Humeral joint replacement component

a technology for humeral joints and components, applied in the field of humeral joint replacement components, can solve the problems of increasing the stress per unit area, increasing the wear potential, and limiting the material to metal on plastic, so as to increase the options of the practitioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

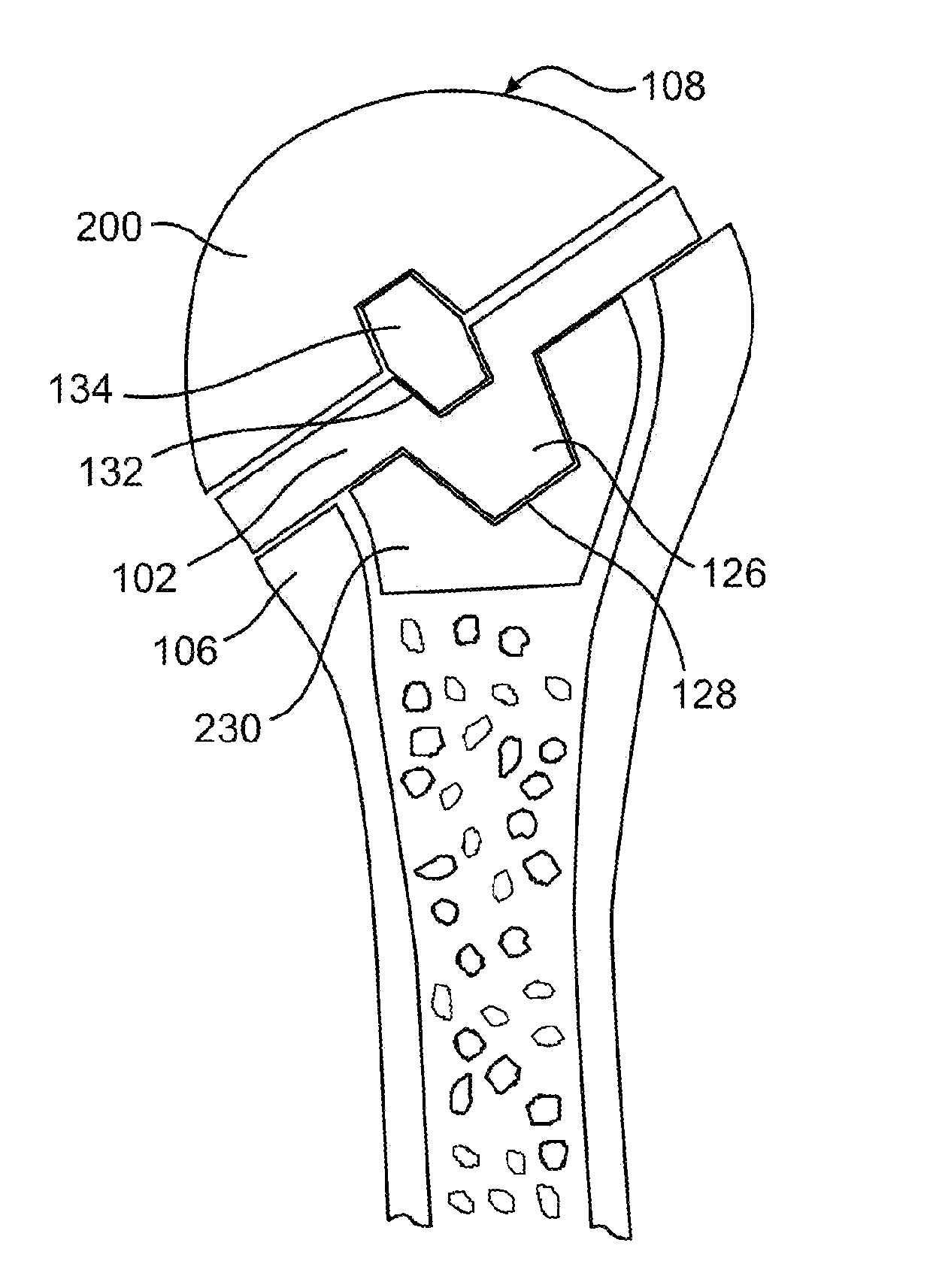

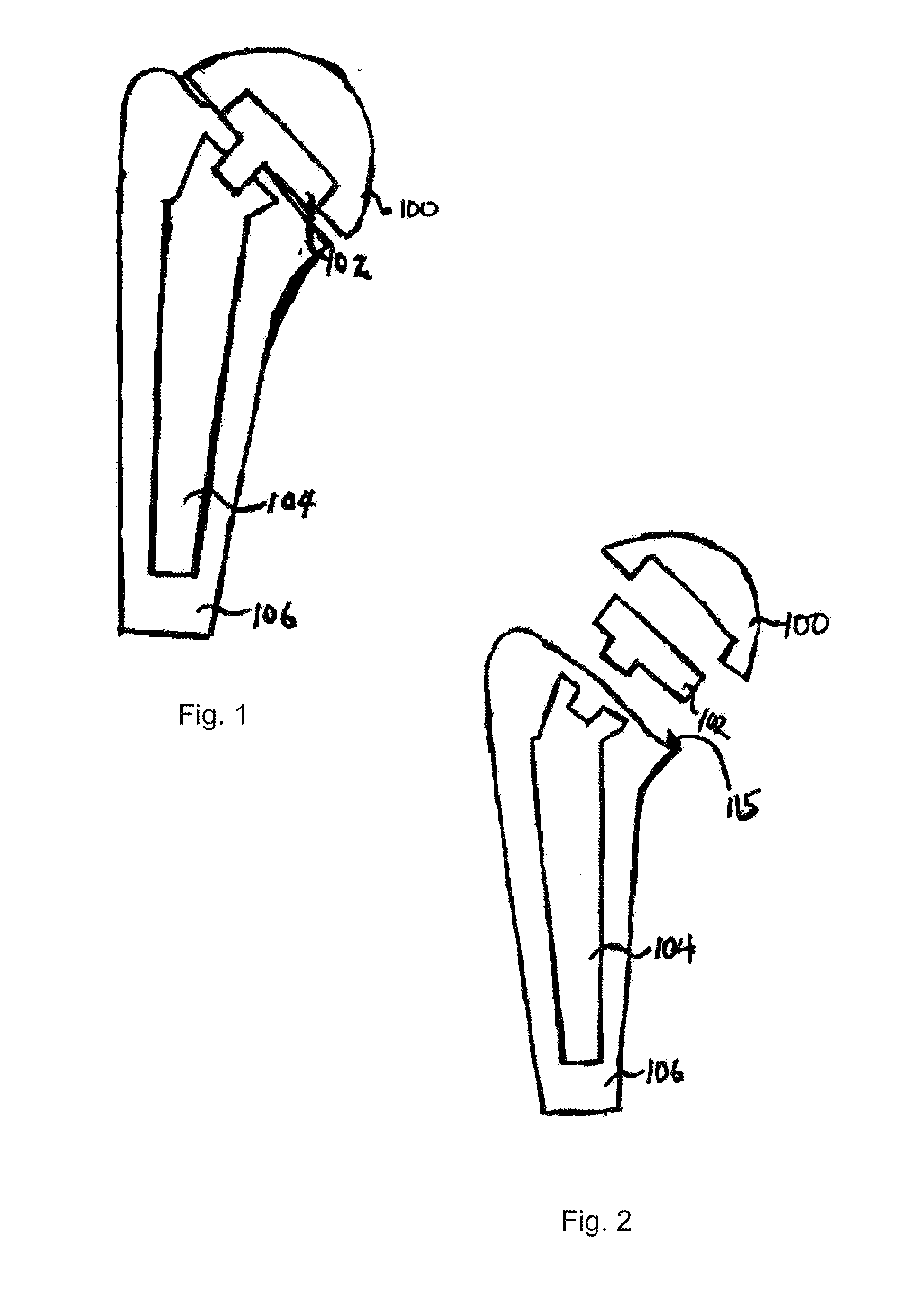

[0065]Referring to FIGS. 1-23A, the present invention provides a humeral prosthetic head 100 having an articulation surface 108 of a semi-ellipsoid that is designed to be in communication with an intermediate component 102. Intermediate component 102 serves as an interface between head 100 and a prosthetic stem 104. Stem 104 is fixed within the metaphyseal and / or diaphyseal part of a humeral shaft 106. This fixation of stem 104 within humeral shaft 106 is achieved by art-disclosed means such as press fit, porous coated biologic fixation, cement fixation, combinations thereof, or other mechanisms. Intermediate component 102 engages with both head 100 and stem 104 as shown in FIGS. 1 and 18.

[0066]The stem 104 can be any art-disclosed prosthetic stem designed to be placed in humeral shaft 106. Stem 104 can be a unitary structure as shown in FIGS. 1-2 and 18. Alternatively, stem 104 can be constructed out of modular components (not shown).

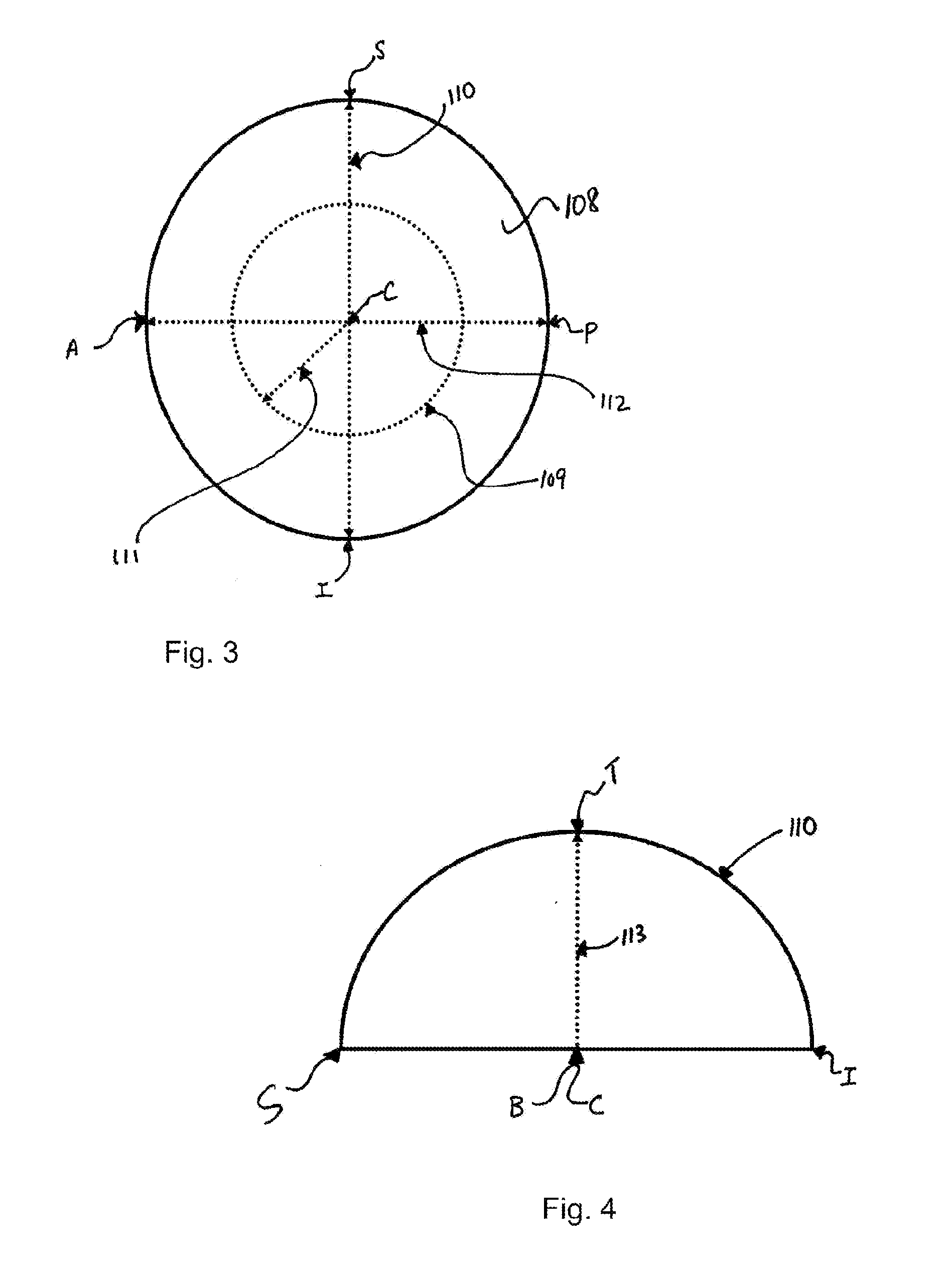

[0067]Referring to FIGS. 3-6, head 100 has artic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com