Flexing Tool and Tool Head

a tool head and tool head technology, applied in the field of hand tools and power tool attachments, can solve the problems of few tools, work surfaces, and normal vacuum cleaner attachments that are great for floors, but not as useful for couches and chairs, and achieve the effect of facilitating us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

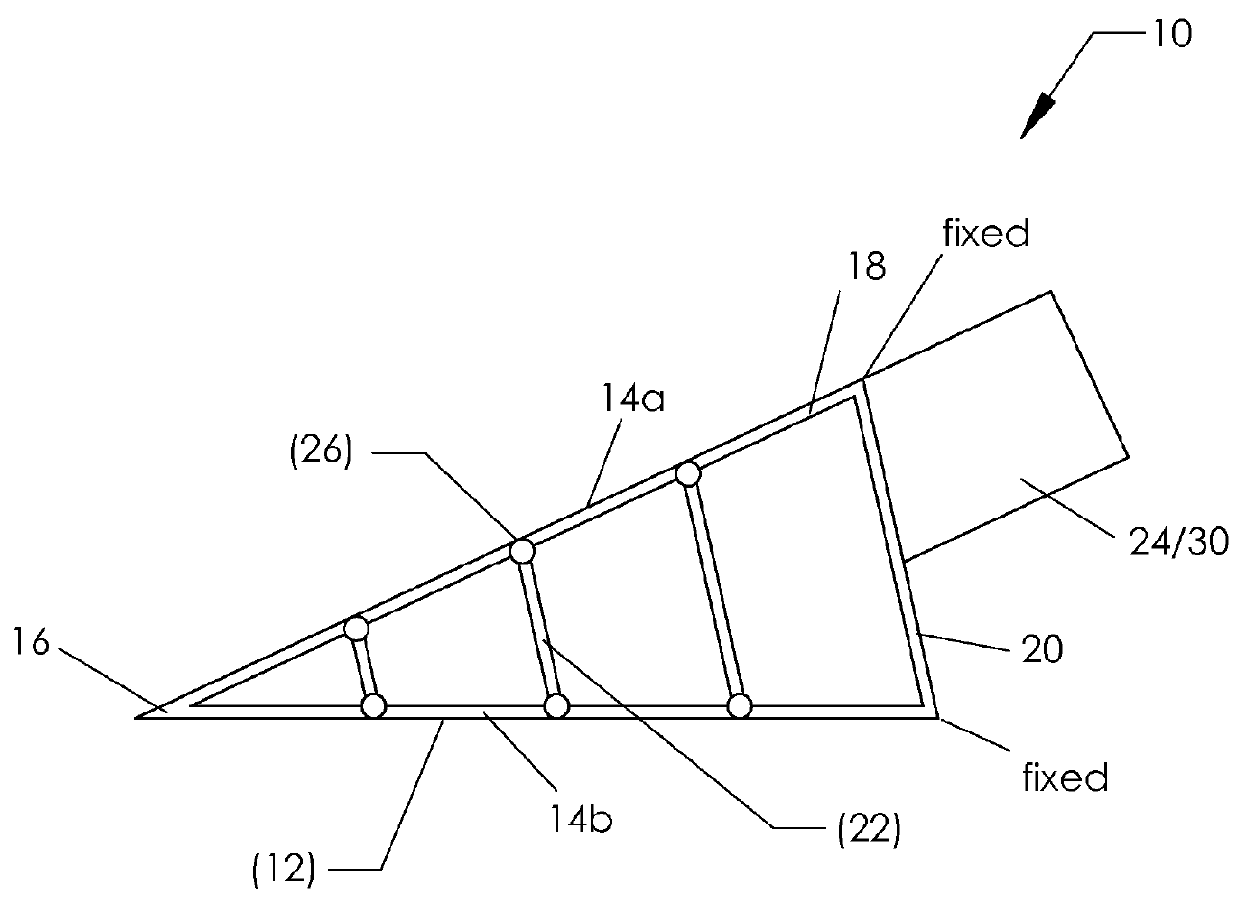

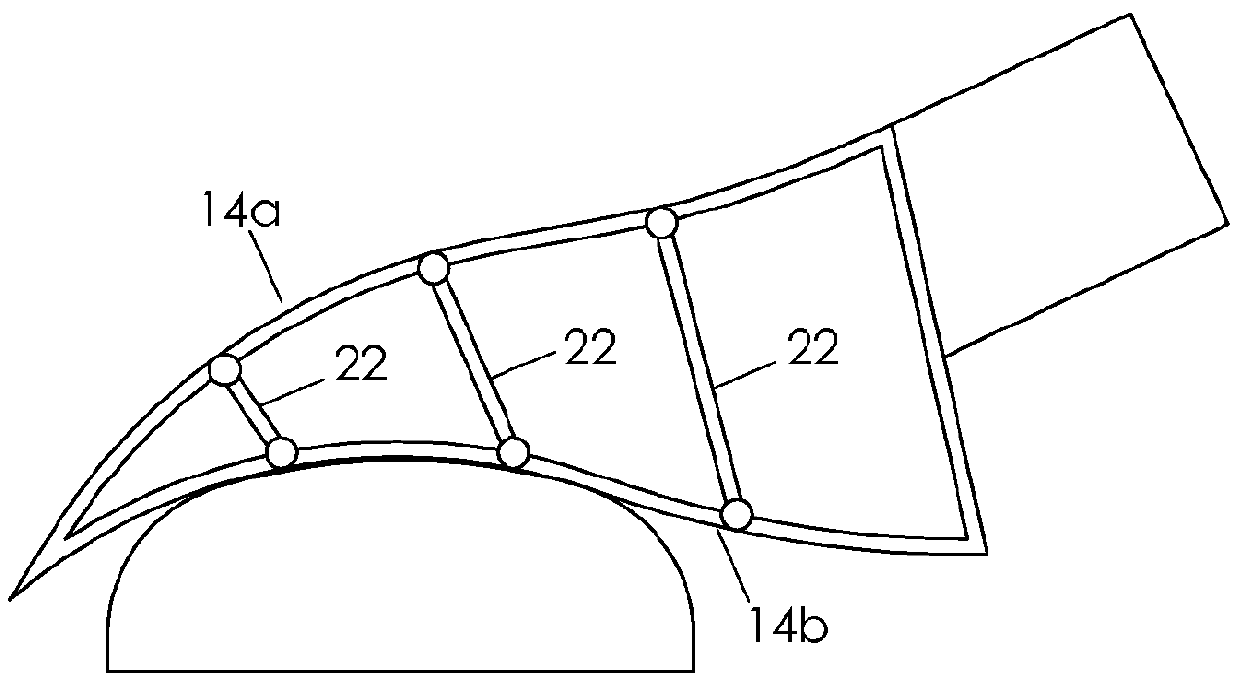

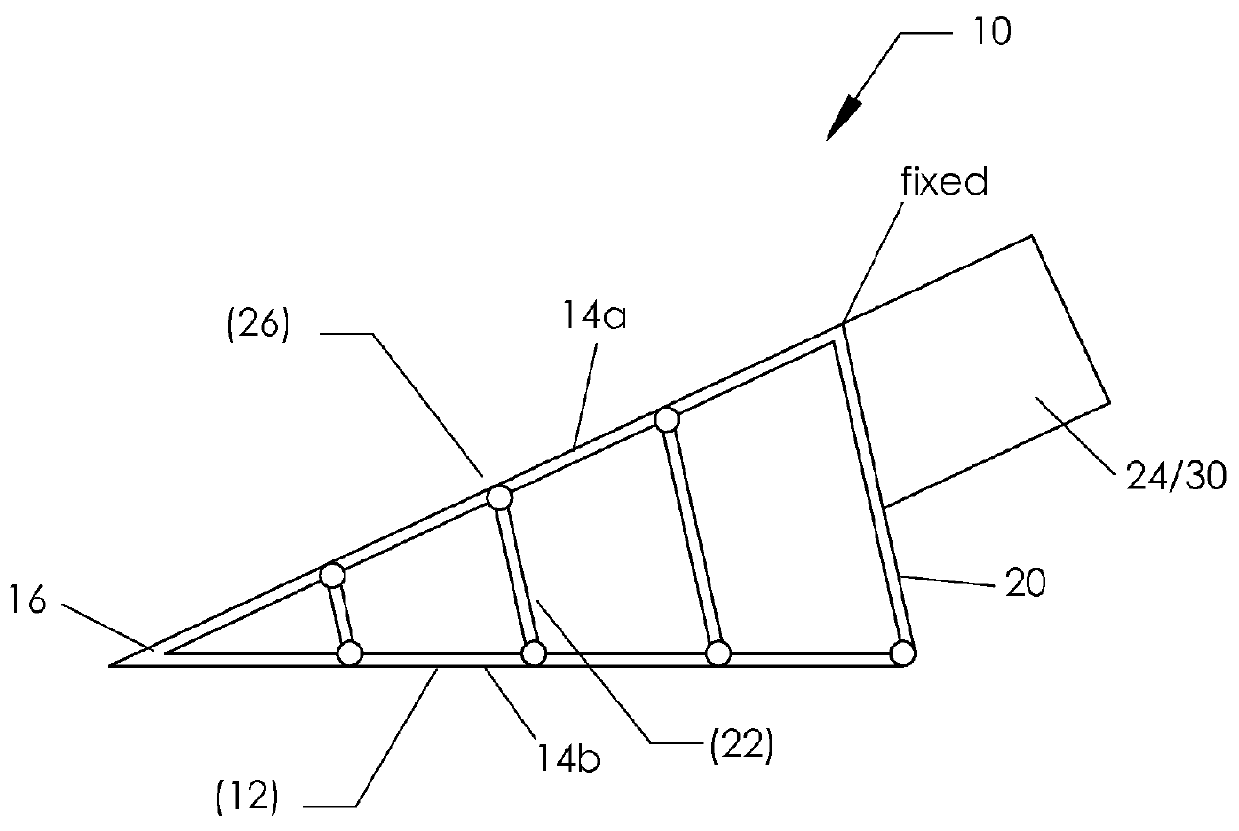

[0034]While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail, preferred embodiments of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to embodiments illustrated.

[0035]Specifically, numerical descriptions (e.g., as to size, quantity, etc.) and material compositions (e.g., plastics, wood, metals, etc.) are not to be taken in any way as fixed limitations on the scope of the invention unless clearly stated as such. The invention is primarily described in the following text and drawings with regard to embodiment as a flexible tool or flexible attachment head for a tool. However, the disclosed devices can be implemented in innumerable ways and forms, including varying sizes, shapes, dimensions, and materials. Those skilled in the art would cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com