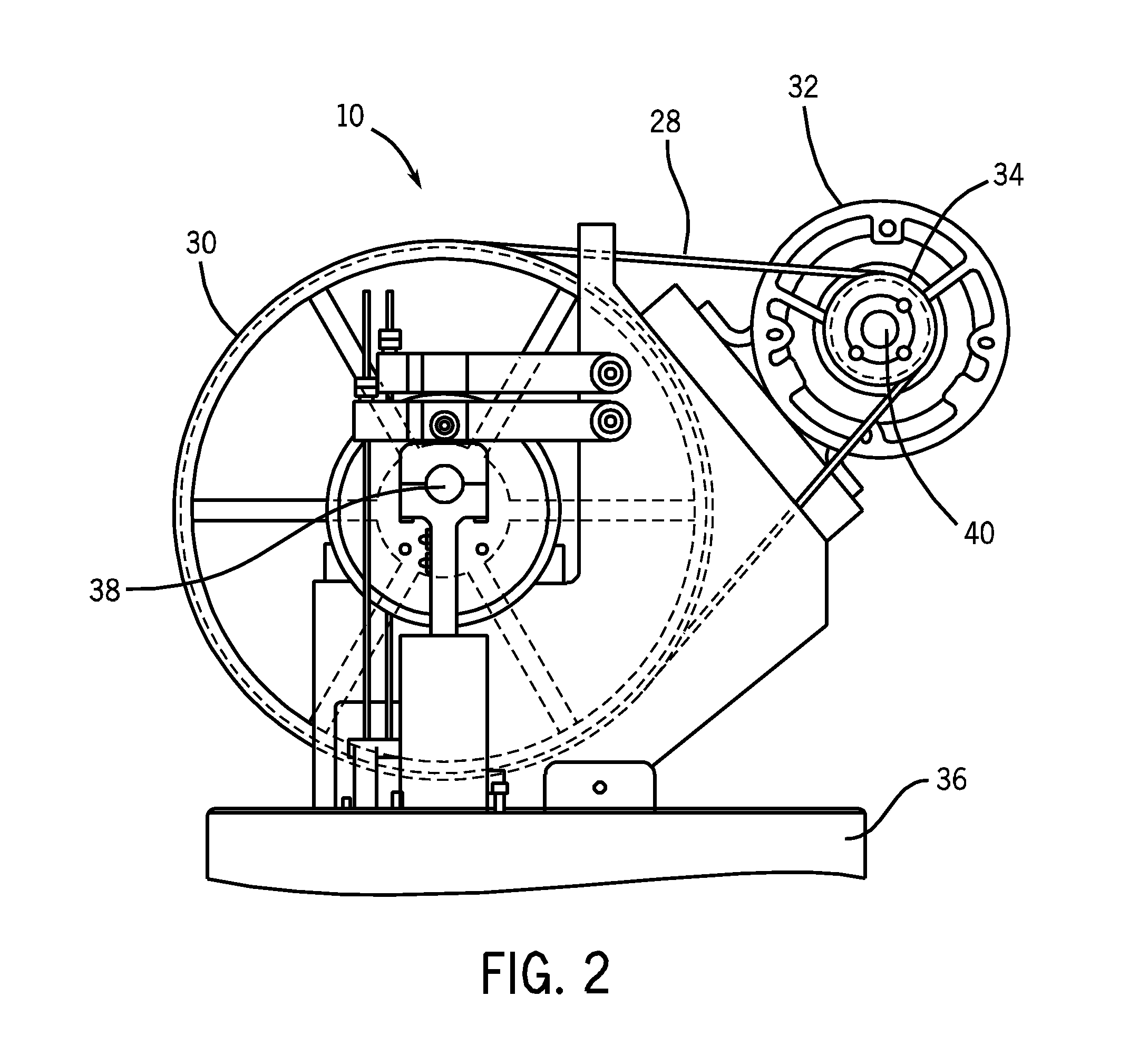

[0014]Broadly, an embodiment of the present invention provides a cryogenic piston expander may reduce or eliminate the inertia of the system, as compared to conventional cryogenic piston expanders. The cryogenic piston expander of the present invention may use a single bent running from a motor to a large sprocket mounted on a main shaft of the cryogenic piston expander.

[0015]Referring to FIG. 2, a cryogenic piston expander 10 may include a motor 32 mounted off a base plate 36 of the cryog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com